Multifunctional inorganic composite foam concrete modifier and preparation method thereof

A foamed concrete and inorganic composite technology, applied in the field of building material additives and building materials, can solve the problems of high thermal conductivity, poor waterproofness, low strength, etc., achieve uniform and dense cells, increase compressive strength, and improve cell structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

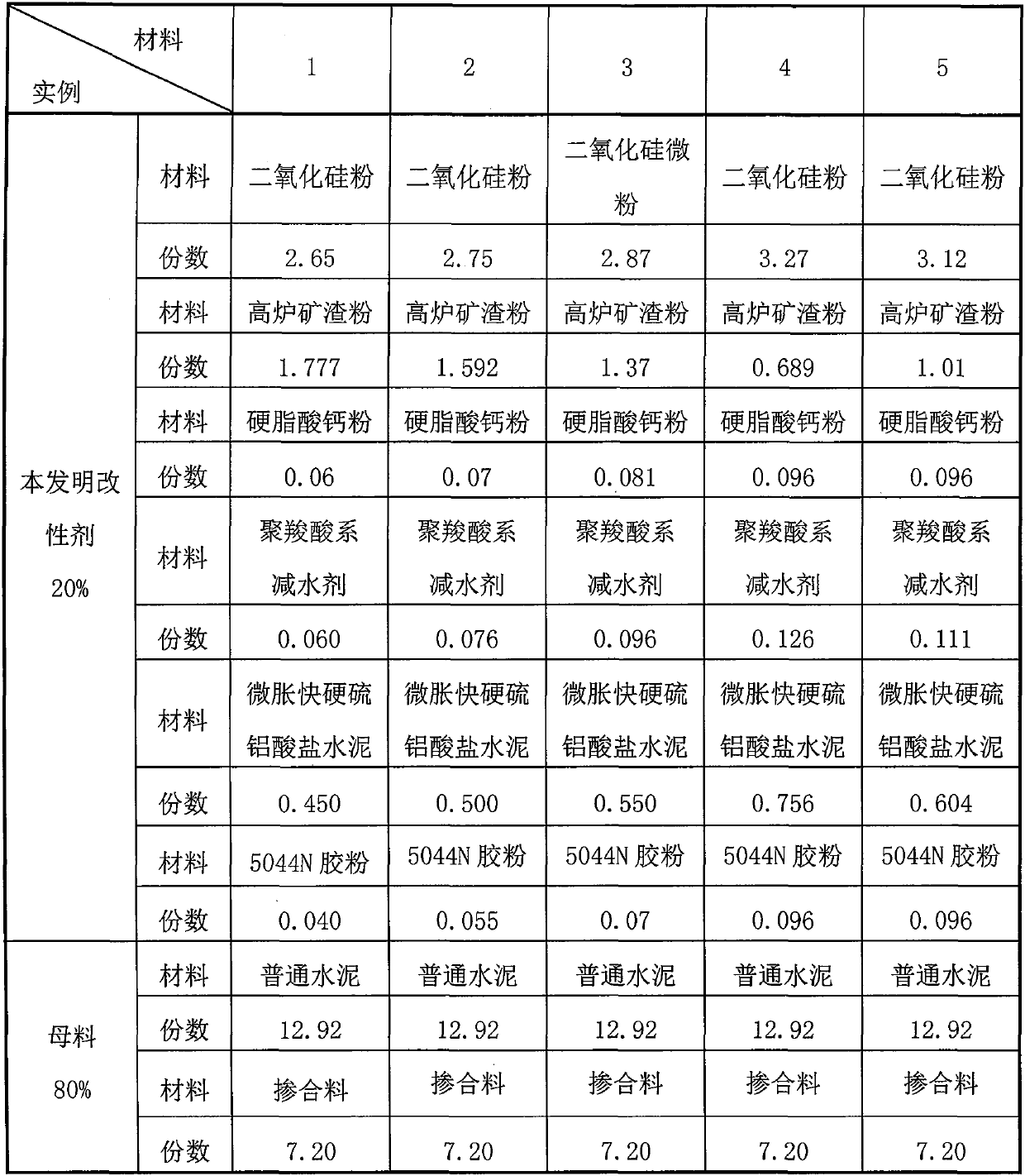

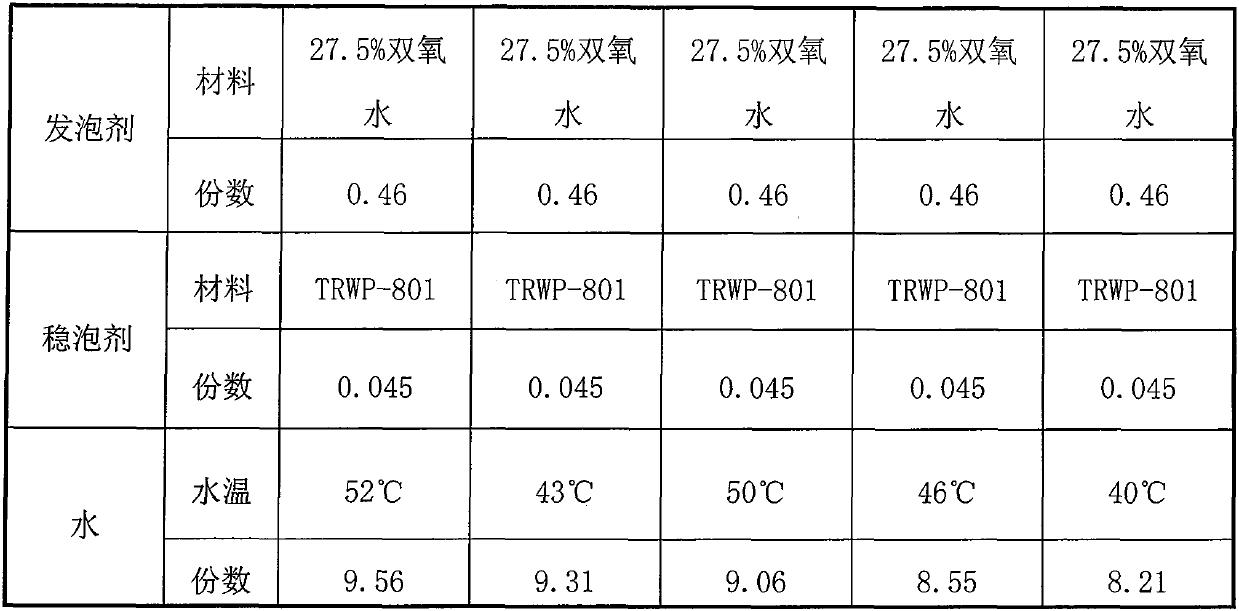

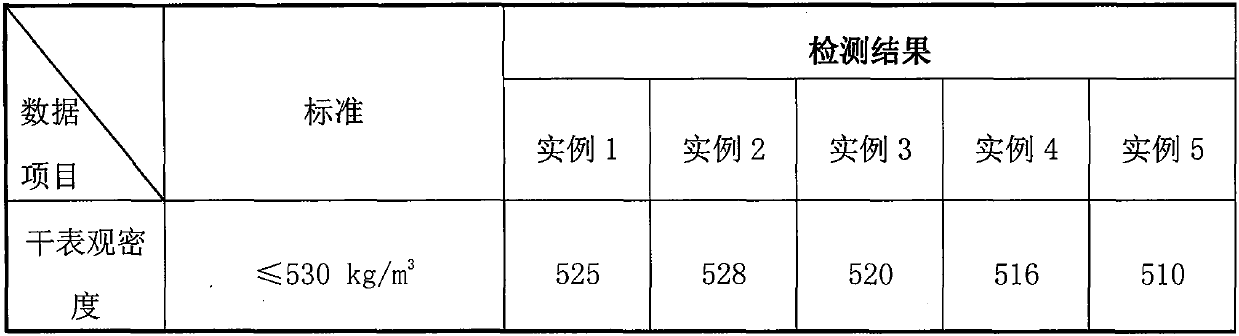

[0041] The technical solutions of the present invention are described below with specific examples, but the scope of protection of the present invention is not limited thereto: See Table 1 below for the proportions by weight of the masterbatches and auxiliary materials in Examples 1-5.

[0042] Table 1 specific implementation table

[0043]

[0044]

[0045] The raw materials used in the examples are all commercially available products.

[0046] The preparation method of modifier modified foam concrete of the present invention described in embodiment comprises the following steps:

[0047] (1) water is joined in the agitator by parts by weight;

[0048] (2) Add modifier of the present invention, foam stabilizer etc. to step (1) by weight parts and stir for 0.5min to obtain uniform slurry;

[0049] (3) Add the master batch into the homogeneously mixed slurry in step (2) by parts by weight and stir for 2.5min to obtain a uniform slurry;

[0050] (4) Add foaming agent to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com