Self-vulcanized chloroprene rubber/natural rubber lining composition and application method thereof

A technology of rubber lining and neoprene, applied in the fields of rubber polymer materials and new materials, can solve the problems of difficult rubber lining and unsuitability to move, improve the service life, improve the softness, and solve the problems of bubbling and warping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

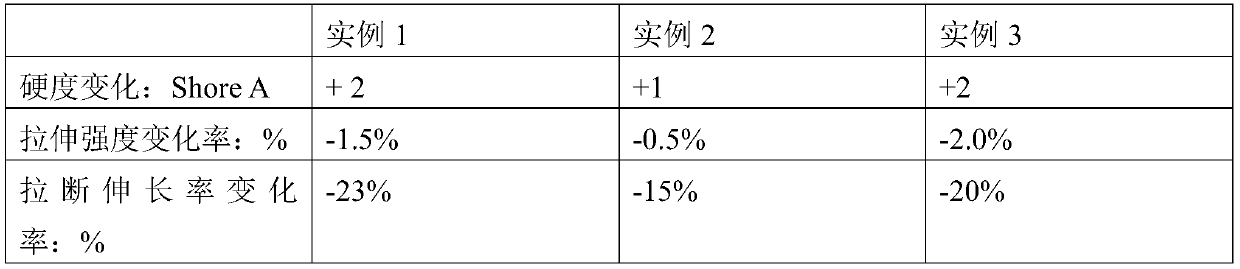

Examples

Embodiment 1

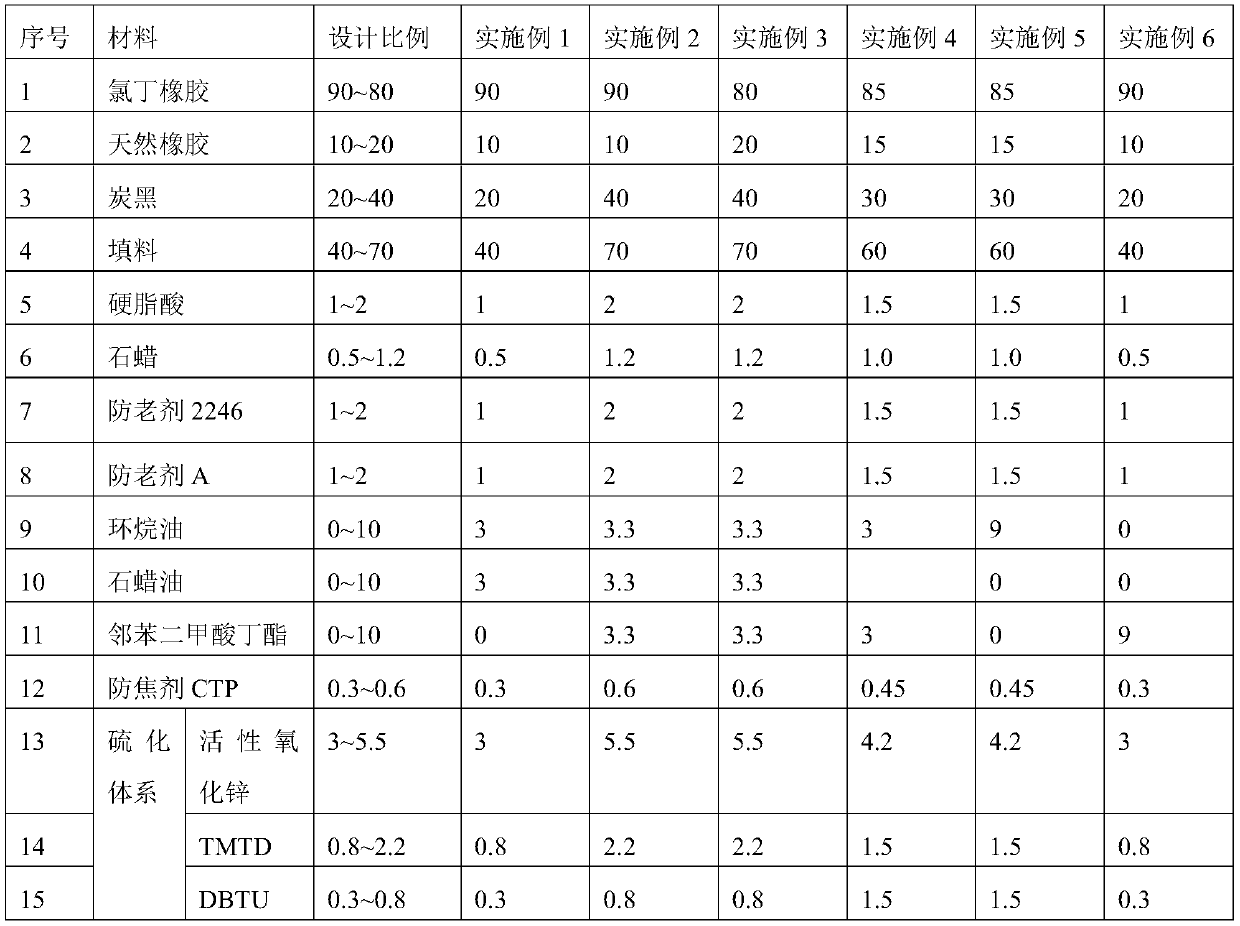

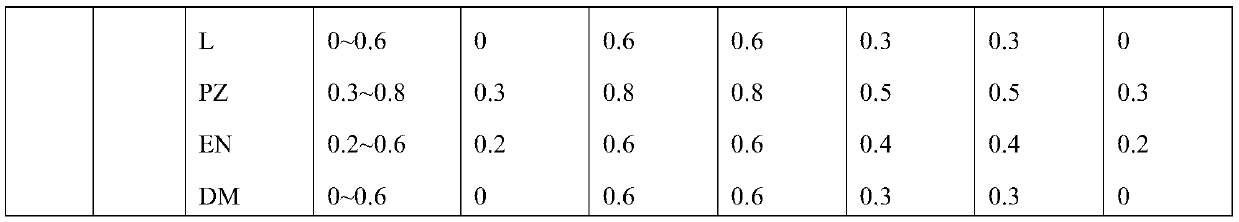

[0032] Neoprene / natural rubber is 90 / 10, and the remaining materials are about the lower limit of the design formula ratio, and then implement according to the following steps.

[0033] (1) According to the volume of the internal mixer, weigh each material according to the ratio of scheme 1 in Table 1

[0034]

[0035]

[0036] (2) After the natural rubber is masticated in the internal mixer for 1 min, 0.5% peptizer is added, and the mastication is continued until the rubber is discharged into the hopper at 85°C, then transferred to the open mixer, and pressed into slices, cut into small rolls, and the weight of each roll is according to the weight specified in Scheme 1, and it is used for mixing after parking for 8 hours;

[0037] (3) Add the parked natural rubber plastic compound to the internal mixer, and then add the neoprene rubber to the internal mixer after banburying for 0.5-1min, and banbury for 1-3min. Add the materials in item 11 to the banburying, and discha...

Embodiment 2

[0045] Compared with Example 1, the ratio of chloroprene rubber and natural rubber is kept constant, and the amount of materials used in Items 3 to 15 is about the upper limit of the design ratio.

Embodiment 3

[0047] Compared with Example 2, the ratio of neoprene / natural rubber is changed to: 80 / 20, and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com