Layered oil recovery device for petroleum deformation sleeve pipe well

A technology of layered oil production and cased well, which is applied to the valve device of wellbore/well, production fluid, earth-moving drilling and other directions, which can solve the problem that the slips cannot be anchored to the inner wall of the casing and the distance between the slips and the inner wall of the casing is large. , reducing the inner diameter and other problems, to achieve the effect of saving repair work and costs, avoiding interlayer interference, and reducing outer diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

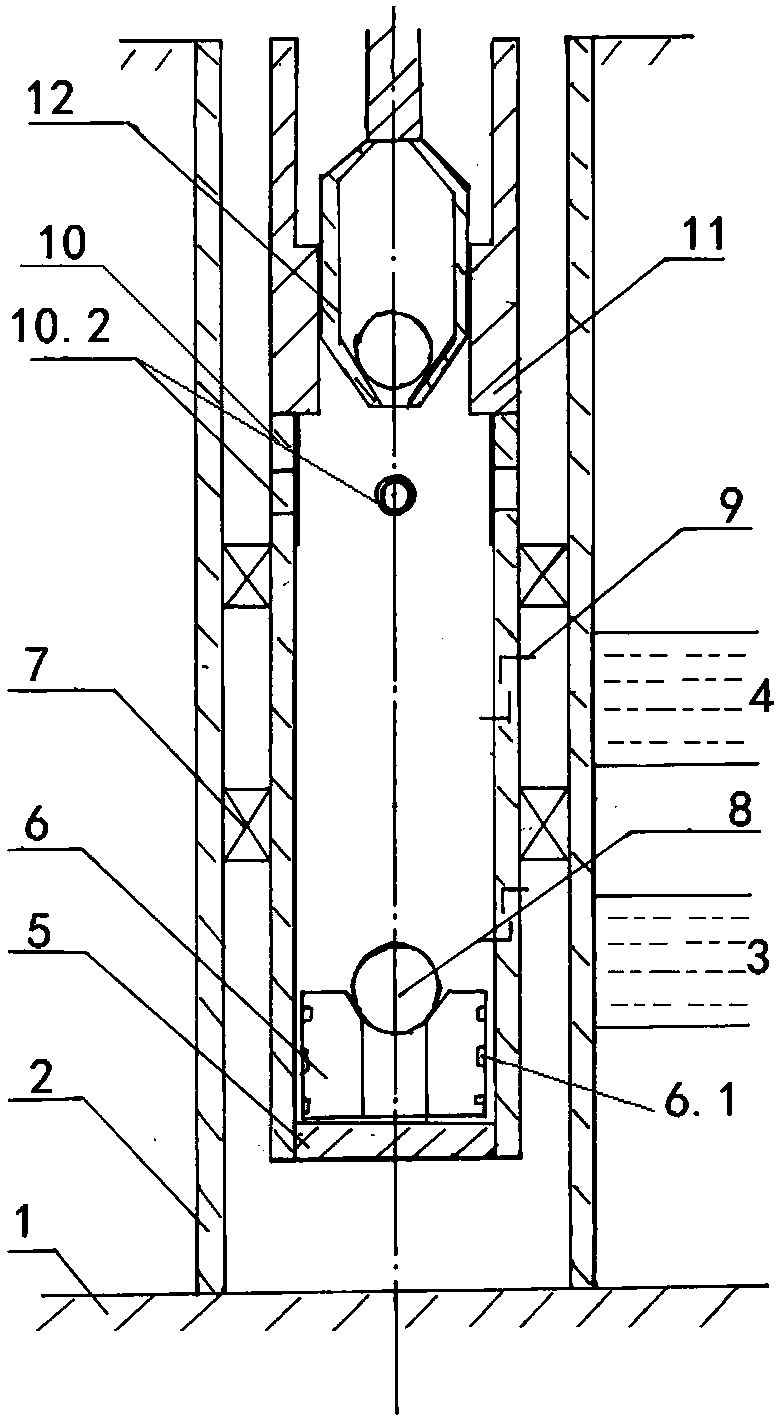

[0024] Embodiment 1, with reference to attached figure 1, a kind of petroleum deformation cased well layered oil recovery device mentioned in the present invention, including blind plug 5, first group of double hydraulic two-way anchor packer 7, first hydraulic switch 9, reversing opener 10, oil pump barrel 11. The second hydraulic switch 14, the second group of dual-hydraulic two-way anchor packers 15, the upper end of the oil well pump barrel 11 is connected to the oil pipe, the lower end is connected to the reversing opener 10, and the lower part of the reversing opener 10 is connected to the second A group of dual hydraulic bidirectional anchor packers 7, the lower part of the first group of dual hydraulic bidirectional anchor packers 7 is connected to the first hydraulic switch 9, and the lower part of the first hydraulic switch 9 passes through the second group of dual hydraulic bidirectional anchor packers. The spacer 15 is connected to the second hydraulic switch 14, a...

Embodiment 2

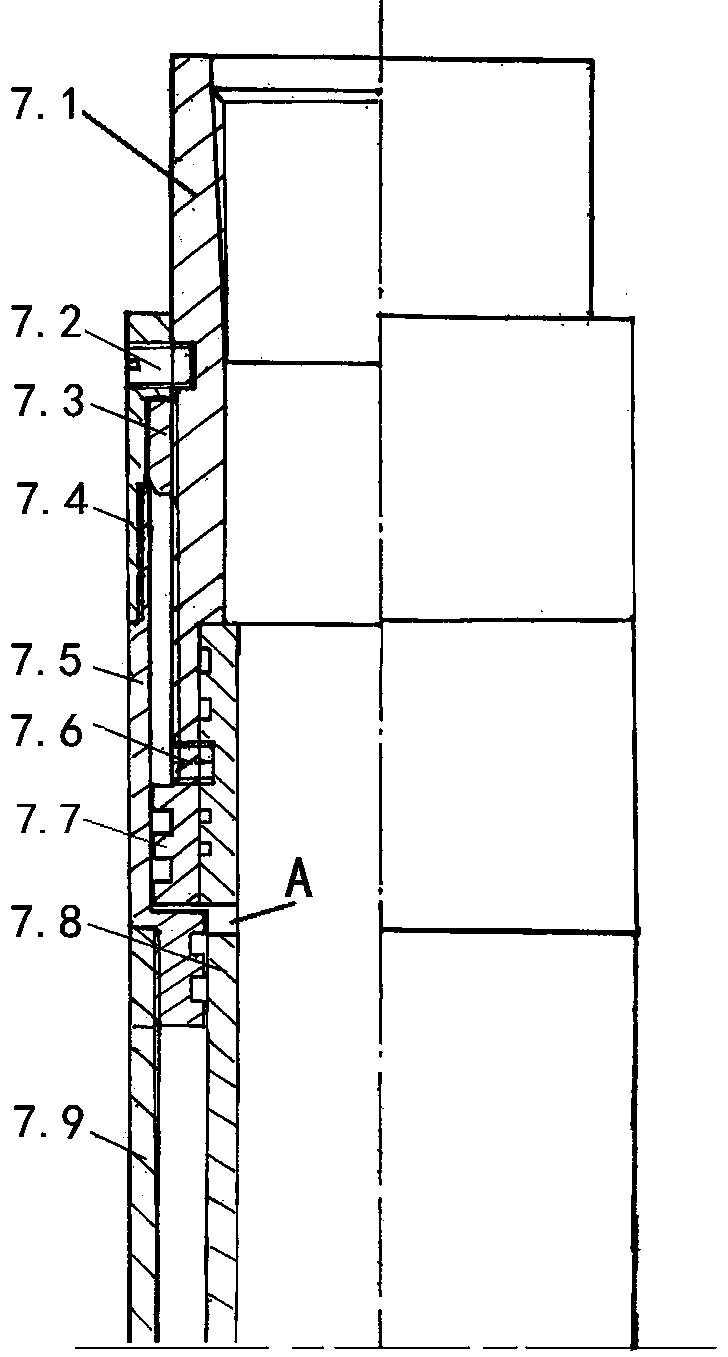

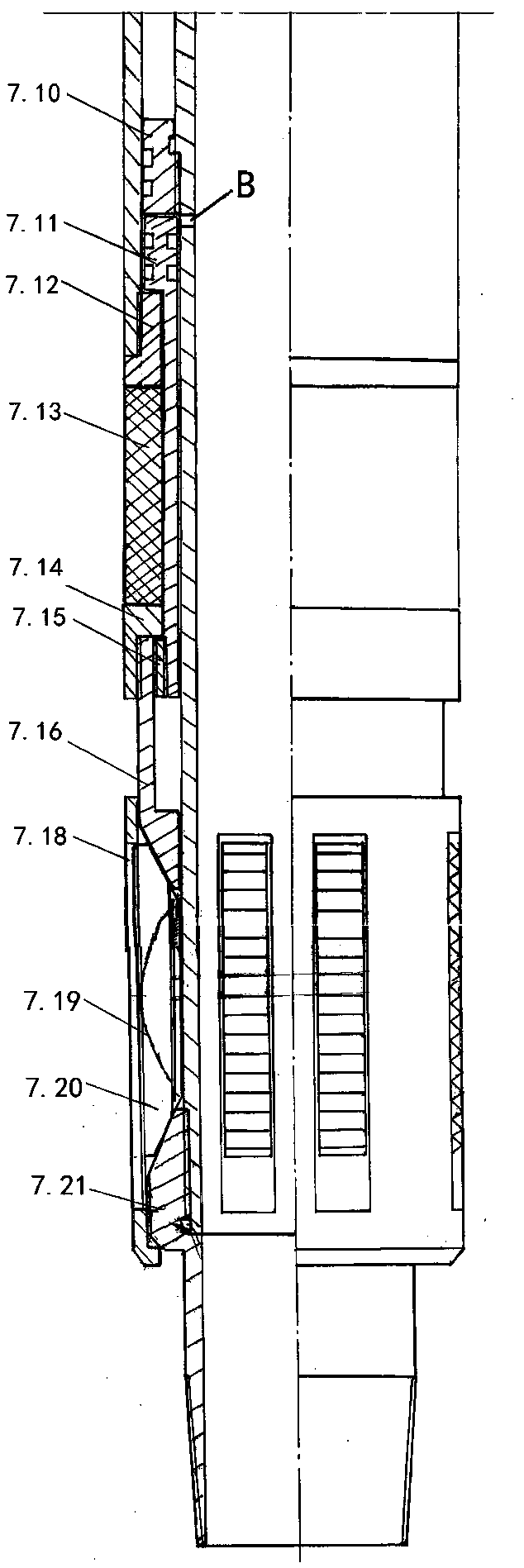

[0055] Embodiment 2, a kind of petroleum deformation cased well layered oil recovery device mentioned in the present invention, differs from Embodiment 1 in that: the first group of dual-hydraulic two-way anchor packers 7 includes upper joint 7.1, setting shear nails 7.2, lock spring 7.3, lock spring pressure cap 7.4, sealing piston 7.5, unsealing shear ring 7.17, central tube 7.8, sealing sleeve 7.9, fixed sealing ring 7.10, compensation type rubber cylinder filling tube 7.11, rubber cylinder upper pressure sleeve 7.12, Rubber cylinder 7.13, rubber cylinder lower pressure sleeve 7.14, upper cone 7.16, slip sleeve 7.18, leaf spring 7.19, slips 7.20, lower joint 7.21, the upper joint 7.1 is connected with the upper end of the central tube 7.8 through the unsealed shear ring 7.17 , the lower end of the central pipe 7.8 is connected to the lower joint 7.21, the central pipe 7.8 is provided with a first hydraulic outlet A and a second hydraulic outlet B, the outer side of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com