Plasma spraying device based on micro-cavity metal wire electrical explosion

A plasma and metal wire technology, applied in the direction of plasma and electrical components, can solve the problems of limiting the ability to conduct gas switches, limited conductivity and spray height, low conductivity, etc., to reduce the trigger voltage and ensure reliable leakage. flow, reducing the effect of burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

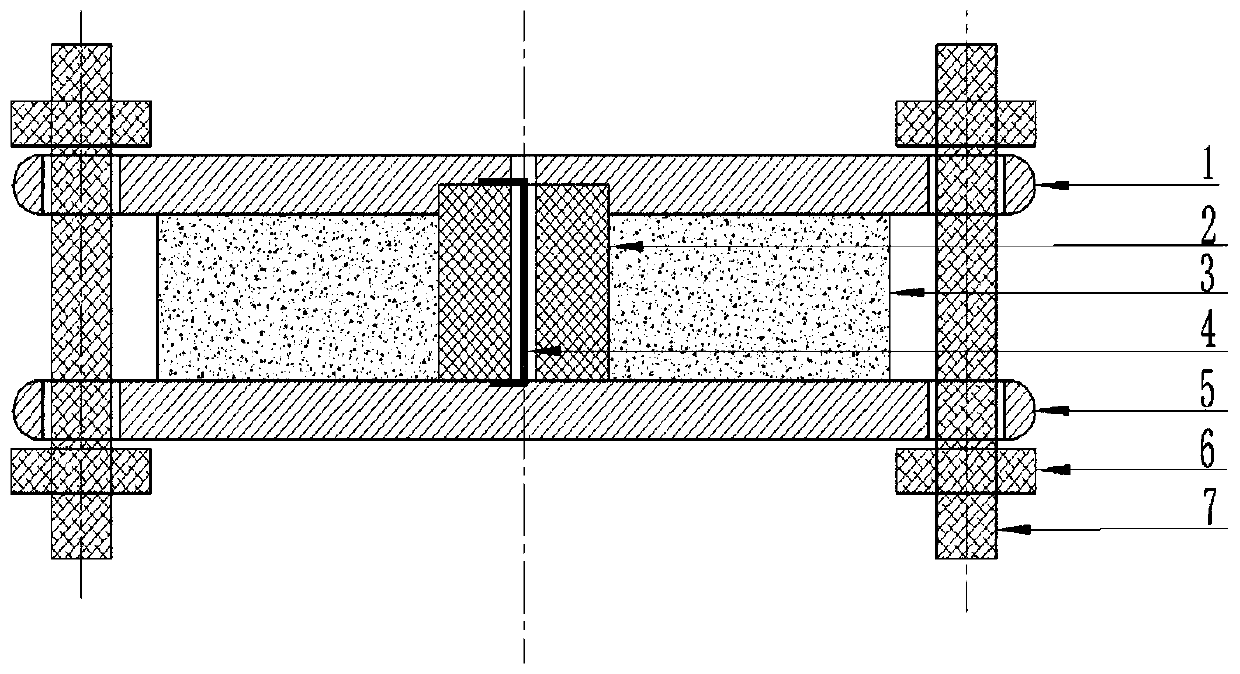

[0033] Attached below Figure 1 to Figure 3 The technical scheme of the present disclosure is described in detail with the examples.

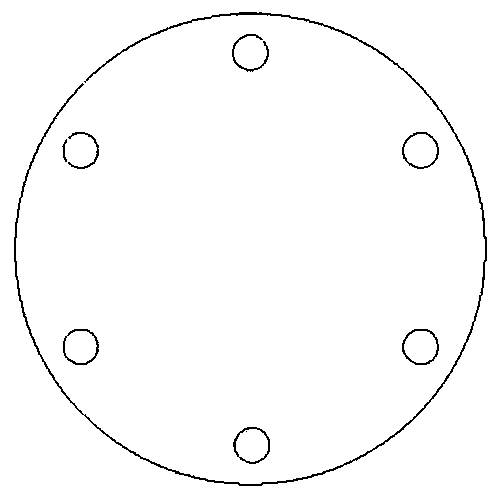

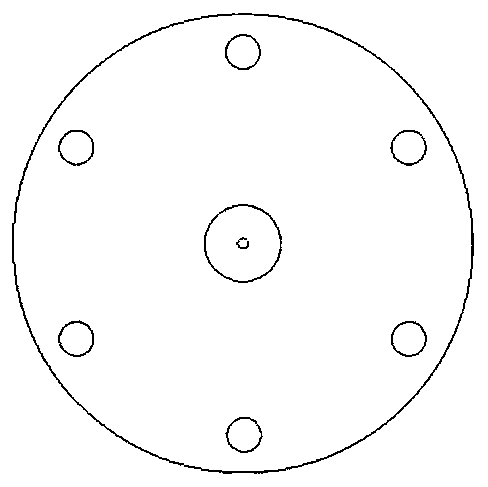

[0034] In one embodiment, such as figure 1 As shown, the present disclosure provides a plasma injection device based on microcavity metal wire electric explosion, including: a ground electrode 1, a wire explosion chamber 2 and a trigger electrode 5; wherein, the wire explosion chamber 2 is located at the ground electrode 1 and between the trigger electrode 5; the center of the surface of the ground electrode 1 is provided with a cylindrical groove, and the wire explosion cavity 2 is fixed with the ground electrode 1 through the cylindrical groove, and the wire explosion cavity 2 is fixed. A cylindrical microcavity is formed, and the microcavity communicates with the through hole arranged at the center of the cylindrical groove; a metal wire 4 is arranged in the microcavity, and the two ends of the metal wire 4 are connected to the ground elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com