Pervious concrete pavement brick and manufacturing method thereof

A technology for permeable concrete and a manufacturing method, which is applied to manufacturing tools, clay preparation devices, chemical instruments and methods, etc., can solve the problems of porous cement concrete pores being easily blocked, affecting the permeable effect and service life, and difficulty in dredging management, etc. The effect of solving the problem of blocking maintenance and cleaning, simple manufacturing process, and reducing labor intensity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

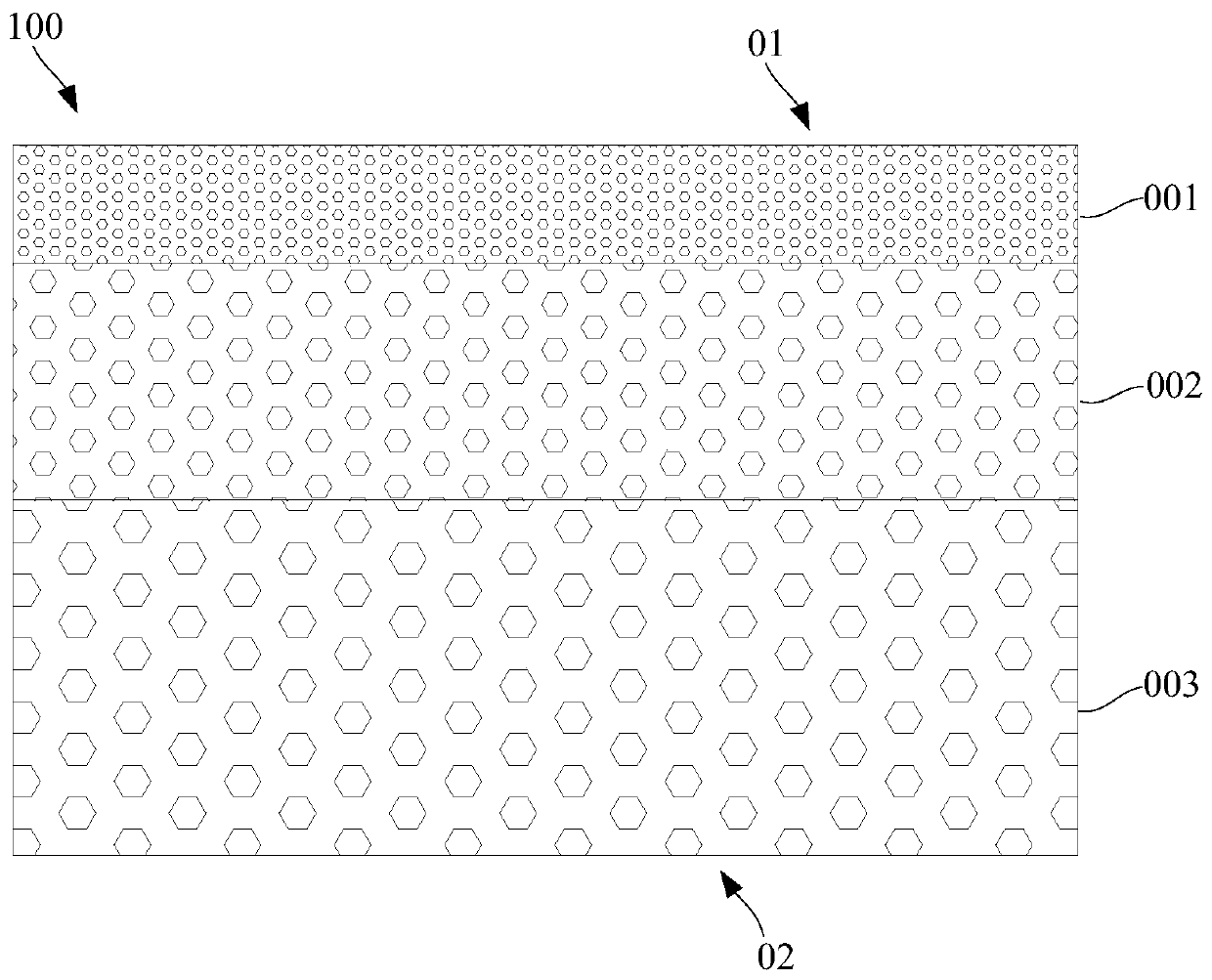

[0039] This embodiment provides a permeable concrete pavement brick. The permeable concrete pavement brick includes a multi-layer structure, and the permeable concrete pavement brick with the multi-layer structure has a gradient hole structure. For example, in the preferred embodiment of this embodiment, such as figure 1 As shown, the permeable concrete pavement brick 100 includes a three-layer structure, from the surface layer 01 of the permeable concrete pavement brick 100 (that is, the exposed side when laid on the road surface) to the bottom layer 02 (that is, the side that is in contact with the road surface when laid on the road surface) ) are: the first layer structure 001, the second layer structure 002 and the third layer structure 003. And the water permeability of the first layer structure 001, the second layer structure 002 and the third layer structure 003 increases successively. Preferably, the first water permeability coefficient of the first layer structure 00...

Embodiment 2

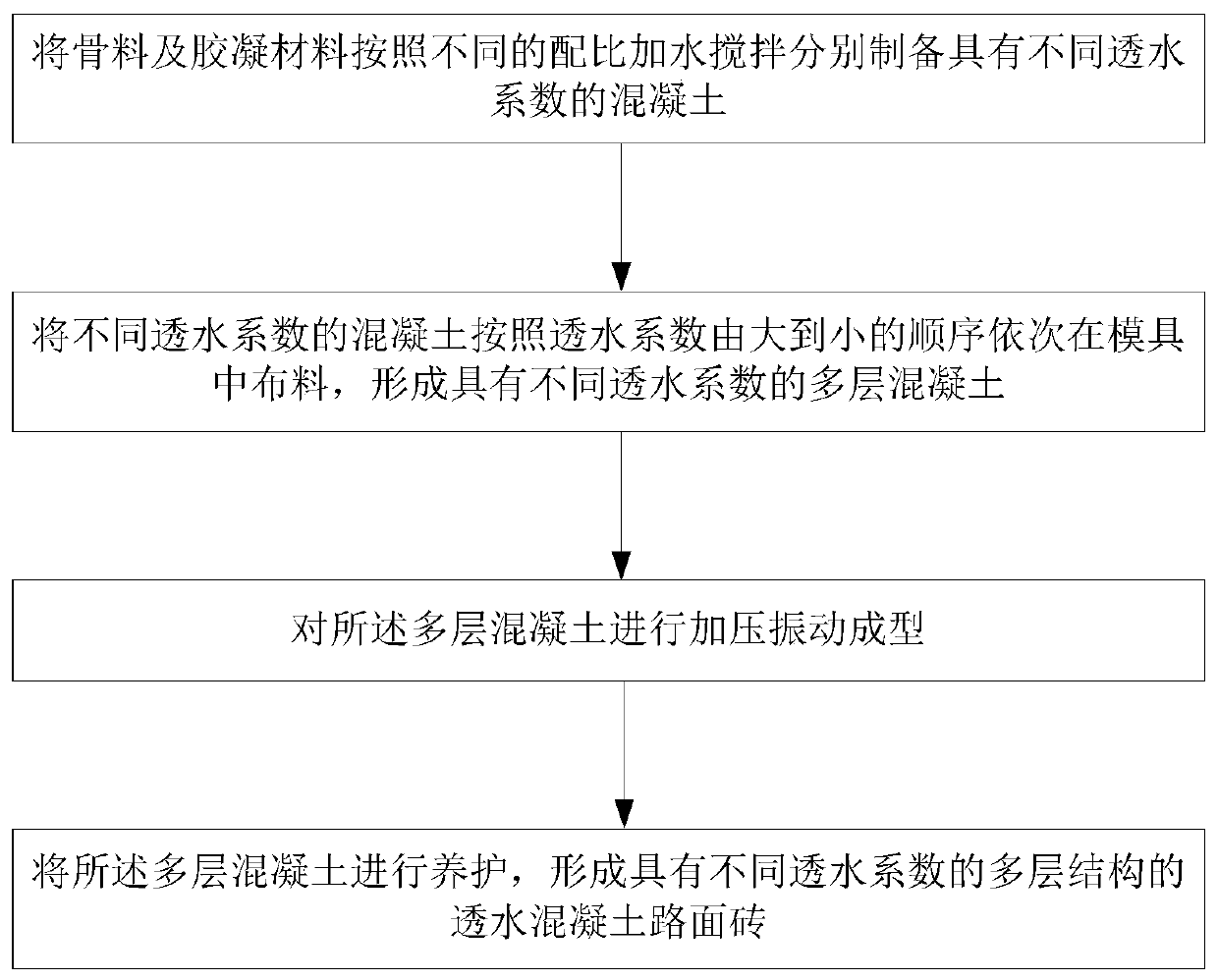

[0044] This embodiment provides a method for manufacturing permeable concrete pavement bricks, such as figure 2 As shown, the method includes the following steps:

[0045] S01: Aggregate and cementitious materials are mixed with water according to different ratios to prepare concrete with different water permeability coefficients;

[0046] In this embodiment, sand (or stones) with particle sizes between 0.5-0.9mm, 1.2-1.8mm and 2.4-4mm are selected as aggregates, PC52.5 Portland cement or PC52.5 silicic acid Salt cement and silica fume are used as cementitious materials. The aggregate cementitious material and water are mixed according to different proportions, and then stirred in a mixer to prepare concrete with different water permeability coefficients. More preferably, the following additives can also be optionally added: a water reducer accounting for 1.5-3% of the weight of the above-mentioned gelling material, an acrylate salt accounting for 0.5-3% of the weight of th...

Embodiment 3

[0069] This embodiment provides a method for manufacturing permeable concrete pavement bricks, and the similarities with Embodiment 2 will not be repeated, and the difference lies in:

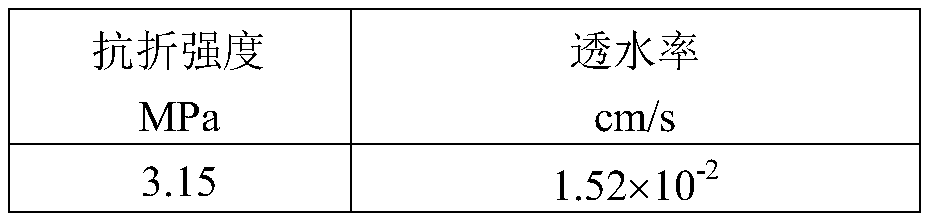

[0070] In this example, 1250g of aggregate with a particle size between 0.5 and 0.9mm, 500g of PC52.5 portland cement, 14g of silica fume, and 231.3ml of water were weighed for proportioning, and after stirring, a cement with the first water permeability coefficient was obtained. The first concrete, the first water permeability coefficient is greater than or equal to 1×10 -2 cm / s; more preferably, when forming the above-mentioned second concrete, add 7.71g of water reducer, 10.3g of calcium acrylate, and 15.45mg of ammonium persulfate.

[0071] Weigh 1250 aggregates with a particle size ranging from 1.2 to 1.8 mm, 450 g of PC52.5 cement, and 202.5 ml of water for proportioning. After stirring, the second concrete with the second water permeability coefficient is obtained, and the first water pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com