Optical fiber ring type residual stress test system and residual stress test method

A residual stress and testing system technology, which is applied in the direction of force measurement, measurement force, and measurement device by measuring the change of optical properties of materials when they are stressed, which can solve the problem of increasing the difficulty and complexity of the drilling method, and the inability to penetrate the material. The overall stress distribution test, inconvenient wiring of multiple resistance strain gauges, etc., can reduce the difficulty of connection, simple structure, and reduce errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

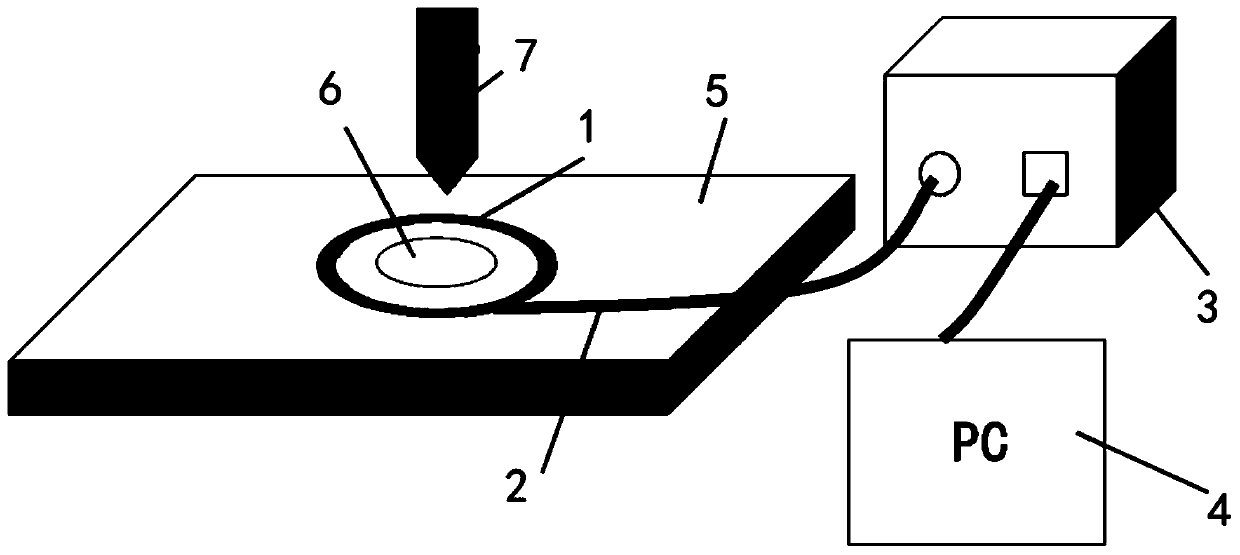

[0055] Such as figure 1 As shown, an optical fiber ring type residual stress testing system includes several optical fiber sensors, transmission optical fiber 2, demodulation device 3 and data processing device 4.

[0056] A number of optical fiber sensors are connected in series through the transmission optical fiber 2 and wound into a circle to form the optical fiber sensor ring 1. It can be realized by marking or making circular grooves of the same size. The optical fiber sensor ring 1 is fixed on the surface of the material 5 to be tested and connected to the demodulation device 3 through the transmission fiber 2 , and the demodulation device 3 is electrically connected with the data processing device 4 .

[0057] The fiber optic sensor is used to test the wavelength signal of the measuring point before and after drilling, and transmits the measured wavelength signal to the demodulation device 3 through the transmission fiber 2, and the demodulation device 3 is used to de...

Embodiment 2

[0066] This embodiment discloses a method for residual stress testing using the optical fiber ring type residual stress testing system of Embodiment 1, which specifically includes the following steps:

[0067] Step 1. Mark the center of the drilling hole at the center of the surface of the material 5 to be tested, and use this mark as the center of the fiber sensor ring 1 to set the installation position of the fiber sensor ring 1;

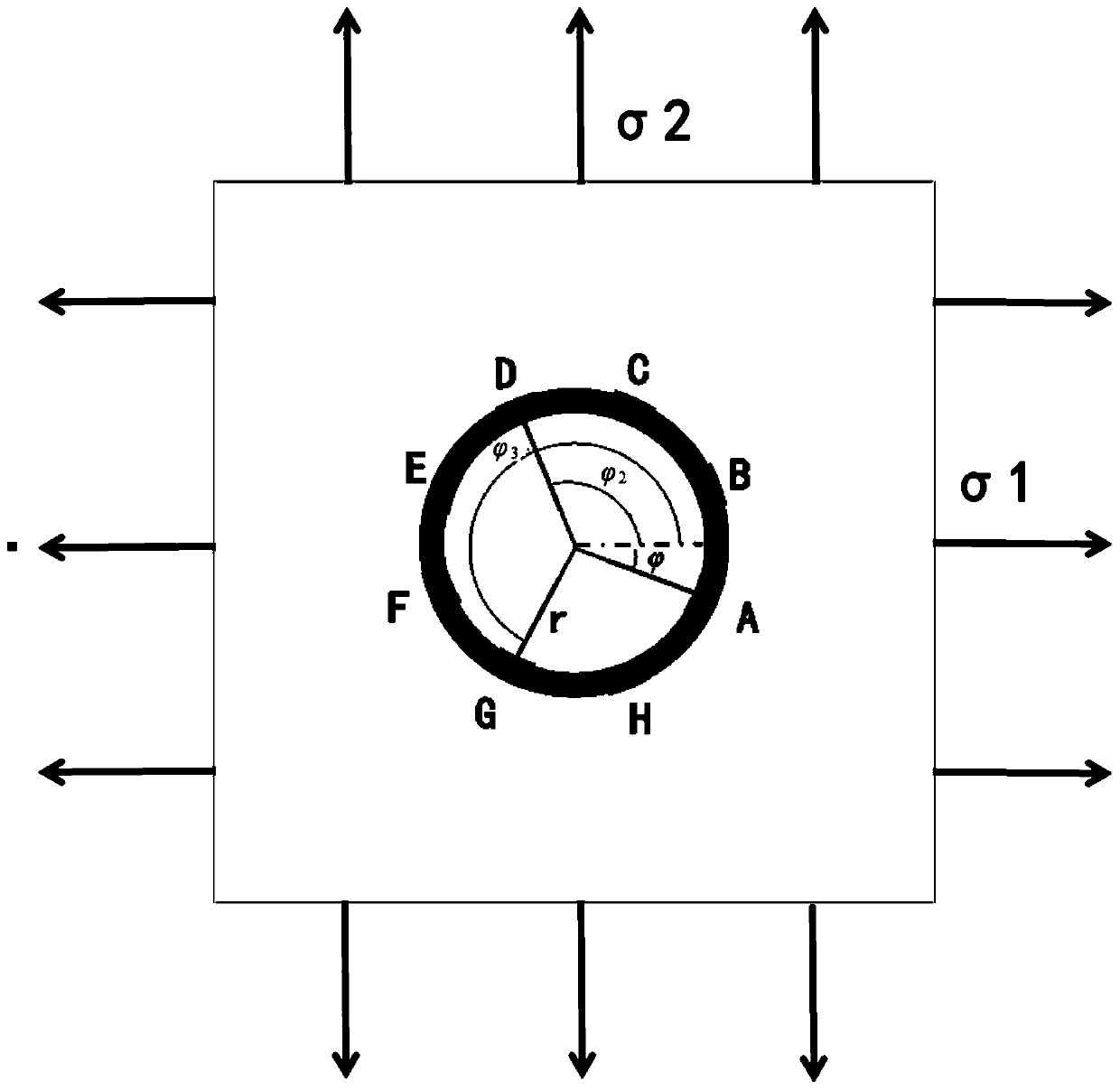

[0068] Step 2. Put 8 fiber optic sensors (such as image 3 The optical fiber sensors A, B, C, D, E, F, G, H) are connected in series through the transmission optical fiber 2 and wound into a circle to form an optical fiber sensor ring 1; location;

[0069] Step 3. Complete the connection between the optical fiber sensor ring 1 and the demodulation device 3, and the connection between the demodulation device 3 and the data processing device 4;

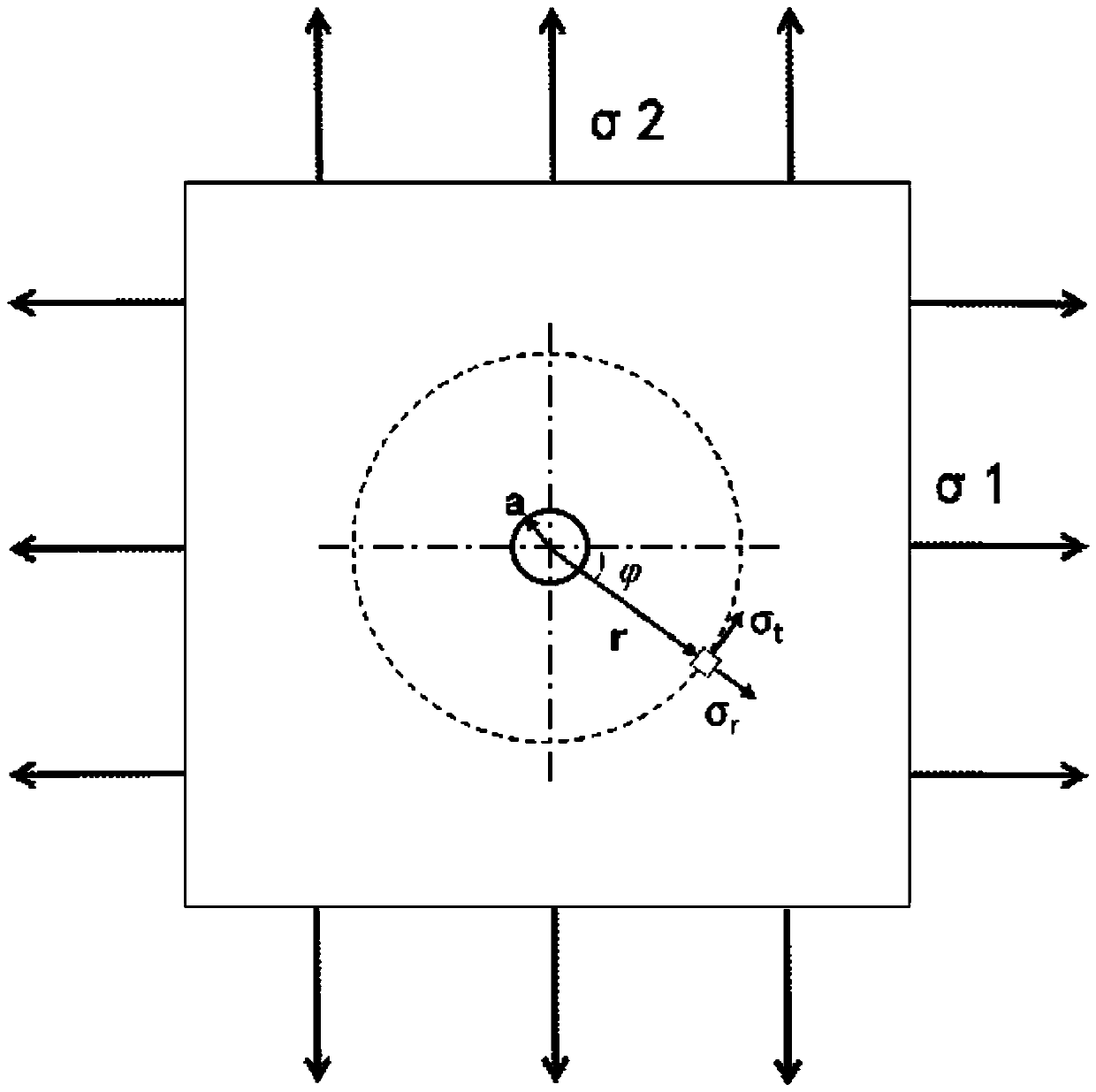

[0070] Step 4. Before drilling, the optical fiber sensor ring 1 tests the wavelength signals of each m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com