Low-density flexible high-thermal-conductivity wave-absorbing silica gel sheet, and preparation method and equipment thereof

A technology with high thermal conductivity and low density, applied in chemical instruments and methods, heat exchange materials, other chemical processes, etc., can solve the inaccurate detection of physical and chemical properties of silica gel sheets, the inaccurate control of material quality and performance, and the proportion To achieve the effect of speeding up production efficiency and quality, simplifying equipment and process steps, and simplifying production process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

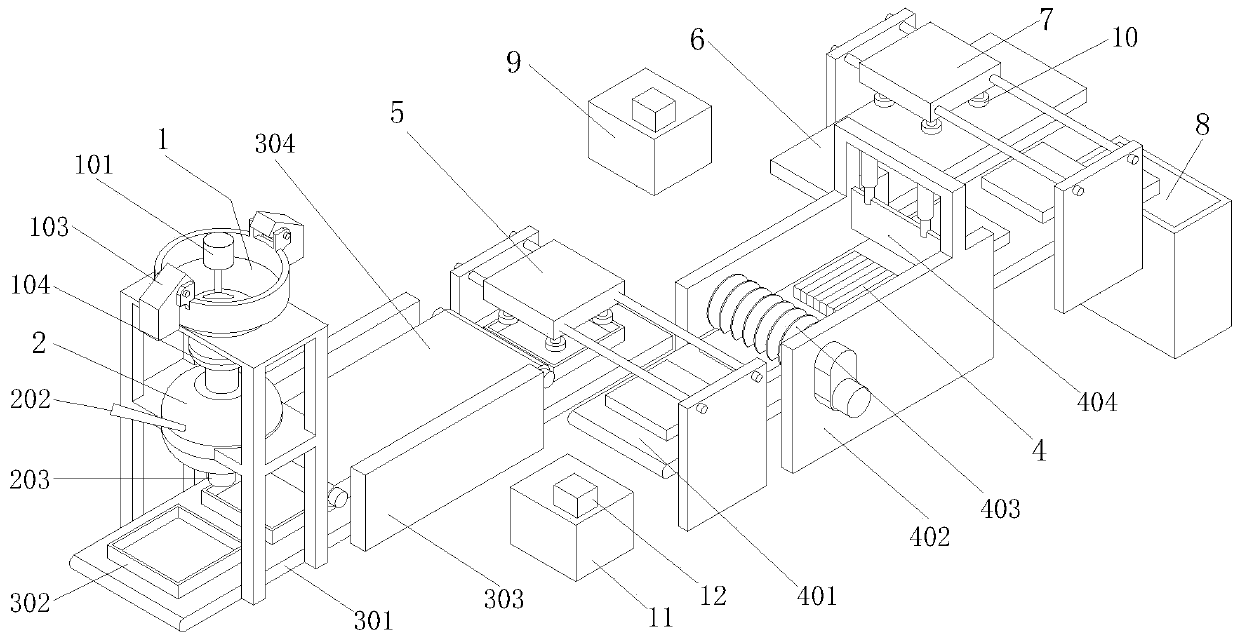

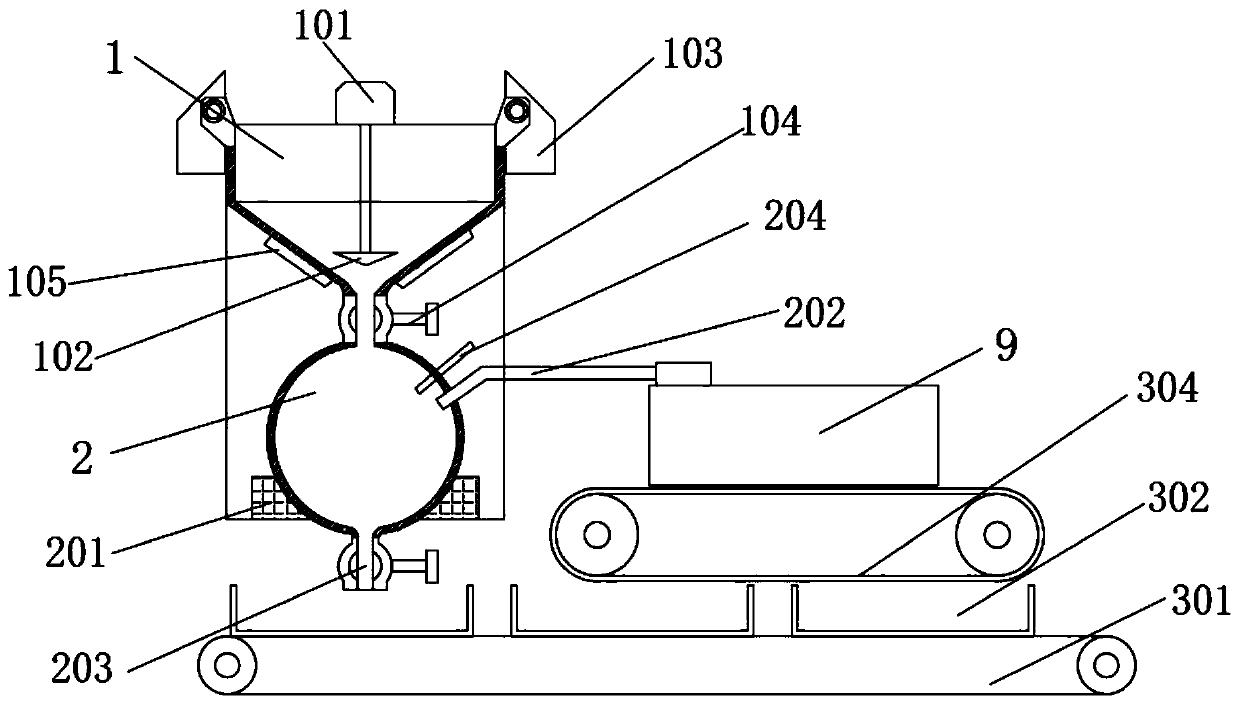

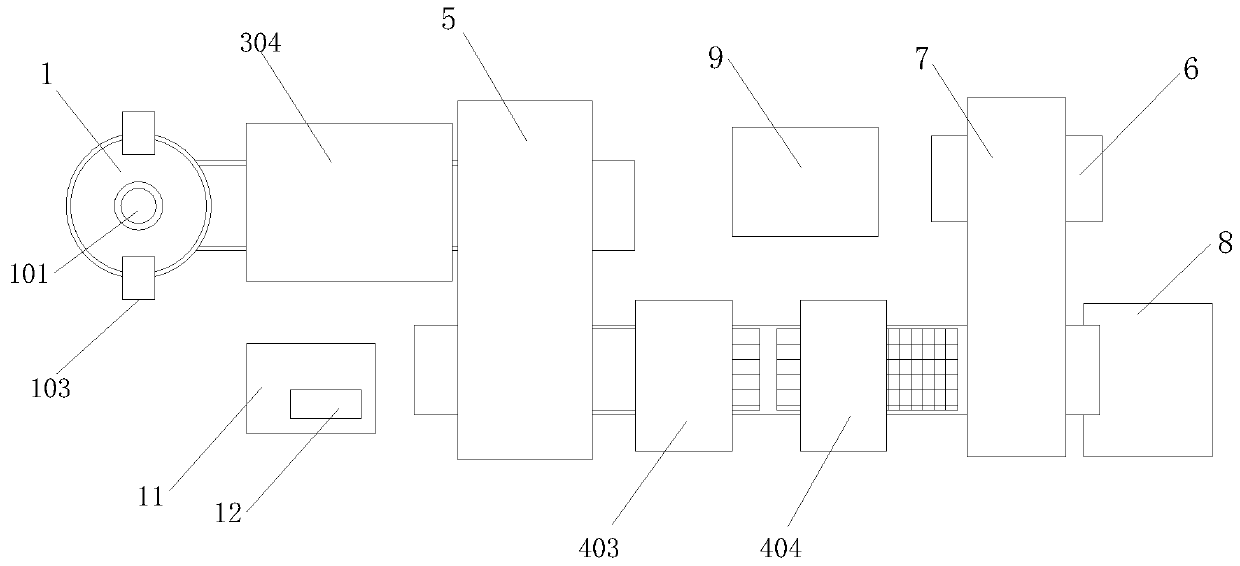

[0036] see Figure 1-4 , the low-density flexible high-thermal conductivity wave-absorbing silica gel sheet provided by the embodiment of the present invention is prepared from the following components in parts by weight:

[0037] Vinyl silicone oil: 100 parts; silicone resin: 10-30 parts; raw rubber: 60-80 parts; crosslinking agent: 5-10 parts; low-density filler: 1000-1500 parts; Oxygen-coated hollow glass microspheres are 75-95 parts, magnetic multilayer carbon nanotubes are 5-25 parts; catalyst: 0.1-0.5; inhibitor: 0.1-0.2.

[0038] In this embodiment, it is specifically prepared from the following components by weight:

[0039] Vinyl silicone oil: 100; silicone resin: 15; raw rubber: 70; crosslinking agent: 8; Beryllium 300; wave-absorbing filler: 90 parts, including: barium ferrite-coated hollow glass microspheres 80 parts, magnetic multilayer carbon nanotubes 20 parts; catalyst: 0.4; inhibitor: 0.15.

[0040] The cross-linking agent is one of bis-2-4, 2-2-5, hydrogen...

Embodiment 2

[0066] The low-density flexible high-thermal conductivity wave-absorbing silica gel sheet, preparation method and equipment provided in this example are basically the same as those in Example 1, except that:

[0067] In this embodiment, the low-density flexible high-thermal-conductivity wave-absorbing silica gel sheet is specifically prepared from the following components by weight:

[0068] Vinyl silicone oil: 100; silicone resin: 10; raw rubber: 60; crosslinking agent: 5; Beryllium 100; wave-absorbing filler: 80 parts, including: 75 parts of barium ferrite-coated hollow glass microspheres, 5 parts of magnetic multilayer carbon nanotubes; catalyst: 0.1; inhibitor: 0.1.

Embodiment 3

[0070] The low-density flexible high-thermal conductivity wave-absorbing silica gel sheet, preparation method and equipment provided in this example are basically the same as those in Examples 1 and 2, except that:

[0071] In this embodiment, the low-density flexible high-thermal-conductivity wave-absorbing silica gel sheet is specifically prepared from the following components by weight:

[0072] Vinyl silicone oil: 100; silicone resin: 30; raw rubber: 80; crosslinking agent: 10; Beryllium 200; wave-absorbing filler: 100 parts, including: 95 parts of barium ferrite-coated hollow glass microspheres, 5 parts of magnetic multilayer carbon nanotubes; catalyst: 0.1; inhibitor: 0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com