Composting material for increasing survival rate of tobacco plant seedlings and processing method thereof

A technology for composting materials and processing methods, applied in the field of composting materials, can solve the problems of inability to improve the survival rate of tobacco seedlings, low survival rate of tobacco seedlings, and no tobacco seedlings, etc. The effect of survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

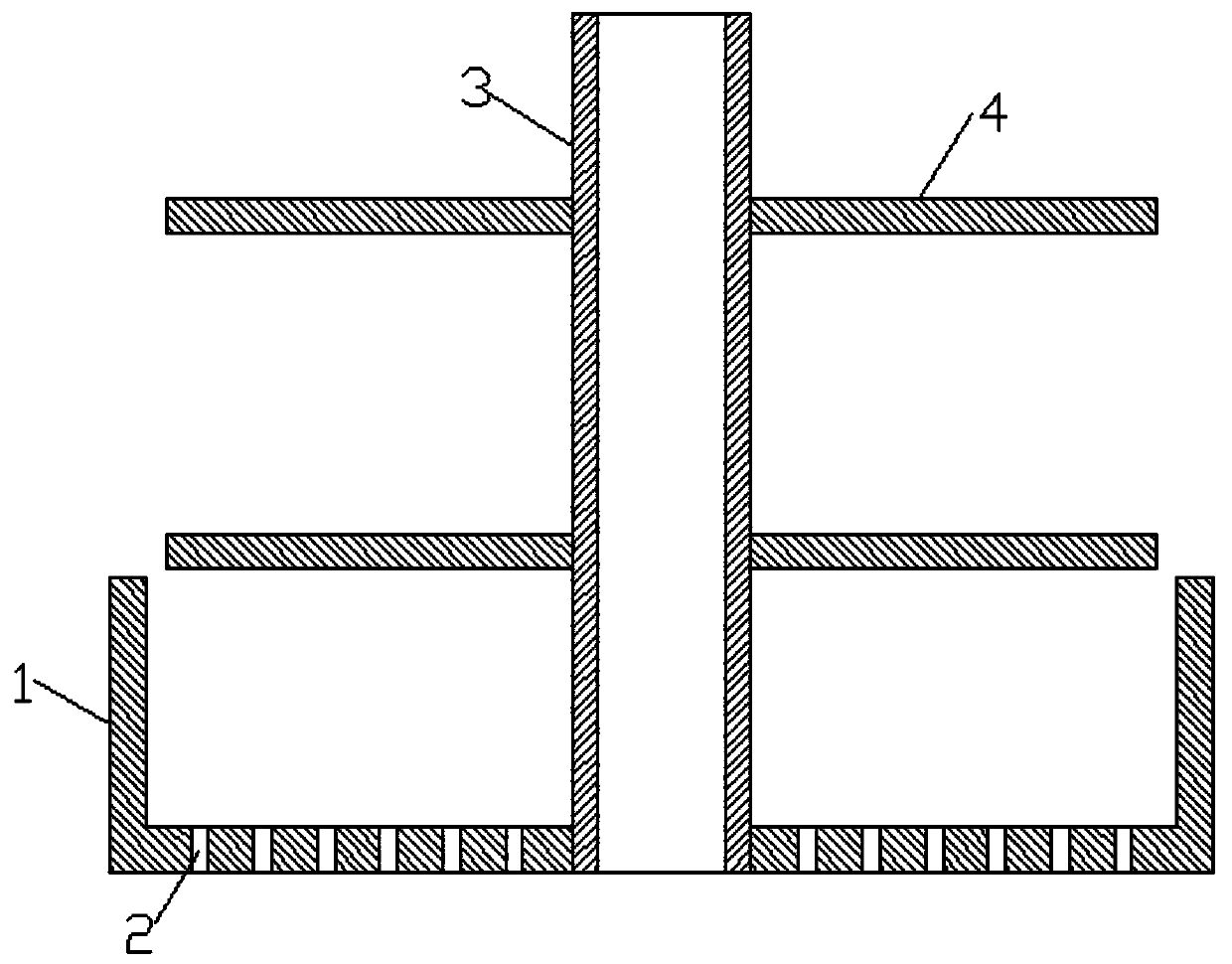

Image

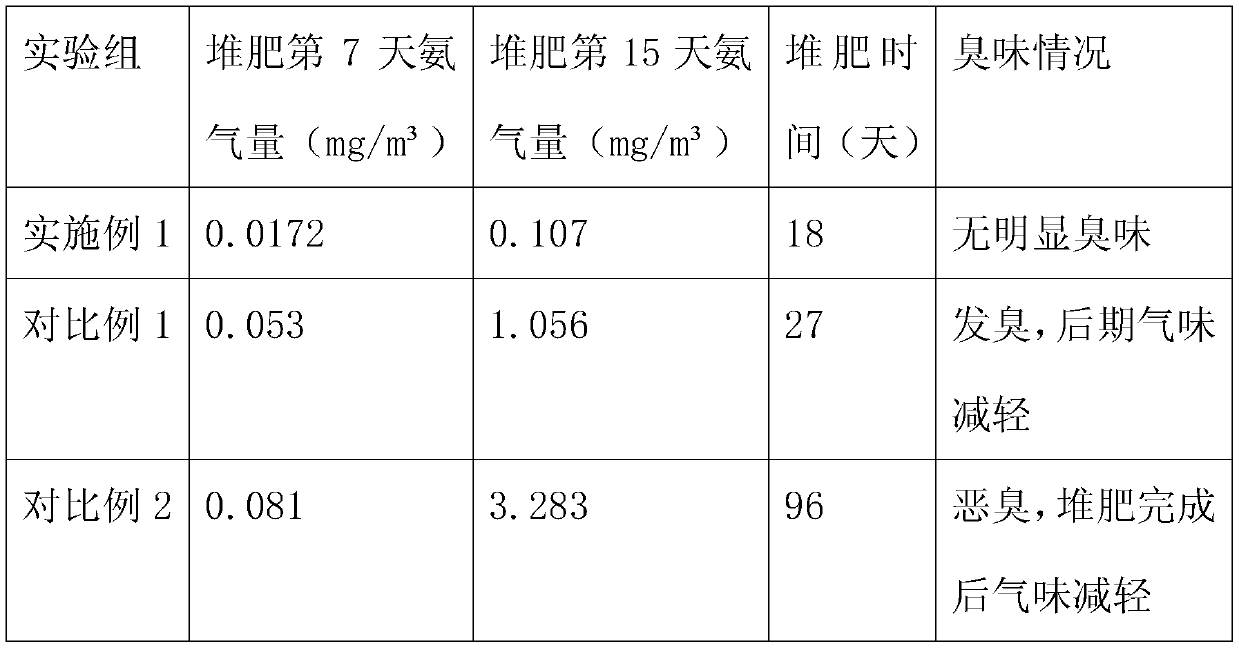

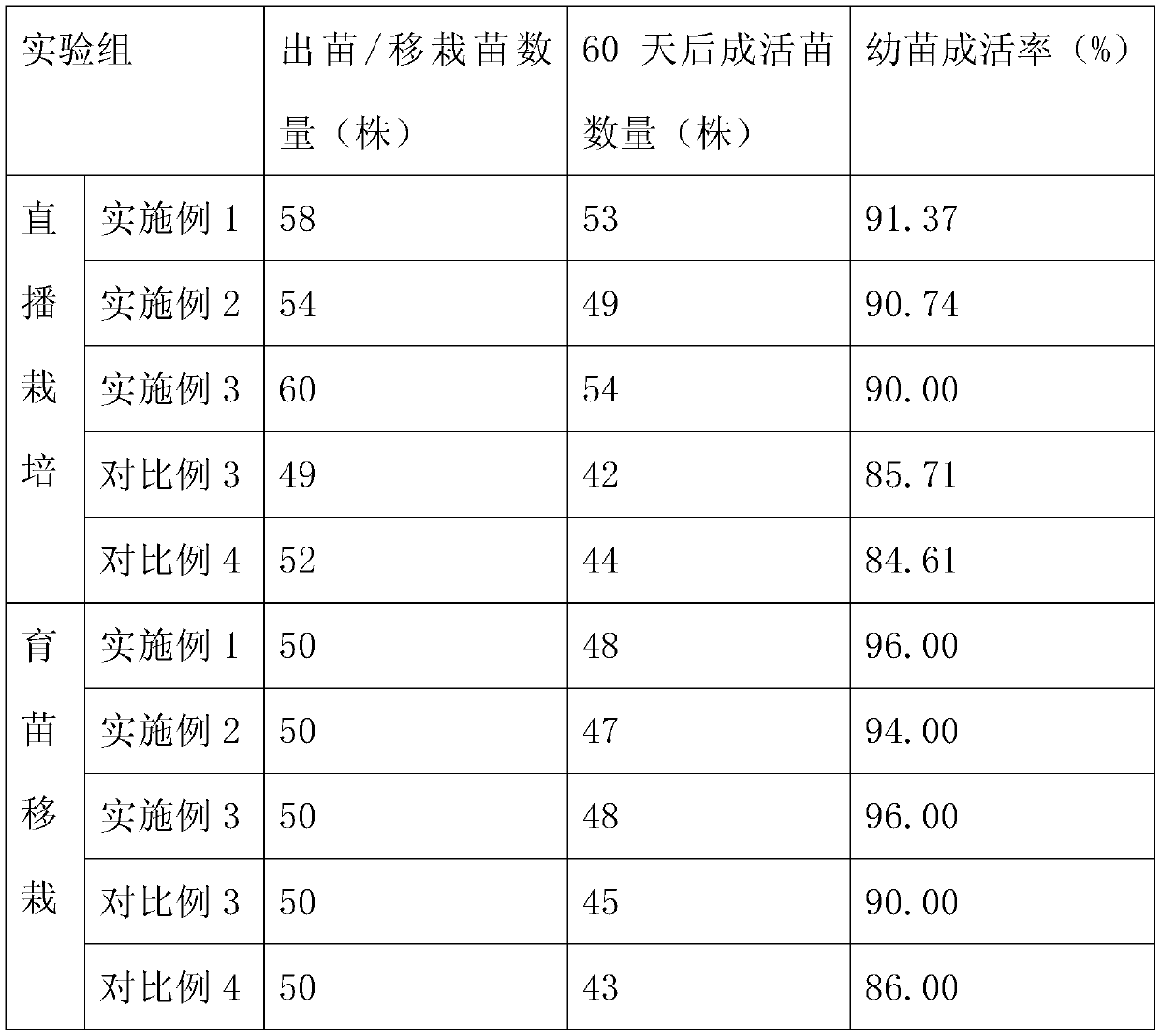

Examples

Embodiment 1

[0026] A compost material for improving the survival rate of tobacco plant seedlings, comprising the following components in parts by weight: 40 parts of straw, 13 parts of peat, 6 parts of expanded perlite, 30 parts of poultry manure, 15 parts of mushroom dregs, and 5 parts of coix seed dregs 7 parts of alfalfa leaves; the alfalfa leaves are dry leaves with a water content of 10-15%; poultry manure is chicken manure.

[0027] A method for processing compost materials for improving the survival rate of tobacco plant seedlings, comprising the following steps:

[0028] (1) Take straws with 90% of the total mass of straws and crush them into 3-5cm straw particles, wind the remaining straws every 3-4 into fluffy ropes to obtain straw ropes, mix alfalfa leaves with mushroom slag and coix seed The dregs are mixed evenly to obtain a mixture;

[0029] (2) Pack poultry and livestock manure into the plant fiber packaging bag, close the mouth of the bag, and obtain the manure bag;

[0...

Embodiment 2

[0041] A compost material for improving the survival rate of tobacco plant seedlings, comprising the following components in parts by weight: 30 parts of straw, 11 parts of peat, 5 parts of expanded perlite, 20 parts of poultry manure, 13 parts of mushroom dregs, and 3 parts of raw coix seed dregs 5 parts of alfalfa leaves and 0.1 part of plant fiber packaging bag; the alfalfa leaves are dry leaves with a water content of 10-15%; poultry manure is chicken manure. The processing method of compost material is identical with embodiment 1.

Embodiment 3

[0043] A compost material for improving the survival rate of tobacco plant seedlings, comprising the following components in parts by weight: 50 parts of straw, 15 parts of peat, 8 parts of expanded perlite, 40 parts of poultry manure, 16 parts of mushroom dregs, and 7 parts of raw coix seed dregs parts, 10 parts of alfalfa leaves, and 0.3 parts of plant fiber packaging bag; the alfalfa leaves are dry leaves with a water content of 10-15%; poultry manure is chicken manure. The processing method of compost material is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com