High-efficiency plasma synthetic jet exciter based on steam pressure enhancement

A plasma and synthetic jet technology, applied in the direction of plasma, electrical components, etc., can solve the problems of low energy conversion efficiency, insufficient air backfill, misfire" and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

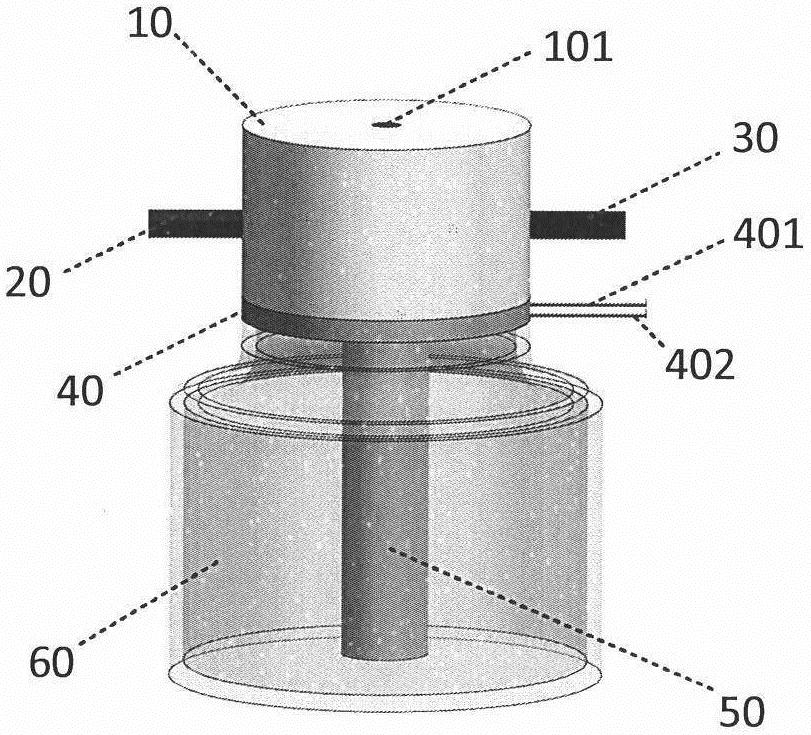

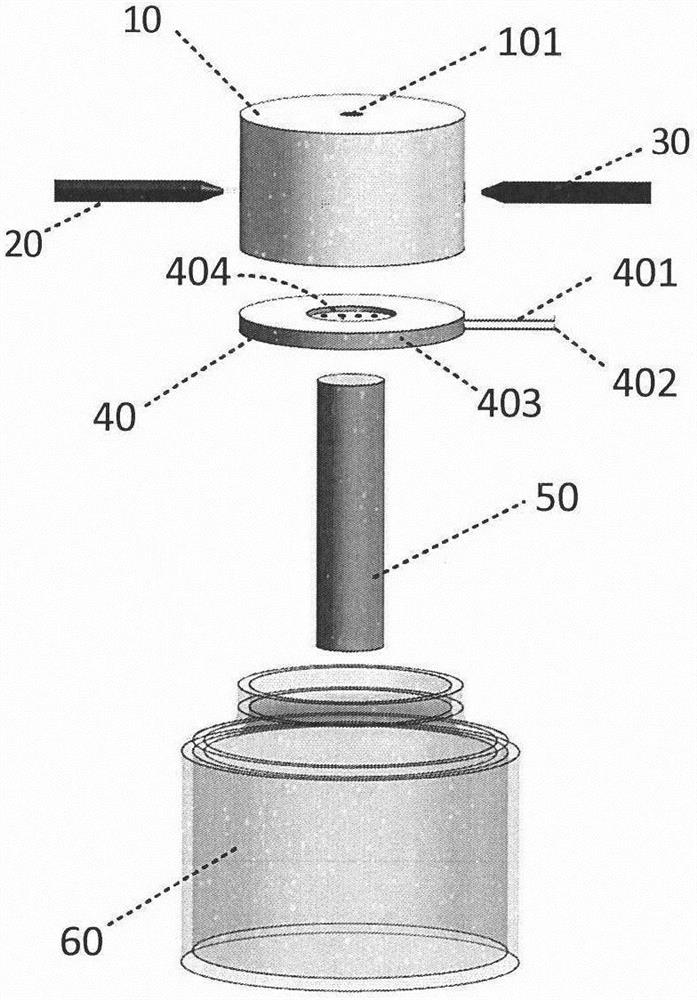

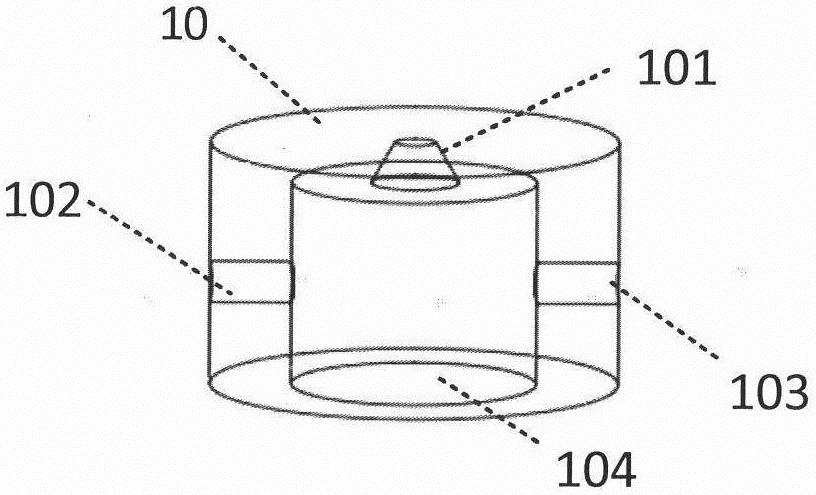

[0026] Figure 1-3They are the combined schematic diagram, the exploded diagram and the structural schematic diagram of the insulating shell of the high-efficiency plasma synthetic jet exciter with enhanced vapor pressure of the present invention. The exciter is mainly composed of six parts: an insulating shell 10 , a ground electrode 20 , a high-voltage electrode 30 , an ultrasonic atomizing sheet 40 , a cotton swab 50 and a water storage tank 60 . The insulating casing 10 is a hollow cylinder with an upper surface but no lower surface, and the inside of the hollow cylinder is a discharge chamber 104 . The outer diameter of the insulating housing 10 is 10-20mm, preferably 15mm; the height is 10-15mm, preferably 12mm. Considering that the internal working temperature of the exciter may be close to 1000K when the exciter works for a long time and high frequency, the material of the insulating housing 10 is preferably a high temperature resistant ceramic material such as alumin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com