Silicon-based quadrangular frustum pyramid-shaped micro through hole array, preparation method and application thereof

A quadrangular pyramid-shaped, miniature technology, applied in the field of material processing, can solve the problems of accumulated errors and low efficiency, and achieve the effects of high processing efficiency, precise and controllable relative position and hole shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

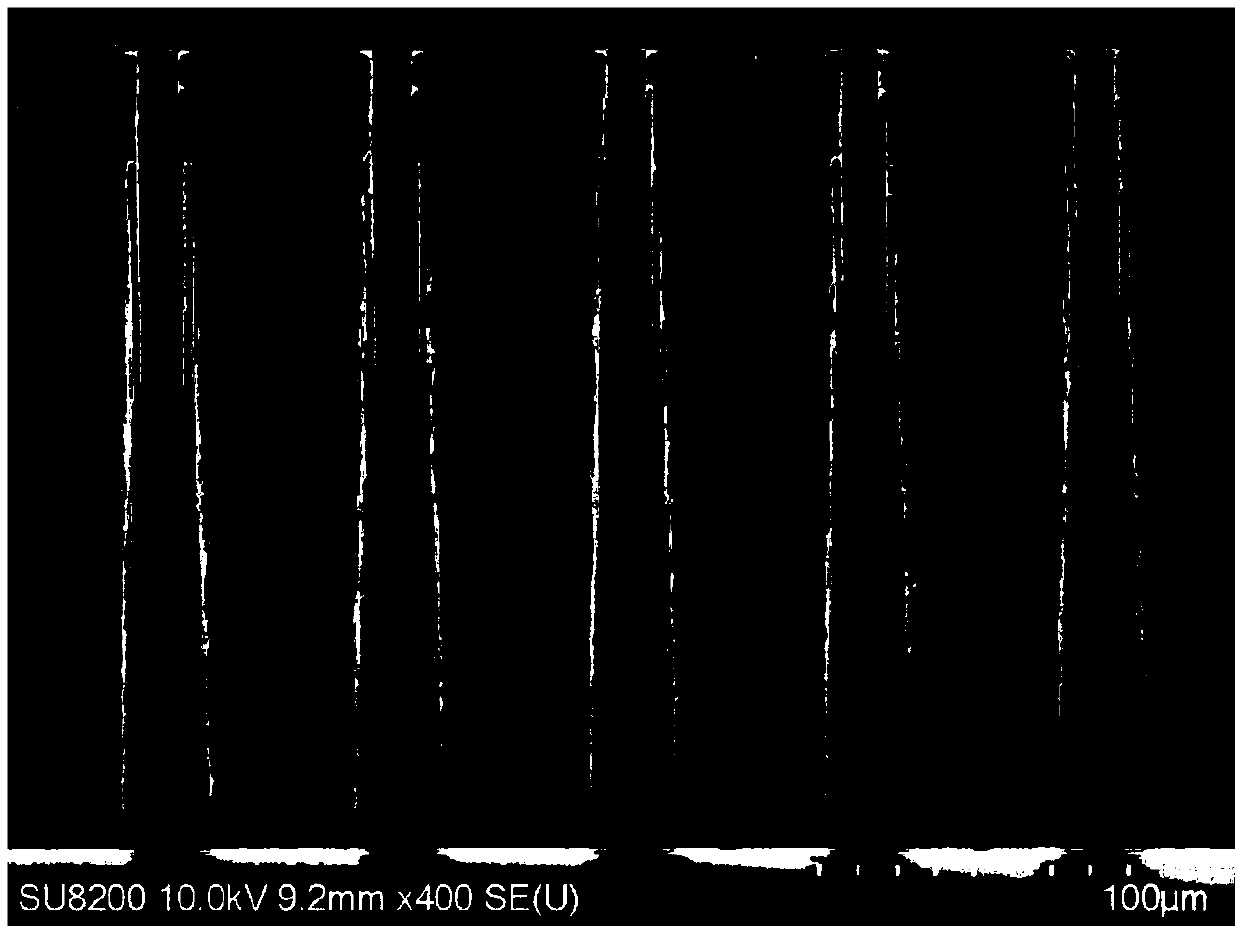

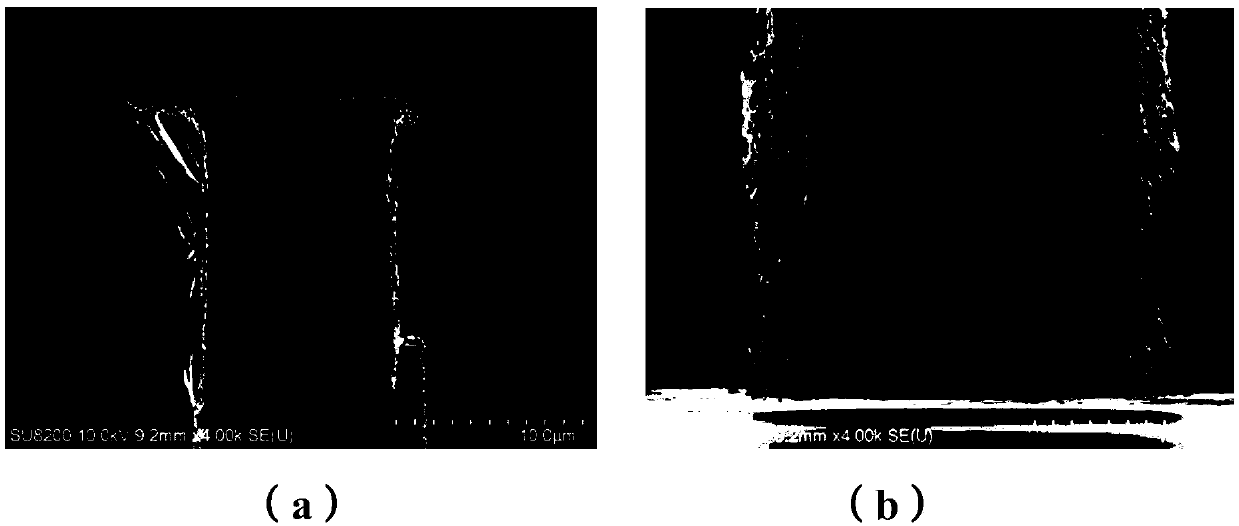

[0068] This embodiment is used to illustrate the preparation method of the tetragonal truss micro-via array of the present invention.

[0069] (1) Make the mask plate Use AutoCAD software to draw the required graphics array, and then send the file to Shenzhen Meijing Micro Optoelectronics Co., Ltd., which will make the mask plate.

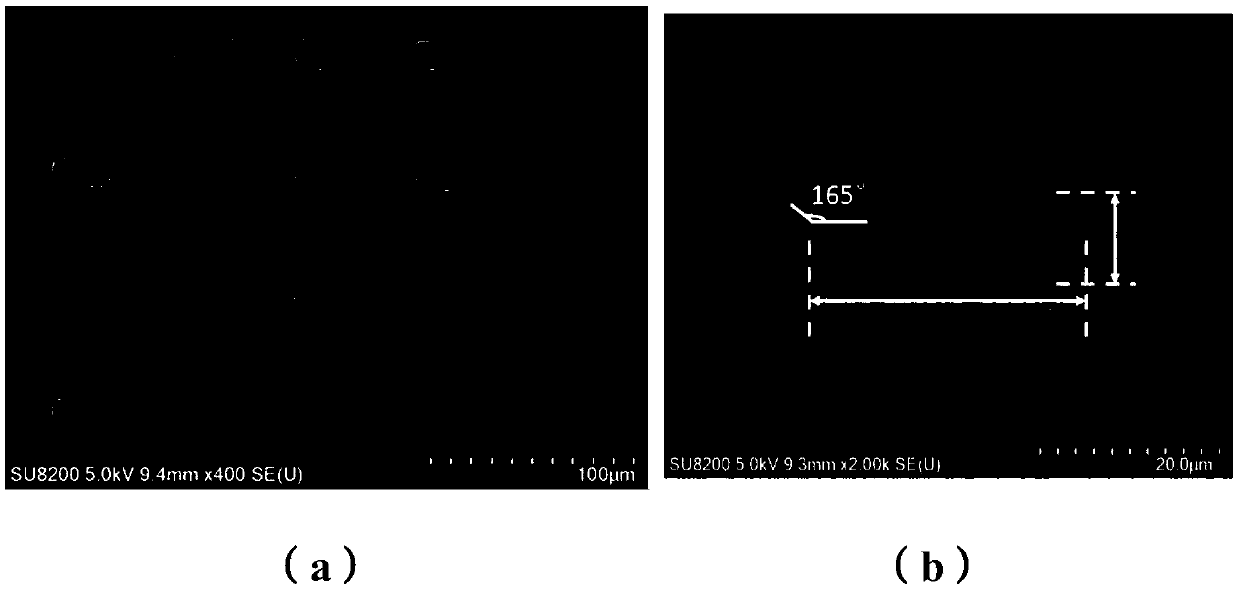

[0070] The mask plate produced is a five-inch chrome plate, the graphic array is a rectangle, the length of the rectangle is 30 μm, the width is 8 μm, the distance between each two rectangles is 60 μm, and 10,000 rectangles are distributed in an area of 14mm×14mm, each There are 24 rectangular arrays spread across the chrome board.

[0071] (2) Choose a double-sided polished silicon wafer substrate

[0072] The type of silicon wafer is N-type, the crystal orientation is (100), the dopant is phosphorus, the diameter is 100 mm, and the thickness is 200 μm.

[0073] (3) One side of the silicon wafer is coated with glue, exposed and developed

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com