Aluminum alloy for petroleum drill rod, manufacturing method of pipe thereof and pipe for petroleum drill rod

An oil drill pipe and aluminum alloy technology, which is applied in the field of aluminum alloy, can solve the problems of late start of research on aluminum alloy drill pipe technology, product dependence, and restrictions on the development of the oil drilling field, and achieve pinning dislocation suppression, strength and corrosion resistance Enhanced performance and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

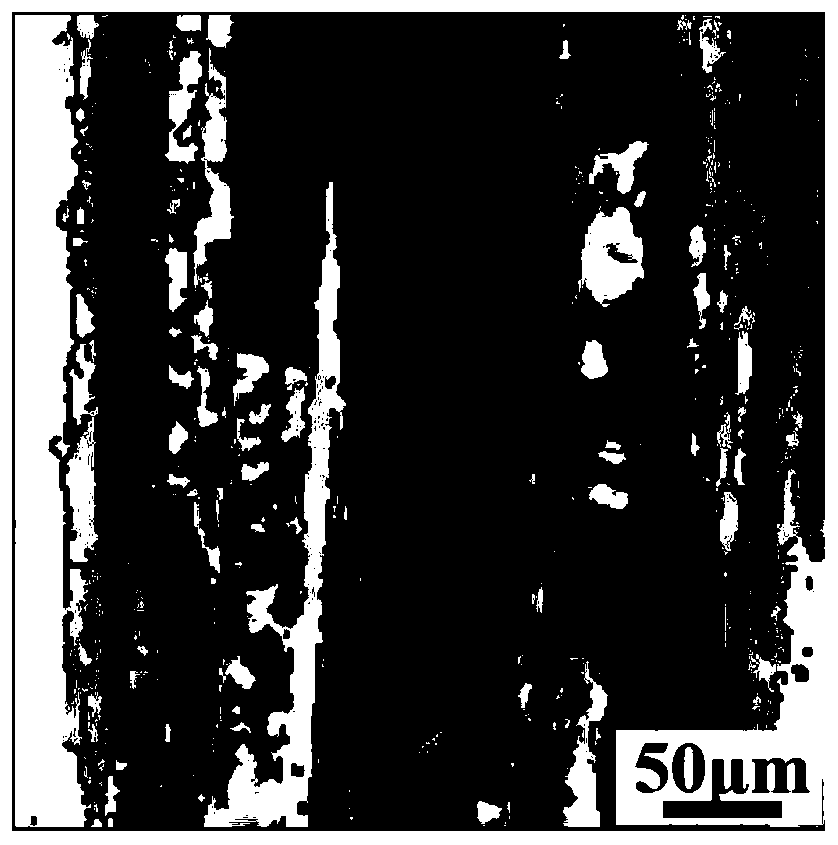

Embodiment 1

[0036] Preparation of pipes for petroleum drill pipes

[0037] (1) After smelting, refining, and casting, an aluminum alloy ingot is obtained. The aluminum alloy ingot is composed of the following components in terms of mass percentage: Zn: 6.0%, Mg: 1.7%, Cu: 1.2%, and Mn: 0.3 %, Cr: 0.16%, Er: 0.08%, Zr: 0.08%, Ti: 0.05%, the total amount of unavoidable impurities is ≤0.1%, and the balance is Al;

[0038] (2) The ingot obtained in step (1) is kept at 320°C for 10 hours and then heated to 460°C for 36 hours;

[0039] (3) Extruding the ingot processed in step (2) into a tube at a speed of 0.8m / min at 400°C;

[0040] (4) After straightening 0.8% of the tube blank obtained in step (3), first heat it up to 425°C at a rate of 40°C / h / after holding for 1 hour, and then at a speed of 40°C / h to 470°C / after holding 1.5h;

[0041] (5) The tube blank treated in step (4) is first heated to 105°C at a rate of 40°C / h, kept for 32 hours and then water quenched to room temperature, then heated to 175...

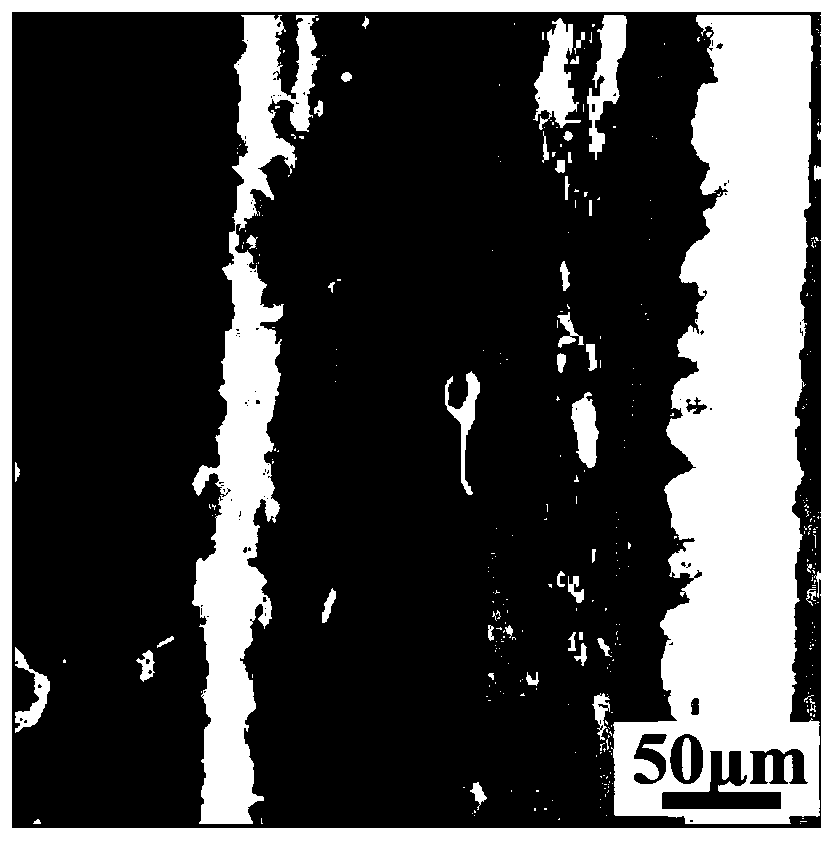

Embodiment 2

[0043] Preparation of pipes for petroleum drill pipes

[0044] (1) After smelting, refining, and casting, an aluminum alloy ingot is obtained. The aluminum alloy ingot is composed of the following components in terms of mass percentage: Zn: 6.2%, Mg: 1.8%, Cu: 1.3%, and Mn: 0.3 %, Cr: 0.15%, Er: 0.1%, Zr: 0.08%, Ti: 0.05%, the total amount of unavoidable impurities is ≤0.1%, and the balance is Al;

[0045] (2) The ingot obtained in step (1) is kept at 350°C for 10 hours and then heated to 470°C for 24 hours;

[0046] (3) Extruding the ingot processed in step (2) into a tube at a speed of 0.6m / min at 400°C;

[0047] (4) After 1% straightening of the tube blank obtained in step (3), the temperature is raised to 420°C at a rate of 35°C / h / after heat preservation for 2h, and then at a rate of 35°C / h to 465°C / after heat preservation 1h;

[0048] (5) The tube blank treated in step (4) is first heated to 100°C at a rate of 35°C / h, kept for 36 hours and then water quenched to room temperature,...

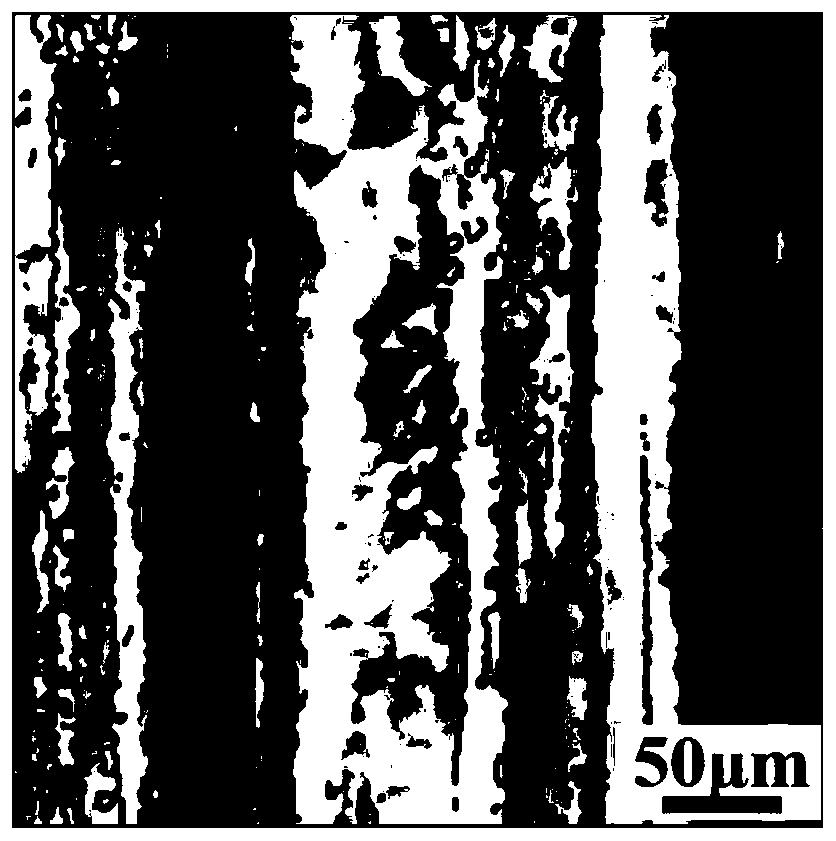

Embodiment 3

[0050] Preparation of pipes for petroleum drill pipes

[0051] (1) After smelting, refining, and casting, an aluminum alloy ingot is obtained. The aluminum alloy ingot is composed of the following components in terms of mass percentage: Zn: 5.9%, Mg: 1.8%, Cu: 1.1%, and Mn: 0.32 %, Cr: 0.15%, Er: 0.13%, Zr: 0.06%, Ti: 0.05%, the total amount of unavoidable impurities is ≤0.1%, and the balance is Al;

[0052] (2) The ingot obtained in step (1) is kept at 300°C for 12 hours and then heated to 470°C for 24 hours;

[0053] (3) Extruding the ingot processed in step (2) into a tube at a speed of 0.5m / min at 380°C;

[0054] (4) After 1% straightening of the tube blank obtained in step (3), the temperature is raised to 420°C at a rate of 35°C / h / after heat preservation for 2h, and then at a rate of 35°C / h to 465°C / after heat preservation 2h;

[0055] (5) The tube blank treated in step (4) is first heated to 100°C at a rate of 35°C / h, kept for 36 hours and then water quenched to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com