Semiconductor or photovoltaic material processing device

A technology of photovoltaic materials and processing devices, which is applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of large size of graphite ark, increased defective product rate, wear of sealing plates and furnace frames, etc. Compression properties and service life, the effect of improving compression resistance and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

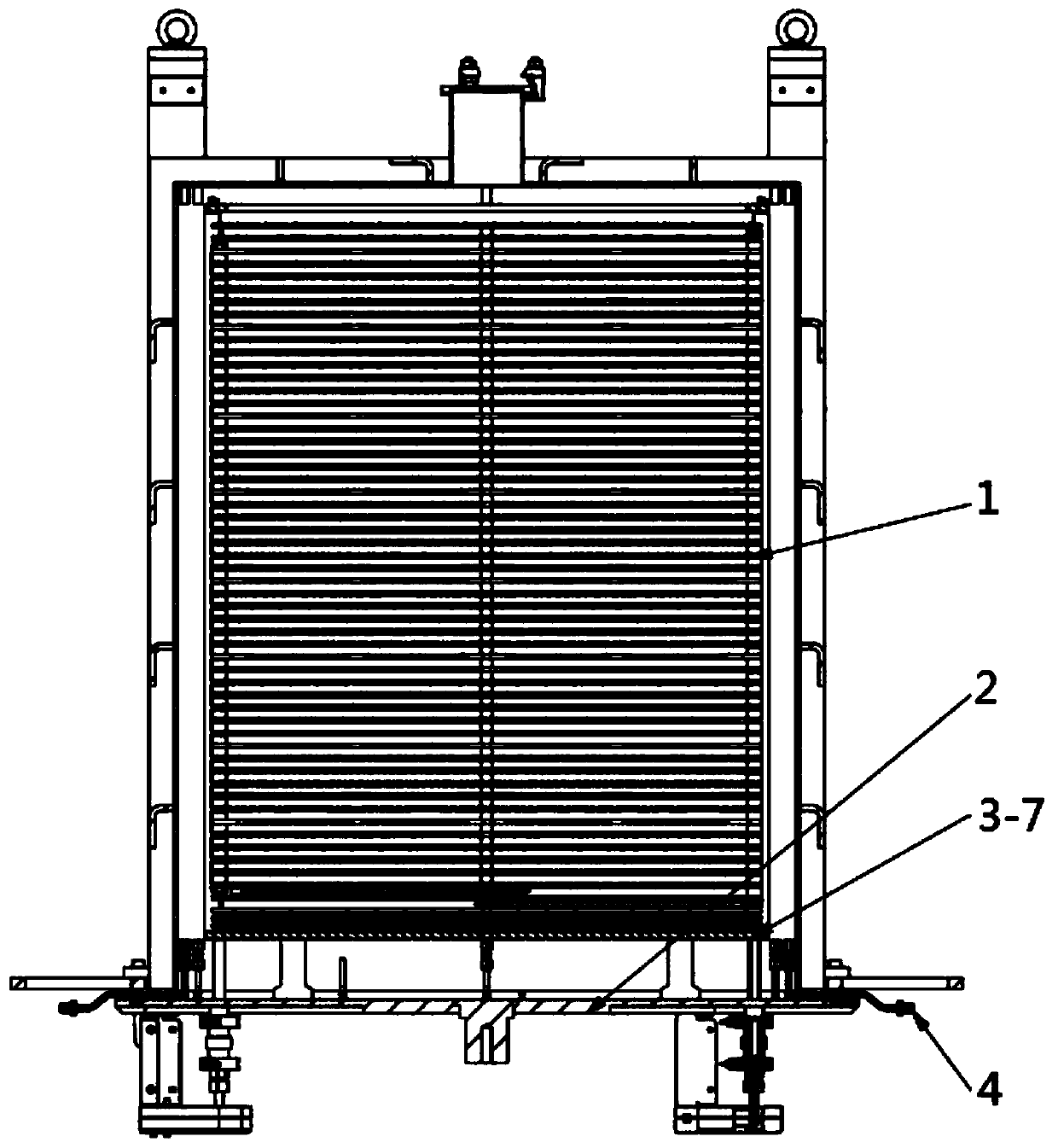

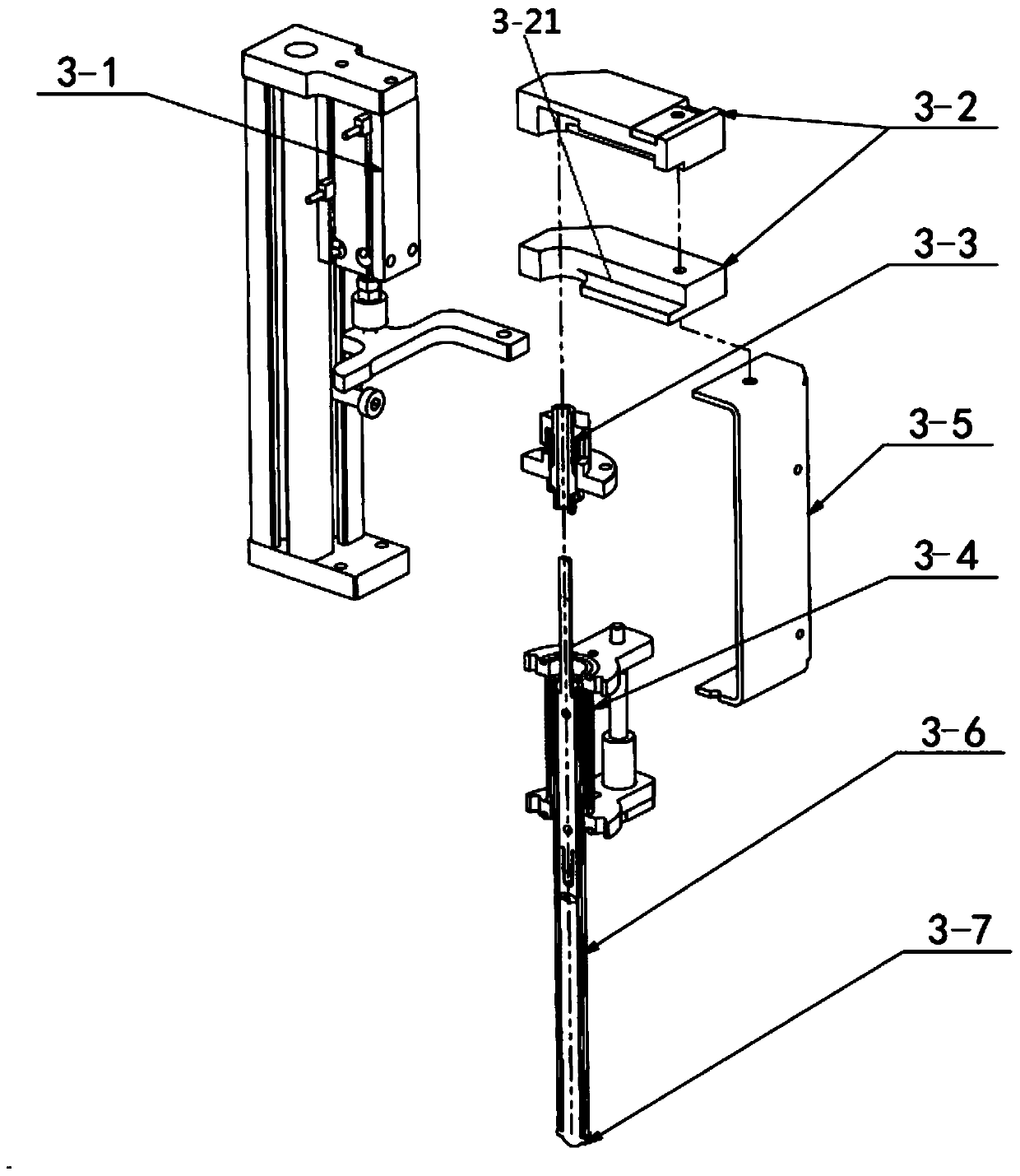

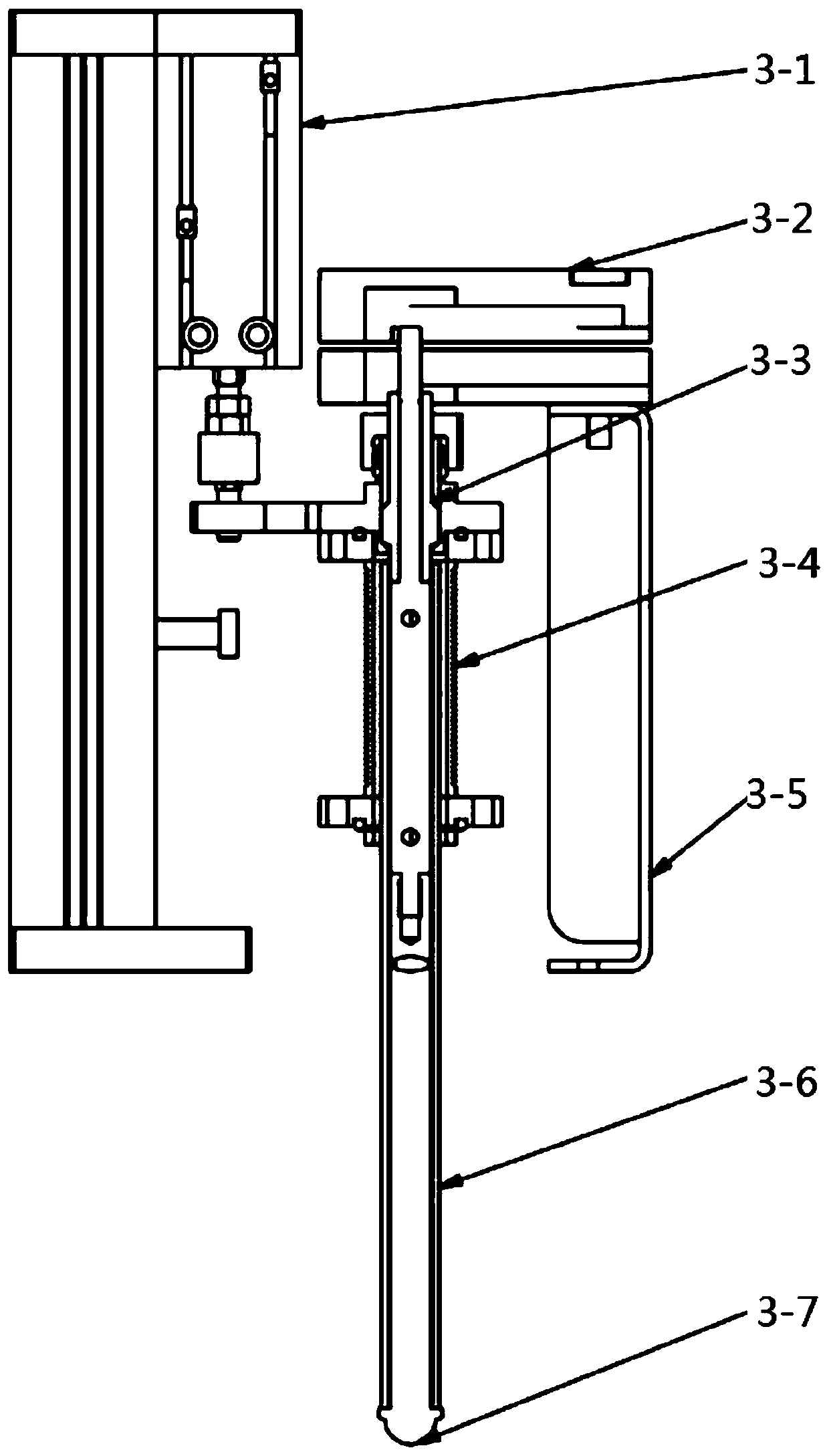

[0035] like Figure 1 to Figure 6 As shown, the semiconductor or photovoltaic material processing device includes an ark structure, a semiconductor or photovoltaic material processing structure; the ark structure is placed on the semiconductor or photovoltaic material processing structure, the electrode structure of the semiconductor or photovoltaic material processing structure and the first The two electrode columns 10 are connected; the processing equipment of semiconductor or photovoltaic materials includes a furnace body 1, a furnace door 2, and an electrode structure is arranged on the furnace door 2, and the electrode structure includes a first electrode column 3-7, an electrode body 3-5 and Insulation Materials. The first electrode column 3-7 is connected to the electrode body 3-5, and the insulating material covers the side of the first electrode column 3-7. By insulating and covering the electrode columns, only the two ends of the first electrode columns 3-7 are exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com