Production method of low-haze vacuum evaporation coating

A production method and technology of evaporated film, applied in applications, coatings, household appliances, etc., can solve the problems of reduced density of metal layers, negative quality of consumer products, inconsistent refractive index of films, etc., to achieve reduced haze and better perspective Effect and appearance effect, effect of wide adjustment range of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

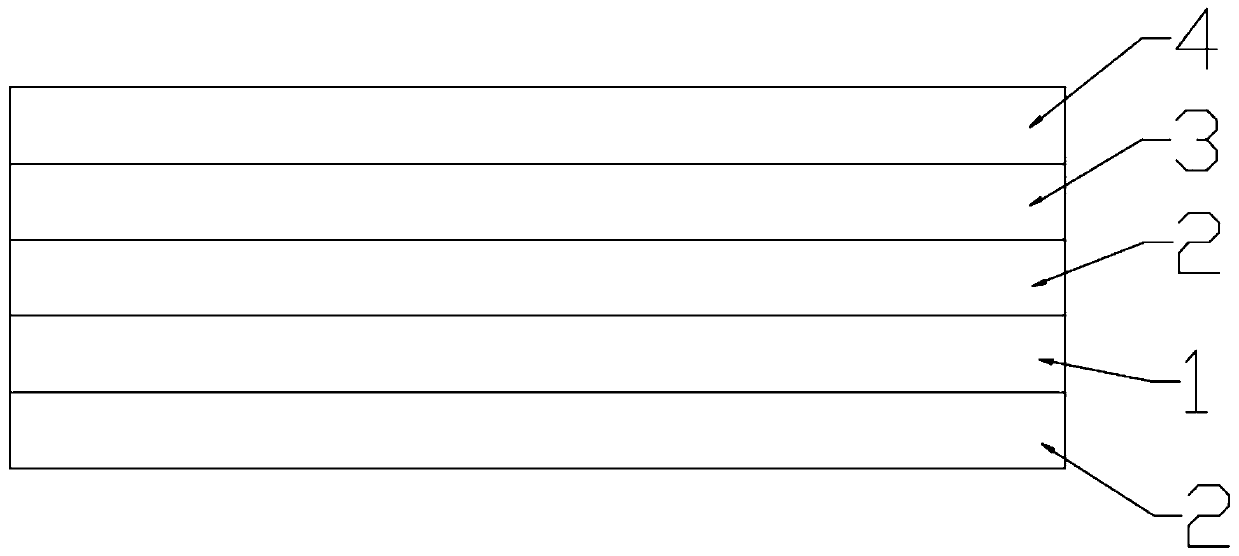

Image

Examples

Embodiment 1

[0043] A method for producing a low-haze vacuum-evaporated film, the process of which mainly includes:

[0044] S1. Resin conveying and mixing: Add the anti-blocking masterbatch containing 90% of the plastic component and 10% of the anti-blocking agent component into the material mixer of the auxiliary extruder for mixing first, and then transport it to the auxiliary extruder In the hopper of the extruder, 100% plastic particles are added to the hopper of the main extruder;

[0045] S2. Melt extrusion: twin-screw extruder is used for melt extrusion, the length-to-diameter ratio of the extruder is: L / D=30, divided into feeding section / compression section / metering section, and the temperature distribution of each section is: main extrusion The temperature of the extruder is: 280, 280, 279, 279, 280, 280, 280, the temperature of the auxiliary extruder is: 280, 279, 277, 276, 276, 277, 278, through the melt pipe and the static mixer The melt is extruded from the long slit die, an...

Embodiment 2

[0061] The difference between this example and Example 1 is that in step S4, the curing agent is hexamethylene-1,6 diisocyanate.

Embodiment 3

[0063] The difference between this example and Example 1 is that in step S4, the curing agent is diphenylmethylene diisocyanate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com