Horizontal connecting structure for assembled wall

A connection structure and assembly technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor stability and difficult splicing, and achieve the effect of reducing the use of bolts, facilitating splicing, and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

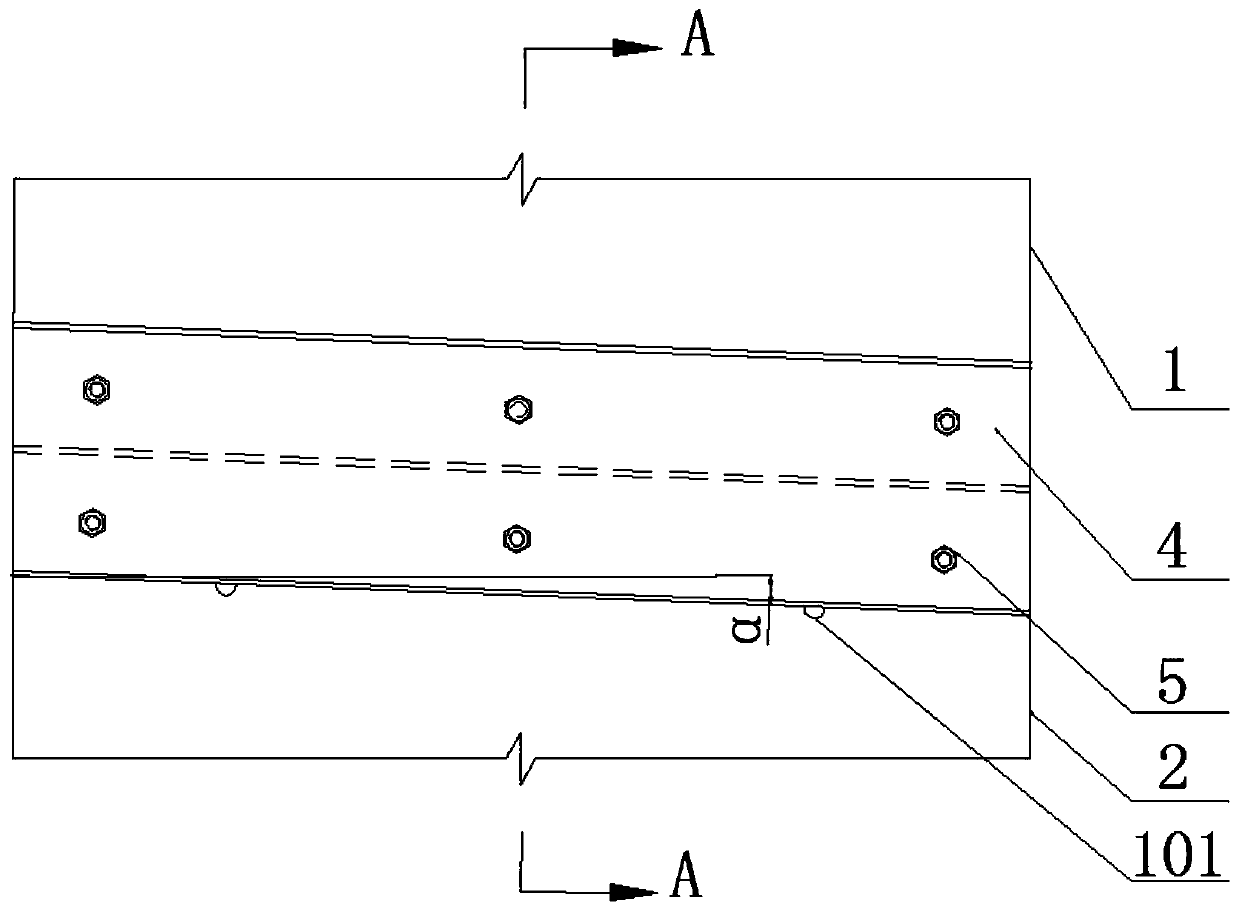

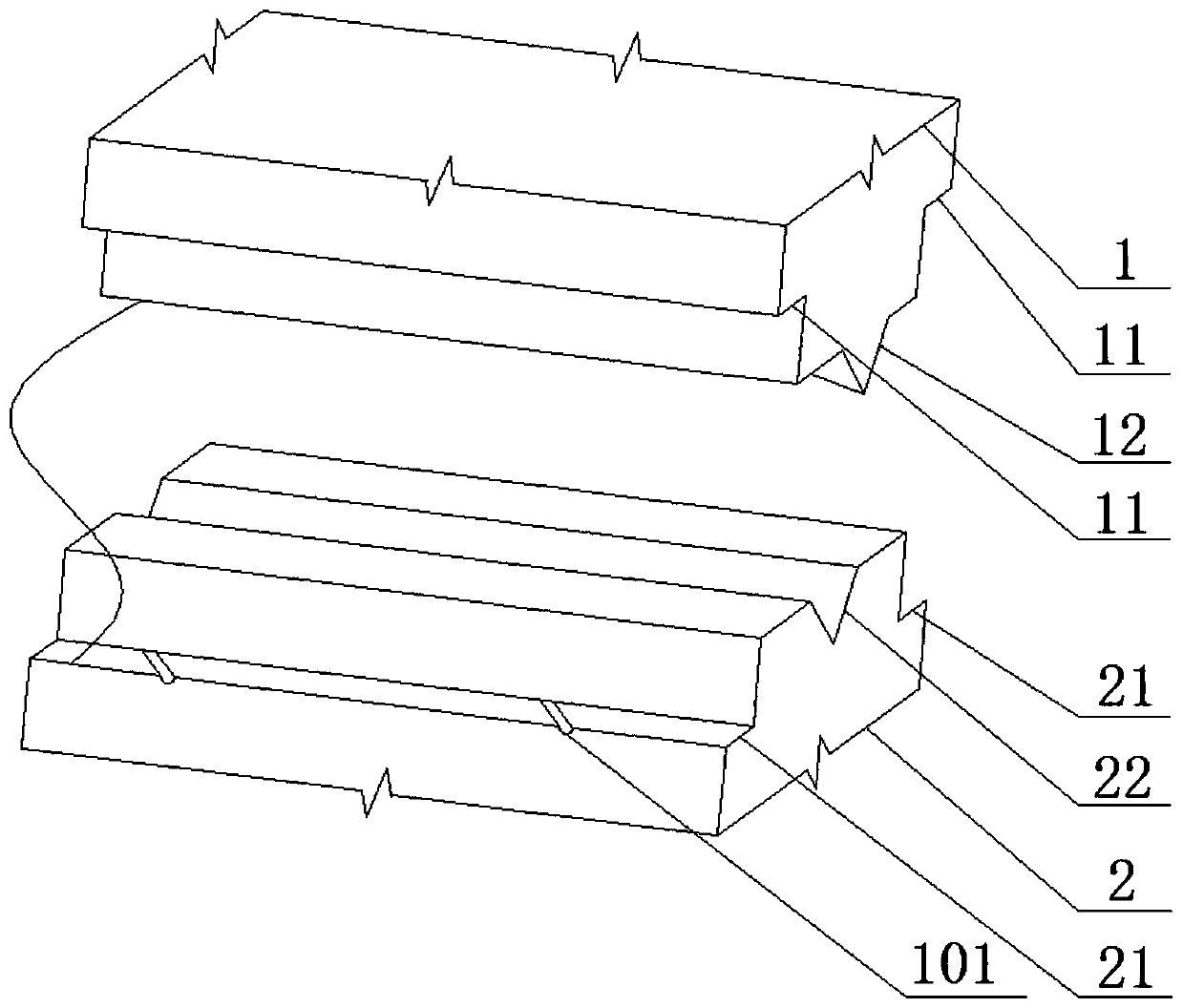

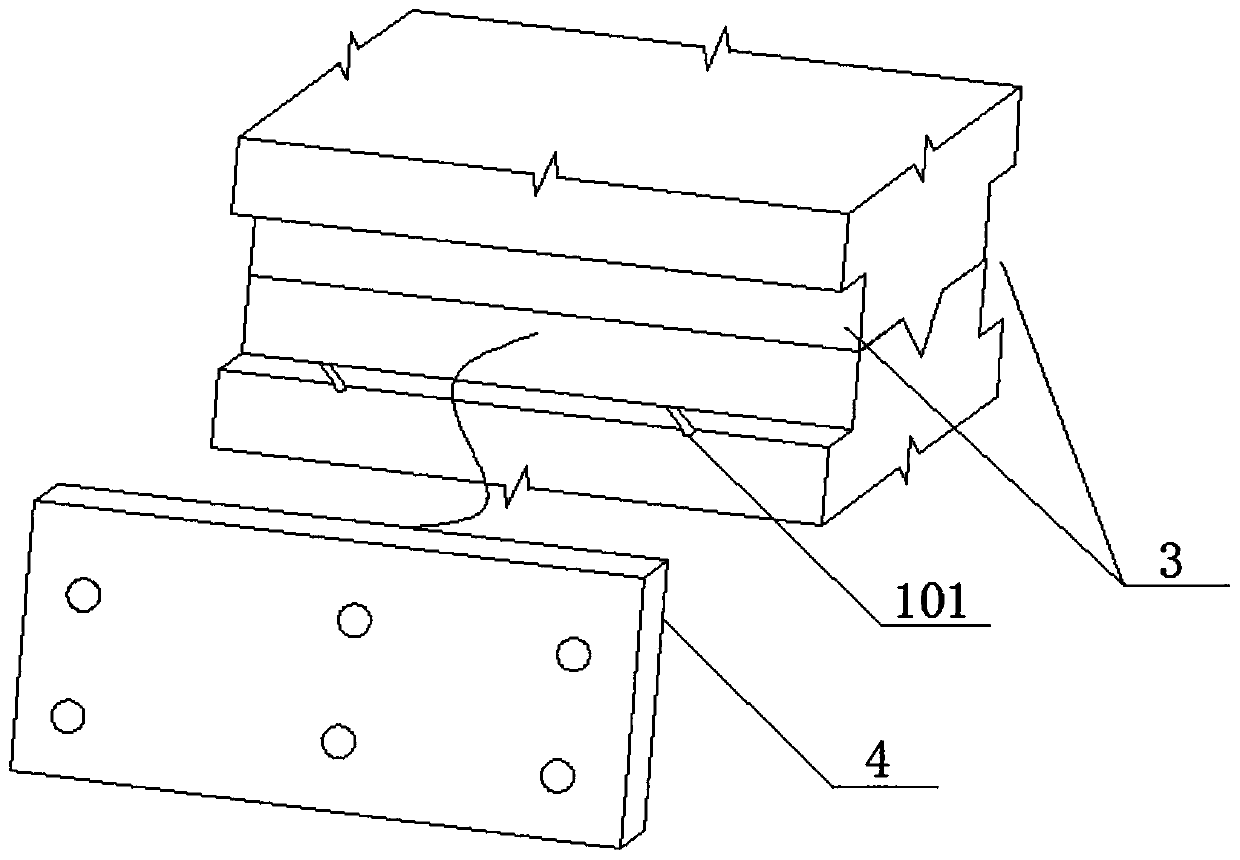

[0030] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the horizontal connection structure for the assembled wall of the present invention includes a wall, and the wall includes a first wall 1 and a second wall 2 connected to each other in the vertical direction, and the first wall 1 First steps 11 are provided on both sides of the second wall 2, and second steps 21 are provided on both sides of the second wall 2, and the first steps 11 and the second steps 21 are enclosed to form a through groove 3; The connecting piece 4 inside the slot 3 and matched with the slot 3 is a metal plate structure; the connecting piece 4 is connected to the first wall 1 and the second wall 2 through bolts 5 respectively. The bolts 5 sequentially pass through the first step on one side, the wall and the first step on the other side to connect with the nuts 6 . The first step 11 is provided with a drainage groove 101 ; the bottom of the through groove 3 is provided with a waterp...

Embodiment 2

[0033] This embodiment is a further improvement made on the basis of the first embodiment. Such as figure 2 , image 3 and Figure 4 As shown, the side of the first wall 1 connected to the second wall 2 is provided with a protruding post 12 , and the second wall 2 is provided with a slide groove 22 matching the protruding post 12 at a corresponding position.

[0034] Working principle: The structure of the convex column plays a certain role in waterproofing, preventing water from entering the joint of the wall; When splicing between walls, the convex column can slide in the chute, so as to avoid misalignment between walls.

Embodiment 3

[0036] This embodiment is a further improvement made on the basis of the second embodiment. Such as figure 2 , image 3 and Figure 4 As shown, the slide groove 22 is a tapered groove, and the width of the tapered groove gradually decreases in the direction away from the first wall 1 .

[0037] Working principle: Since the tapered groove is wide at the top and narrow at the bottom, when splicing between the walls, the tapered groove first limits the position of the convex column to avoid misalignment and horizontal rotation between the walls; Therefore, the tapered groove has a guiding effect on the convex post, and the convex post is automatically aligned with the tapered groove, thereby increasing the speed of splicing between walls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com