Recombinant corynebacterium glutamicum for efficiently synthesizing high-purity hyaluronic acid and oligosaccharides thereof

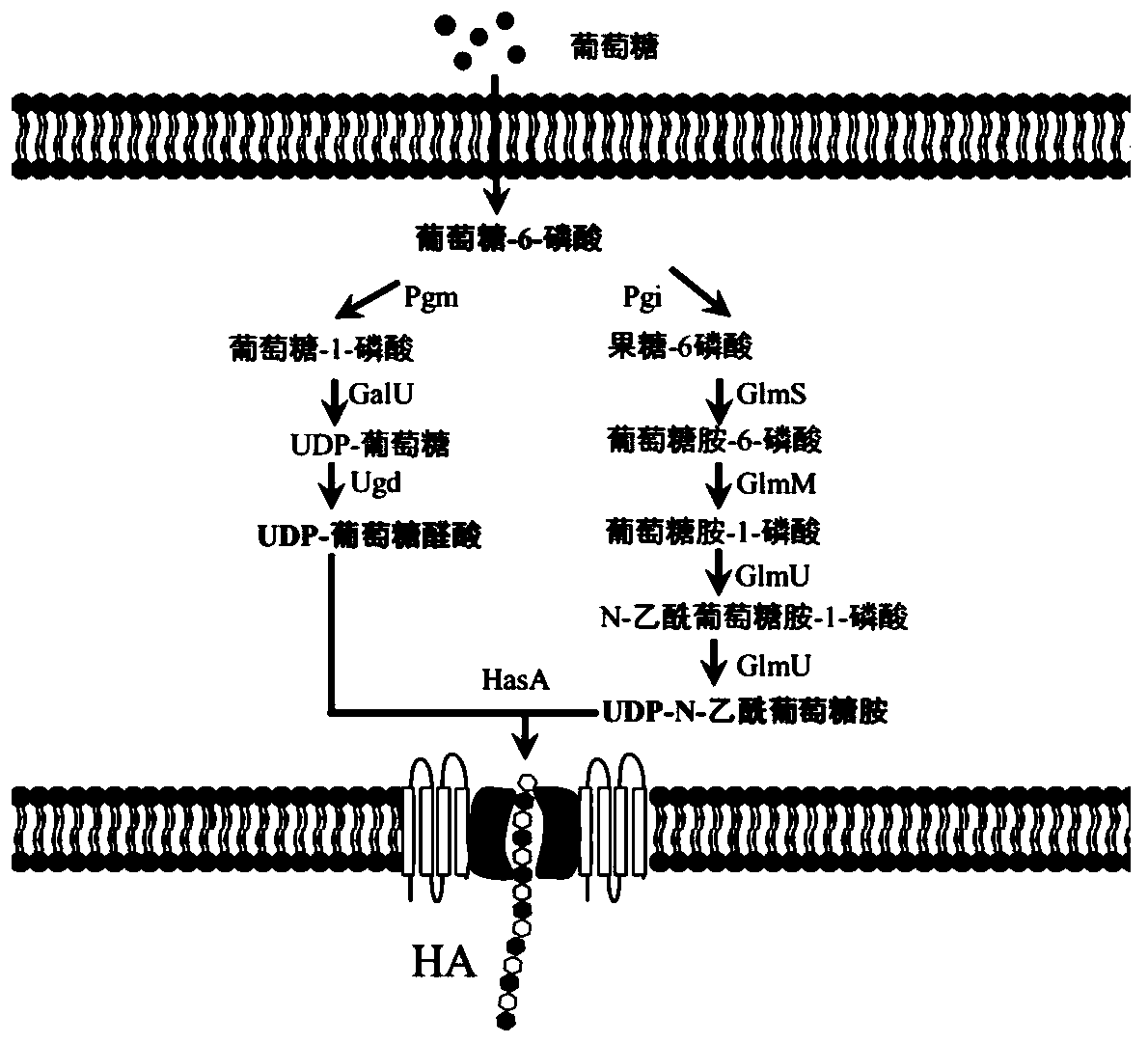

A technology of Corynebacterium glutamicum and hyaluronic acid, which is applied in the field of bioengineering, can solve the problems of reducing the quality of hyaluronic acid products and increasing the difficulty of downstream hyaluronic acid purification, so as to achieve the goal of increasing yield and purity and improving synthesis capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the construction of recombinant Corynebacterium glutamicum

[0039] (1) Knockout of genes cg0420 and cg0424

[0040] Using the genomic DNA of Corynebacterium glutamicum ATCC13032 as a template and using 0420-up-F and 0420-up-R as primers to perform PCR, obtain a fragment 0420-up about 500 bp upstream of cg0420 and perform PCR product purification;

[0041] Using the genomic DNA of Corynebacterium glutamicum ATCC13032 as a template, and using 0420-down-F and 0420-down-R as primers, PCR was carried out to obtain a fragment 0420-down about 500 bp downstream of cg0420 and purify the PCR product;

[0042] The Corynebacterium glutamicum suicide plasmid pK18mobsacB was double-digested with EcoRI / BamhI, and the 0420-up and 0420-down fragments were ligated to the pK18mobsacB after digestion with the GibsonAssembly kit in one step, and the recombinant plasmid obtained was named pK18- 0420;

[0043] The plasmid pK18-0420 was transformed into Corynebacterium glutami...

Embodiment 2

[0067] Embodiment 2: recombinant Corynebacterium glutamicum produces hyaluronic acid

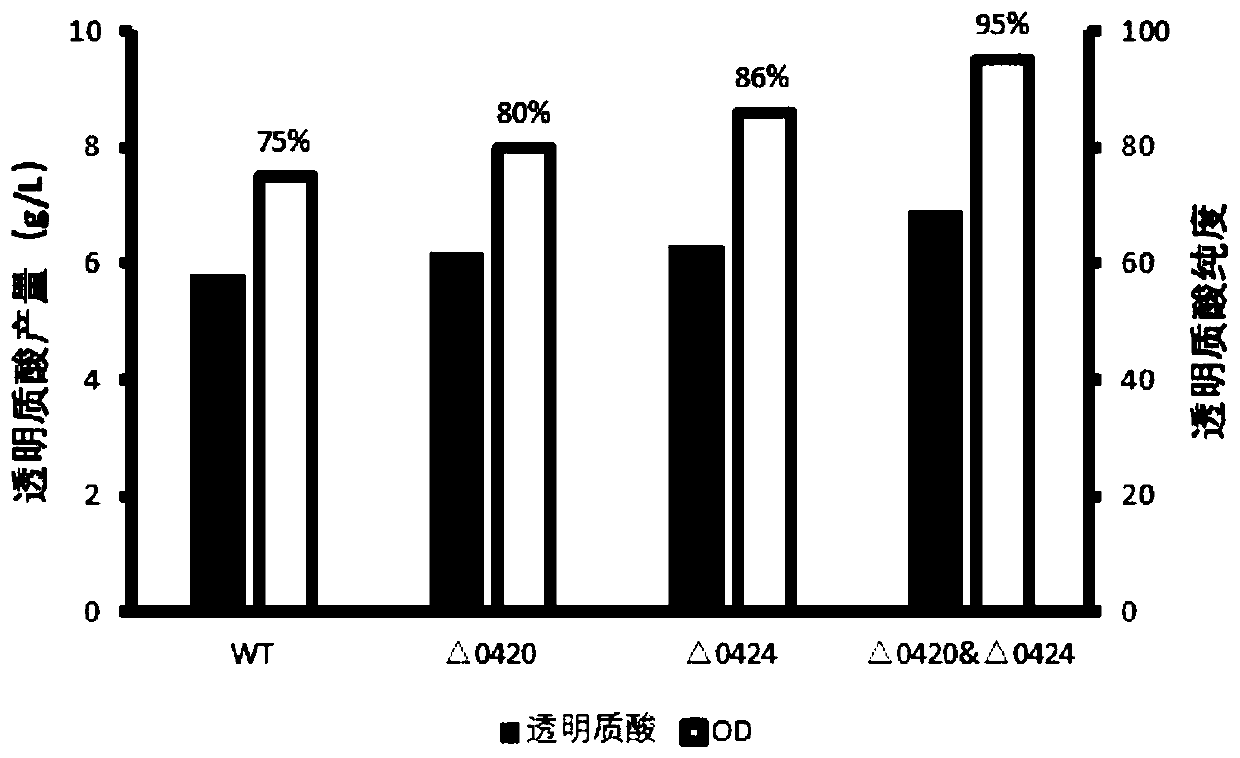

[0068] The constructed recombinant Corynebacterium glutamicum strains: WT, △0420, △0424 and △0420&△0424 were single-cloned in 5ml BHI medium, 200rpm, 30°C overnight culture. After 10 hours, transfer to 250ml Erlenmeyer shake flask (filling liquid volume is 25ml fermentation medium) according to 1% inoculum amount. Placed at 200rpm, cultivated at 28°C, cultivated for three hours, and added IPTG with a final concentration of 0.25Mm to induce gene expression. The fermentation period was 48 hours. After the fermentation, take the supernatant and add four times the volume of ethanol for alcohol precipitation to remove some Impurities, after repeated alcohol precipitation twice, the content of hyaluronic acid was determined by the sulfuric acid carbazole method, from figure 2 It can be seen that by knocking out cg0420, the yield and purity of hyaluronic acid in cg0424 have been improved to a cer...

Embodiment 3

[0069] Embodiment 3: the 5L fermenter fermentation culture of recombinant Corynebacterium glutamicum

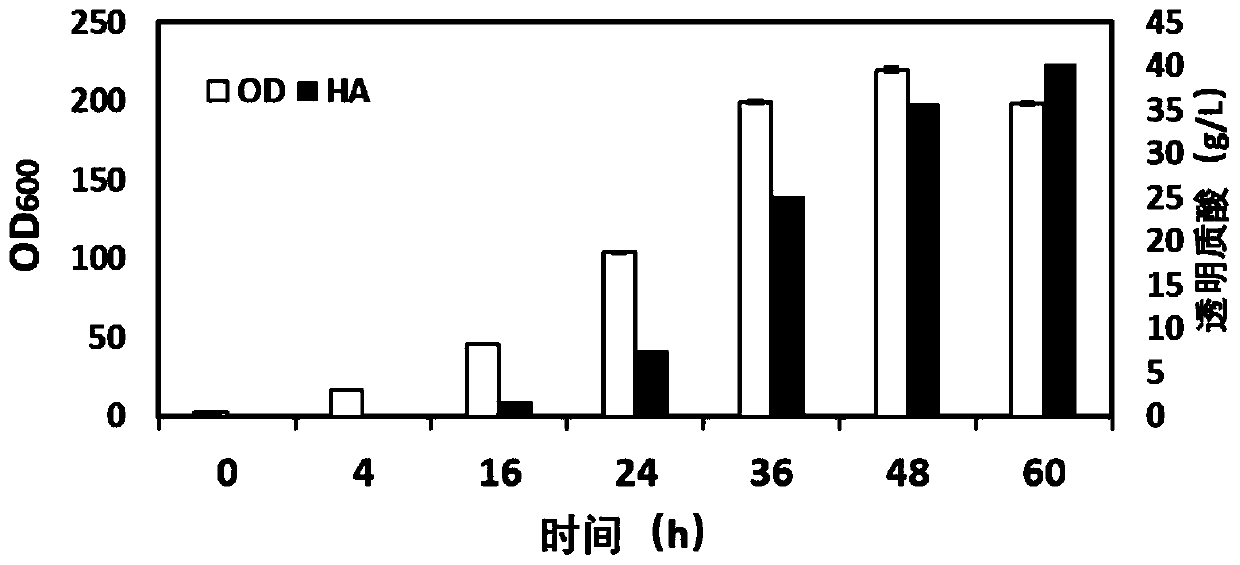

[0070] The recombinant Corynebacterium glutamicum bacterial strain that will construct: Corynebacterium glutamicum HasA-VGB / pXMJ19-pgm-ugd-galU, pECX99E-glmU-glmM-glmS (knockout cg0420, cg0424) receive single clone in 5mlBHI medium, 200rpm, Incubate overnight at 30°C. After 10 hours, the inoculum was transferred to a 250 ml Erlenmeyer shaker flask (filling liquid volume is 25 ml fermentation medium) according to the inoculum amount of 1%. Placed at 200rpm, cultured at 28°C for 10h, inoculated in the fermenter with 10% inoculation amount, maintained the glucose content in the fermenter at about 10g / L by feeding glucose during the fermentation process, and controlled the pH to be neutral by feeding NaOH properties, and exogenously added hyaluronan hydrolase with a final concentration of 6000U / mL at 20h of fermentation, the fermentation period was 72h, from image 3 It can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com