De-acidification reinforcement protective agent and preparation method and applications thereof

A technology of strengthening protective agent and deacidification, which is applied in the field of restoration and protection of paper cultural relics. It can solve the problems of unfriendly environment, fading handwriting, and difficult process control, etc., and achieves simple and easy control of the operation process, uniform dispersion of the solvent system, and improved The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take 1 g of γ-aminopropyltriethoxysilane and add it to 1000 g of ultrapure water, fully stir and mix it under the assistance of 30KHz ultrasonic power and 60r / min mechanical stirring to obtain solution 1, and slowly add 1 g of nano-magnesium carbonate to solution 1. Power 30KHz ultrasonic and 60r / min mechanical stirring to obtain solution 2, slowly add 50g of toluene diisocyanate to solution 2, power 30KHz ultrasonic and 60r / min mechanical stirring to obtain solution 3, slowly add polyethylene wax emulsion 1g to solution 3 , fully stirred at 18°C and ultrasonicated for 10 minutes to obtain a deacidification strengthening and protecting agent.

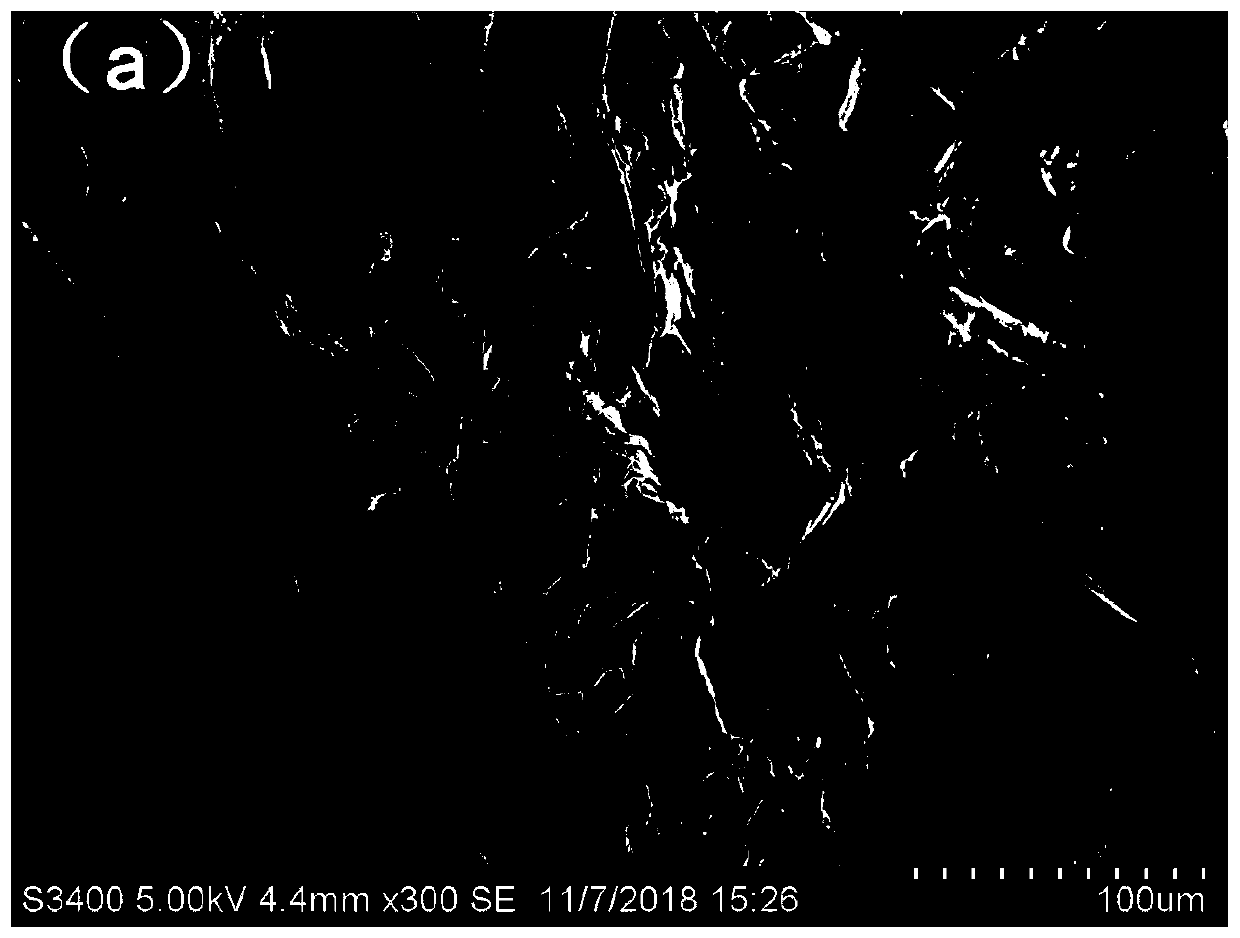

[0031] Soak 6-11 sheets of paper at room temperature and treat them with 800-1000g of the above-mentioned deacidification strengthening and protecting agent for 15 minutes, and then put them in a constant temperature and humidity environment to hang samples for drying for 24 hours, test the pH and mechanical properties of the pa...

Embodiment 2

[0033] Take 3g of N-(2-aminoethyl)-3-aminopropyltriethoxysilane and add it to 1000g ultrapure water, fully stir and mix under the power of 45KHz ultrasonic wave and 70r / min mechanical stirring to obtain solution 1, in Slowly add 5g of nano-calcium carbonate to solution 1 and mix it with 45KHz ultrasonic power and 70r / min mechanical stirring to obtain solution 2. Slowly add 80g of toluene diisocyanate to solution 2 and mix with 45KHz ultrasonic power and 70r / min mechanical stirring to obtain solution 3. Slowly add 2 g of polyethylene wax emulsion to solution 3, stir well at 30°C and perform ultrasonication for 12 minutes to obtain a deacidification strengthening and protecting agent.

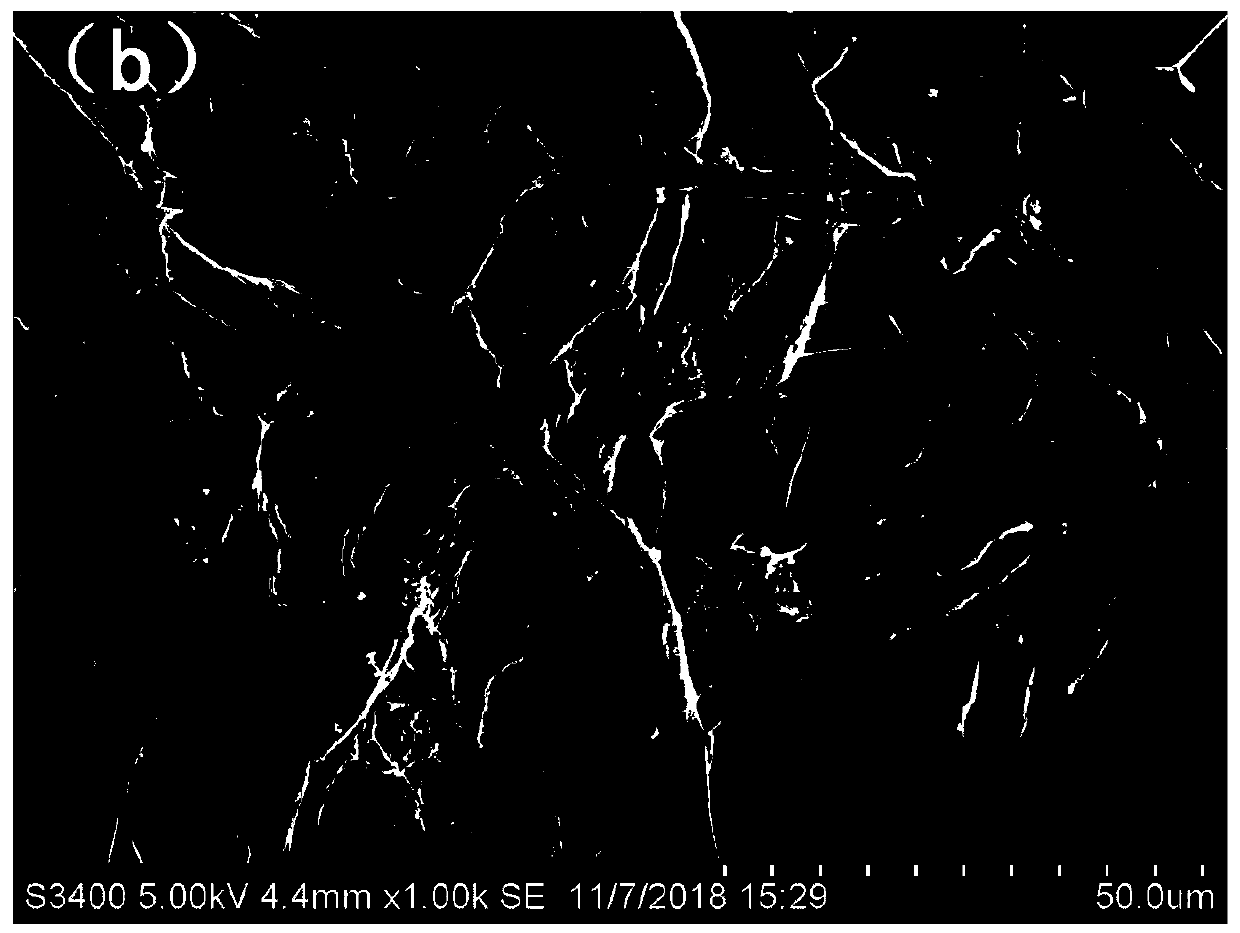

[0034] Soak 6-11 sheets of paper at room temperature and treat with 800-1000g of the above-mentioned deacidification strengthening and protecting agent for 15 minutes, then put them in a constant temperature and humidity environment to hang samples for drying for 30 hours, test the pH and mechanic...

Embodiment 3

[0036] Take 5g of N-β-(aminoethyl)-γaminopropylmethyldimethoxysilane and add it into 1000g of ultrapure water, fully stir and mix with the power of 60KHz ultrasonic wave and 80r / min mechanical stirring to obtain solution 1, In solution 1, slowly add mixed nano-magnesium carbonate 10g and nano-calcium carbonate 5g at a power of 60KHz ultrasonic and 80r / min mechanical stirring to obtain solution 2, slowly add diphenylmethane diisocyanate (MDI) 150g in solution 2 at a power of 60KHz Ultrasound and 80r / min mechanical stirring were mixed to obtain solution 3, and 3 g of polyethylene wax emulsion was slowly added to solution 3, fully stirred at 40°C and ultrasonically performed for 15 minutes to obtain a deacidification strengthening and protecting agent.

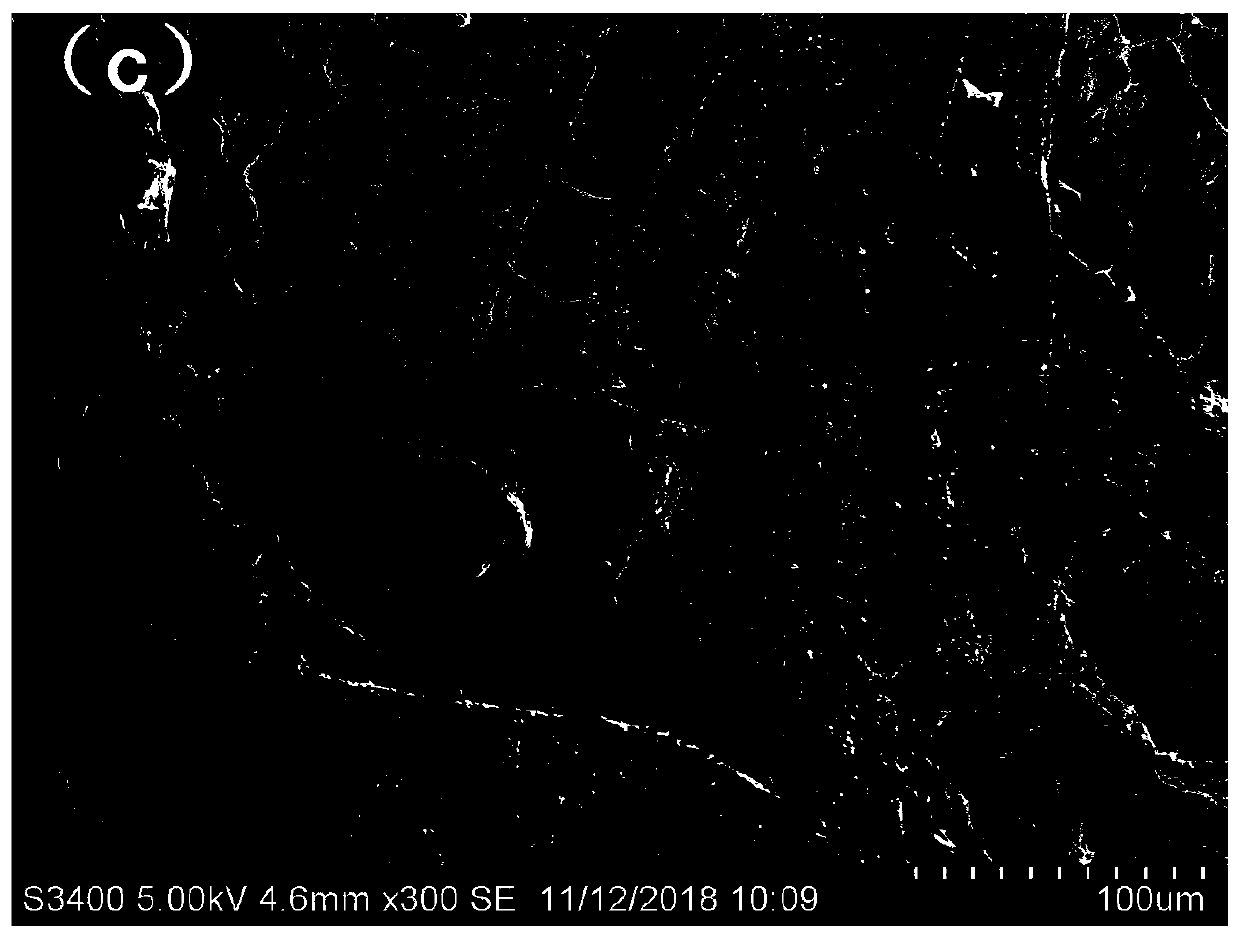

[0037]Soak 6-11 sheets of paper at room temperature and treat them with 800-1000g of the above-mentioned deacidification strengthening and protecting agent for 15 minutes, and then put them in a constant temperature and humidity e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com