Dirac node ball semimetal and preparation and application method thereof

A technology of Dirac knots and semi-metals, applied in the coating process of metal materials, nanotechnology for materials and surface science, ion implantation plating, etc., can solve the complex and lengthy problems of discovering new Dirac materials, and achieve The effect of enriching knowledge and understanding, good repeatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

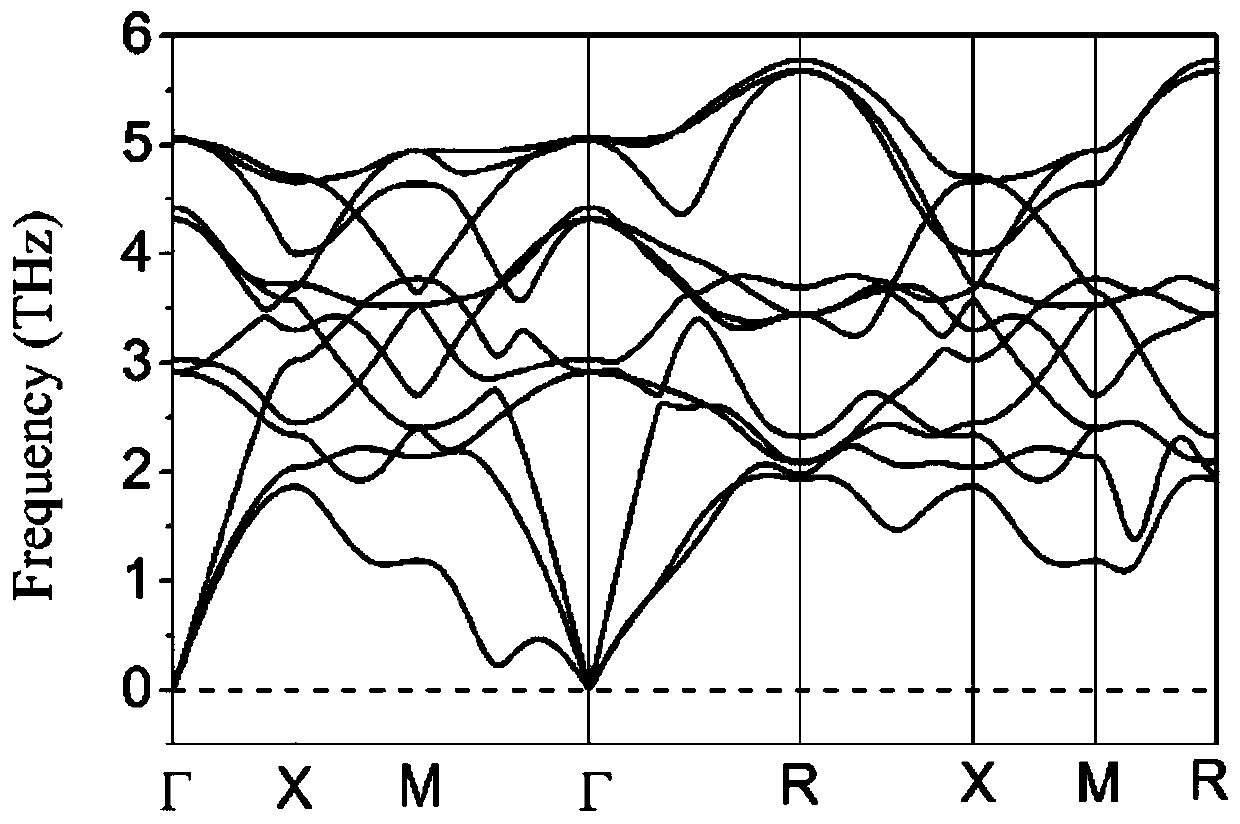

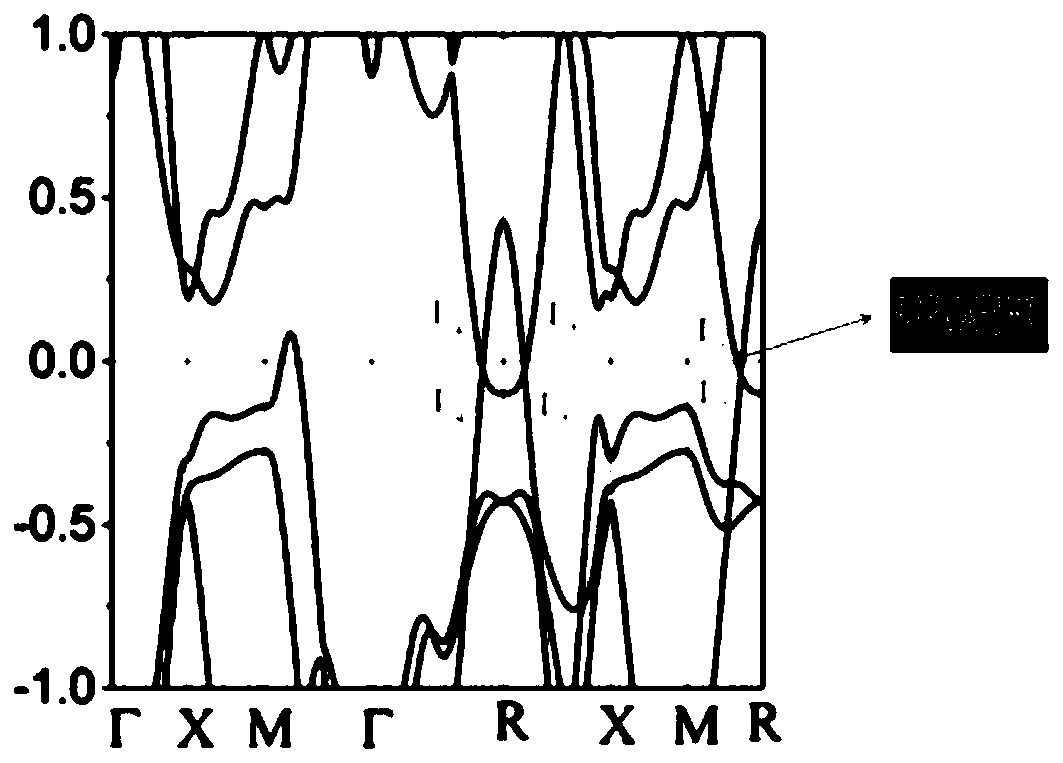

[0034] Example 1, this application uses theoretical simulation and calculation, through model construction and stability testing, energy band calculation and accurate fitting, and simulation analysis of topological characteristics, a new type of Dirac nodal spherical semimetal and its preparation are proposed method.

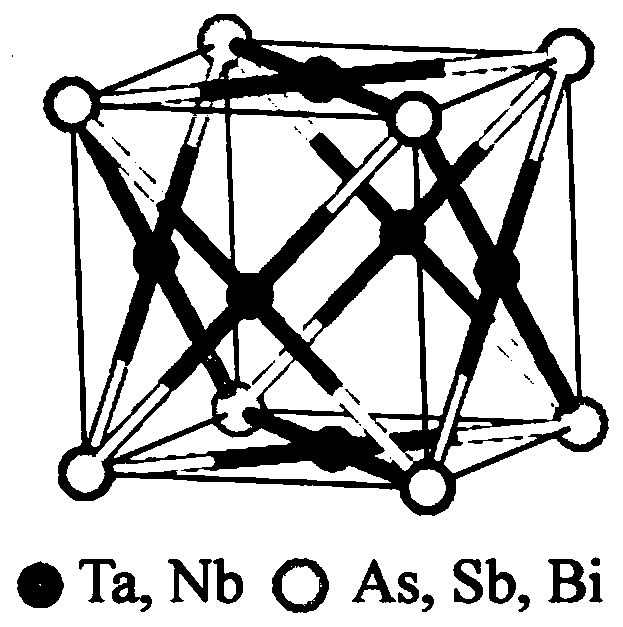

[0035] like figure 1 As shown, the crystal structure of the Dirac nodal semimetal is Cu in the ordered L12 phase 3 Au is the basic structure, and the group VB transition metal atoms X (Nb, Ta) and the V main group atoms Y (As, Sb, Bi) form a face-centered cubic structure (fcc) simulation material X 3 Y.

[0036] Among them, the atoms at the face center are transition metal atoms X of Group VB (such as Nb, Ta), and the atoms at the 8 vertices are the atoms of Group V main group Y (such as As, Sb, Bi).

[0037] The above-mentioned X composed of transition metal atom X of group VB and atom Y of main group V 3 Y alloy material, which belongs to a new type of Dira...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com