Application of Peptostreptococcus asaccharoly glutamate dehydrogenase (GdhA) in increasing yield of Bacillus licheniformis poly-gamma-glutamic acid

A technology of Bacillus licheniformis and glutamate dehydrogenase, which is applied in the fields of enzyme engineering and genetic engineering, can solve problems such as the comparison and unanalyzed research of glutamate dehydrogenase without research on Bacillus glutamate dehydrogenase , to achieve the effect of increasing the synthesis level of poly-γ-glutamic acid and improving the effect of poly-γ-glutamic acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Construction of Peptostreptococcus glutamate dehydrogenase replacement strain Bacillus licheniformis WX-gdhA:

[0025] 1. According to the genome DNA sequence of Peptostreptococcus asaccharolyticus DSM 20463, the gdhA gene (gene amplification primers are T2-F2 and T2-R2) (shown in SEQ ID NO.2) is synthesized by gene; WX-02 genomic DNA was used as a template, and the upstream homology arm of the glutamate dehydrogenase gene rocG of Bacillus licheniformis itself (primers T2-F1 and T2-R1) and the downstream homology arm of the gene rocG (primers T2-R1) were amplified by PCR. for T2-F3 and T2-R3);

[0026] T2-F1:GCTCTAAGAGCGGCTGATGAAGGT

[0027] T2-R1:ACGGATTAAGTGTATCTGTCATTAACAGGCACGCCAAAAG

[0028] T2-F2: CTTTTGGCGTGCCTGTTAATGACAGATACACTTAATCCGT

[0029] T2-R2: CGCTAAGACTTCCAGGTGATTAATACCATCCTCTAATTTC

[0030] T2-F3:GAAATTAAGAGGATGGTATTAATCACCTGGAAGTCTTAGCG

[0031] T2-R3: CGAGCT ATCAAAAACAGAAGGGGGAGGA

[0032] 2. Connect the upstream homology arm of the gene rocG, ...

Embodiment 2

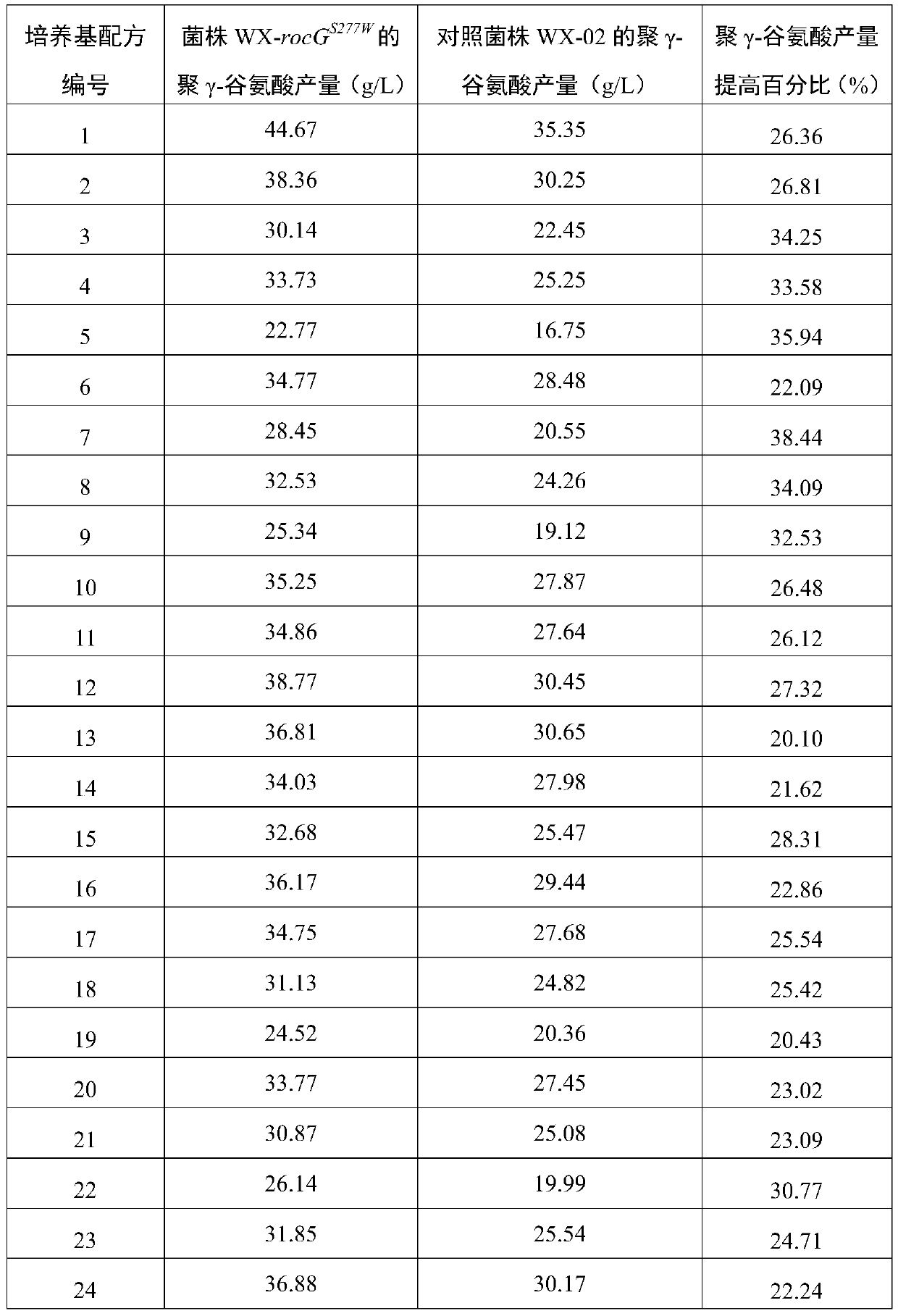

[0043] Application of Bacillus licheniformis WX-gdhA in improving the fermentation yield of poly-γ-glutamic acid:

[0044] Fermentation Product Yield Analysis

[0045] The recombinant bacterial strain obtained in Example 1 was inoculated into LB medium, cultivated at 37°C for 14 hours; 50 mL of poly-γ-glutamic acid fermentation medium (Table 1) was loaded into a 500 mL Erlenmeyer flask, and then the seed-cultured bacteria The solution was inoculated into the fermentation medium with an inoculum amount of 3% (volume percentage). The culture conditions are 230 r / min, 37° C., and 36 hours of fermentation period.

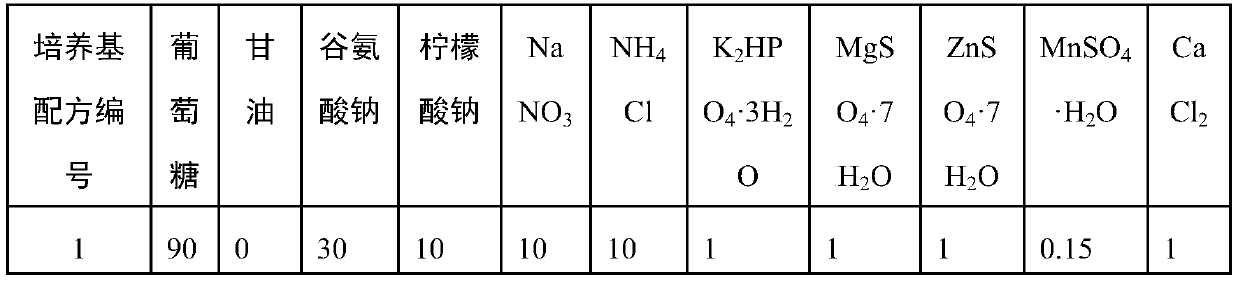

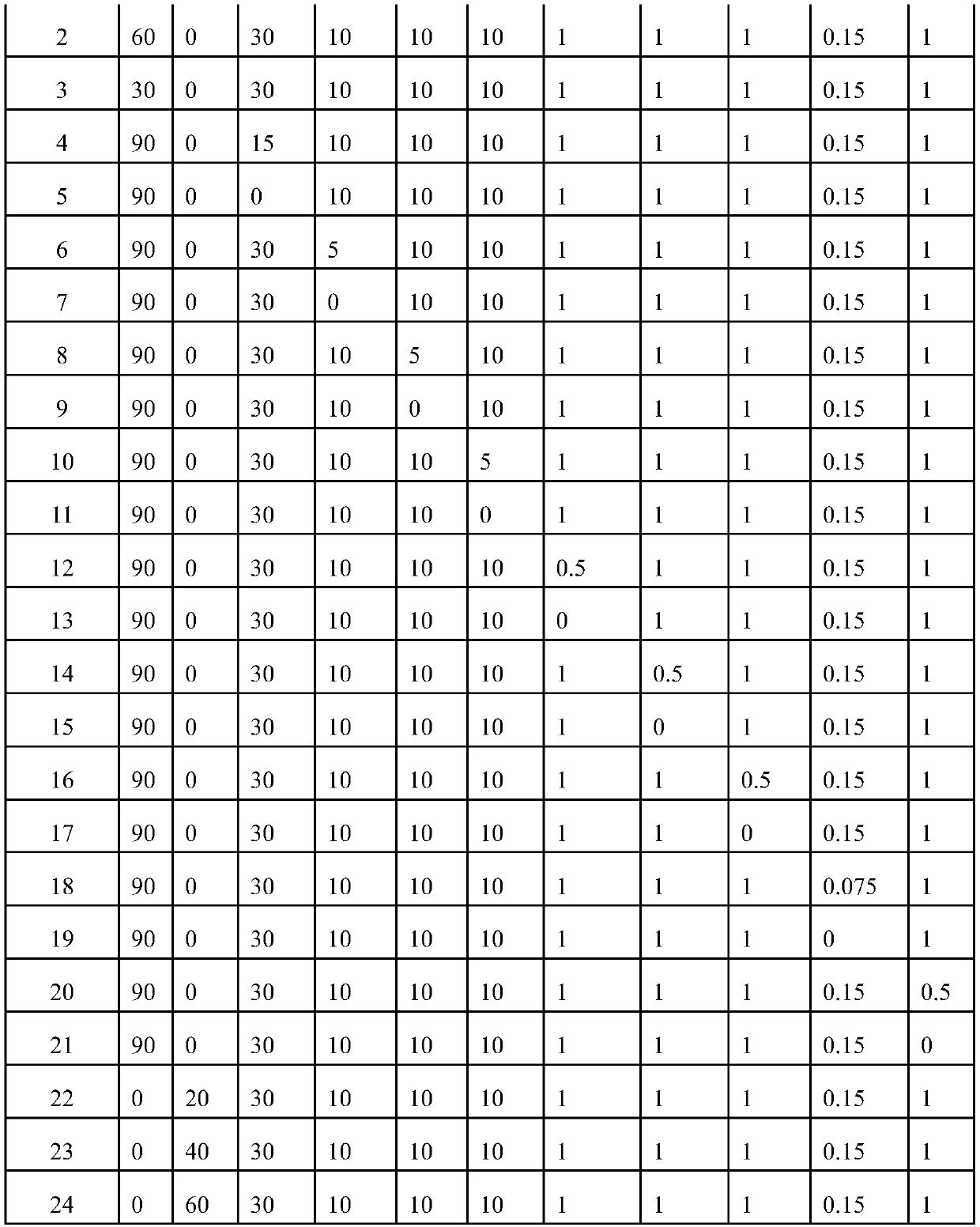

[0046] In this example, for different fermentation medium formulations, the influence of Bacillus licheniformis WX-gdhA on the synthesis level of poly-γ-glutamic acid was investigated (while also inoculating Bacillus licheniformis WX with the same inoculum amount in these 24 kinds of media) -02 as a contrast), 24 groups of culture medium formulations are specifically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com