Polyaniline and manganese dioxide nanocomposite material and its preparation method and application

A nano-composite material, manganese dioxide technology, applied in the field of polyaniline and manganese dioxide nano-composite materials and their preparation, can solve the problems of unsatisfactory performance, high cost, large pollution, etc., and achieves avoiding crystal transformation and high stability. The effect of good stability and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

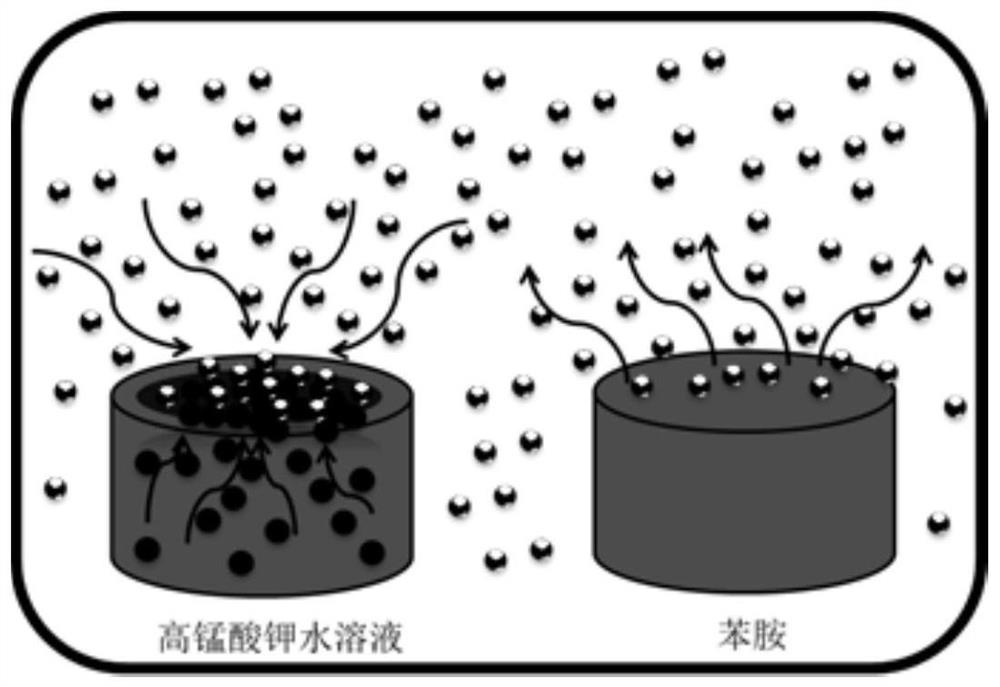

[0033] 10 g of potassium permanganate was added to 400 mL of deionized water, and stirred completely dissolved. Alternative 30ml of aniline is used. The above-mentioned potassium permanganate aqueous solution was separated from aniline in the same sealed reaction chamber, and the volatilized aniline gas was reacted on the gas-liquid interface of the gas-liquid interface. At room temperature, it was allowed to react for 12 hours. The product was then centrifuged, washed, dried to obtain polyaniline and manganese dioxide nanocomposites.

Embodiment 2

[0035] 8 g of potassium permanganate was added to 400 ml of deionized water, and stirred completely dissolved. Another 25 ml of aniline is treated. The above-mentioned potassium permanganate aqueous solution was separated from aniline in the same sealed reaction chamber, and the volatilized aniline gas was reacted on the gas-liquid interface of the gas-liquid interface. At room temperature, it was allowed to react for 12 hours. The product was then centrifuged, washed, dried to obtain polyaniline and manganese dioxide nanocomposites.

Embodiment 3

[0037] 4 g of potassium permanganate was added to 400 ml of deionized water, and stirred completely dissolved. Another 15 ml of aniline is used. The above-mentioned potassium permanganate aqueous solution was separated from aniline in the same sealed reaction chamber, and the volatilized aniline gas was reacted on the gas-liquid interface of the gas-liquid interface. At room temperature, it was allowed to react for 12 hours. The product was then centrifuged, washed, dried to obtain polyaniline and manganese dioxide nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com