Thermal insulation mortar for thermal insulation prefabricated part of building wall, and preparation method and equipment

A technology for building walls, heat preservation and heat insulation, applied to building components, heat preservation, clay preparation equipment, etc., can solve the problems of poor encapsulation of polyphenylene particles, unclosed feeding ports, and high preparation costs, and improve the quality of laying and plastering. Efficiency, reduced preparation cost, and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

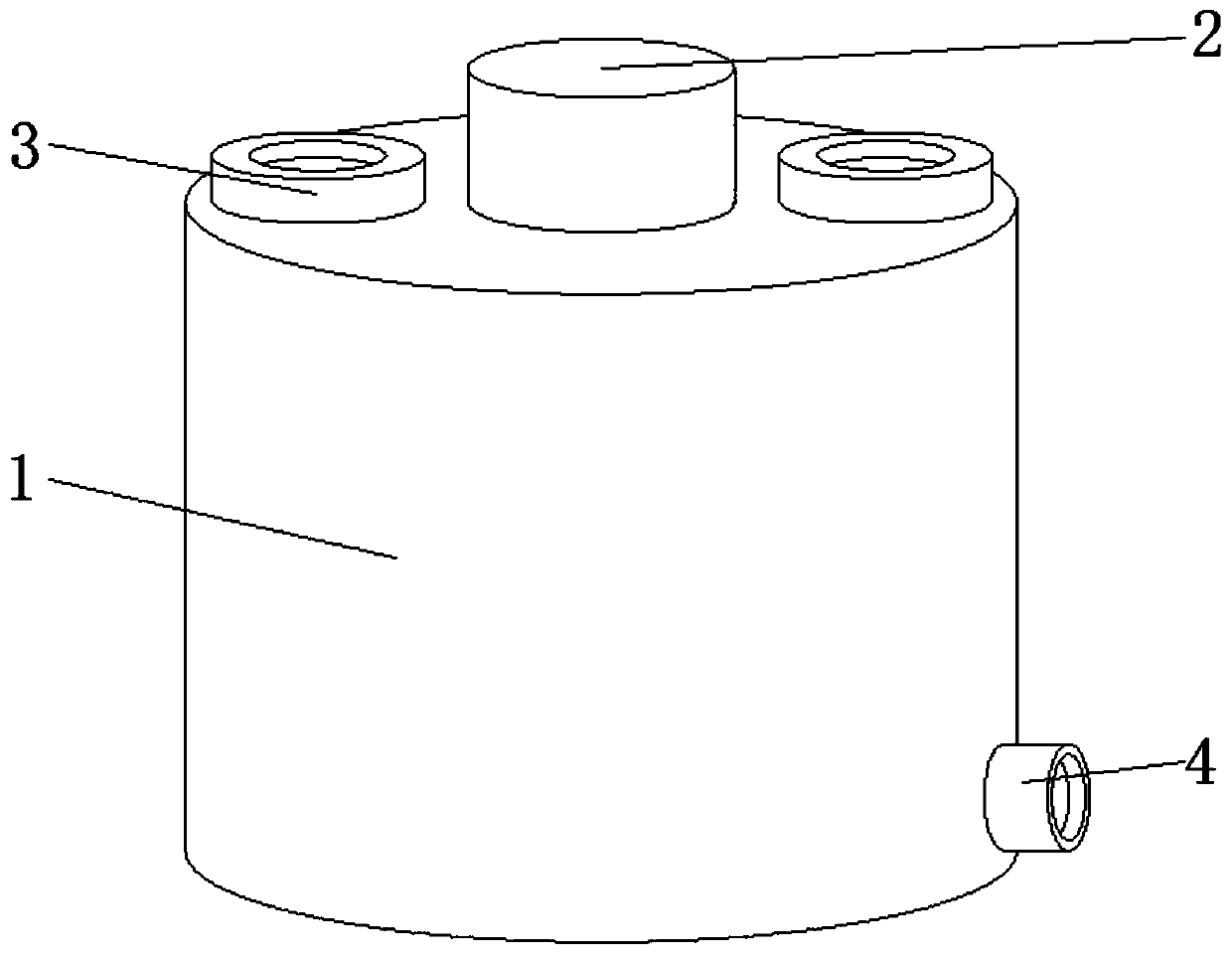

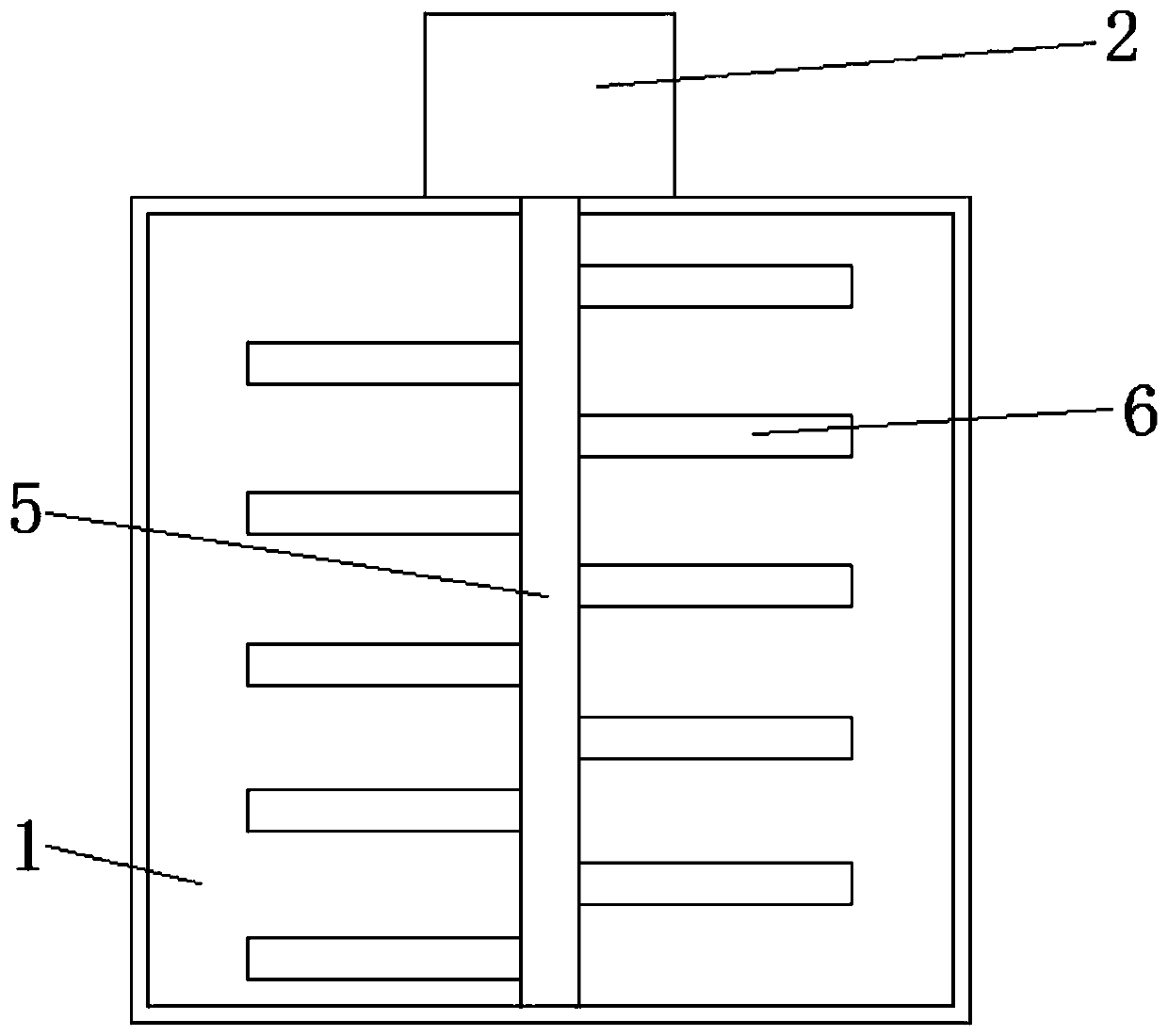

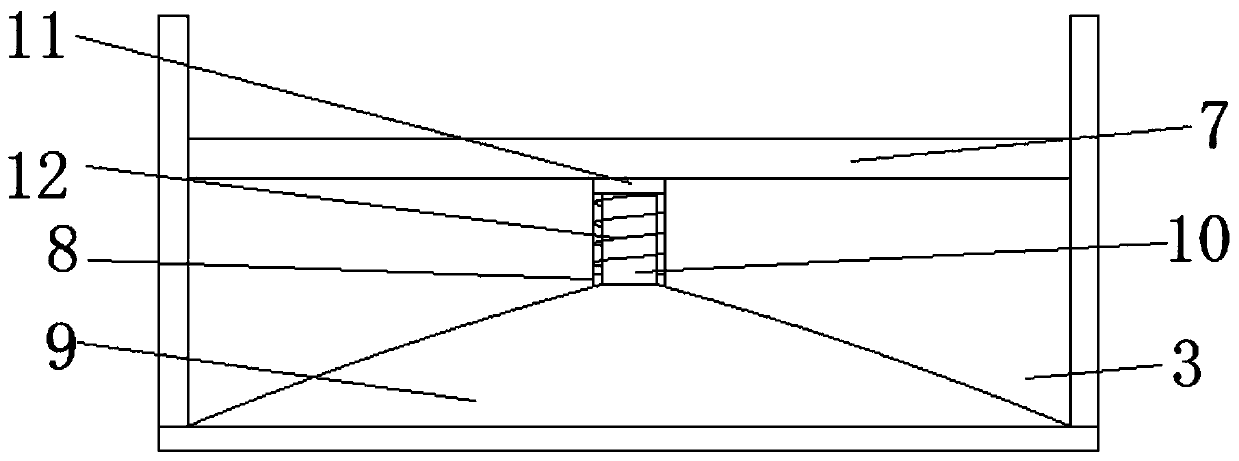

[0030] see Figure 1 to Figure 3 , the thermal insulation mortar for building wall thermal insulation prefabricated parts provided by the present embodiment is made of the following components in parts by weight: 350 parts of Portland cement, 7 parts of polyphenylene particles, 100 parts of lime calcium powder, quartz sand 520 parts, 20 parts of silica fume, 15 parts of modified seaweed, 15 parts of concrete admixture, and the balance of water.

[0031] A preparation method for thermal insulation mortar for building wall thermal insulation prefabricated parts, which comprises the following steps:

[0032] S1: First filter the quartz sand through a 60-mesh screen, then add Portland cement, lime calcium powder, quartz sand, and silica fume into the mixing tank and mix with water until it becomes a viscous gel;

[0033] S2: Add polyphenylene particles into the mixture of S1 and stir evenly;

[0034] S3: Add the modified seaweed and concrete admixture to the mixture of S2 and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com