Preparation method of baked pine nuts

A technology of baking pine nuts with variable temperature, which is applied in food science and other fields, and can solve the problems of short shelf life, low opening rate, and easy drop, and achieve the effects of less nutritional loss, good nutritional value, and fragrance retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

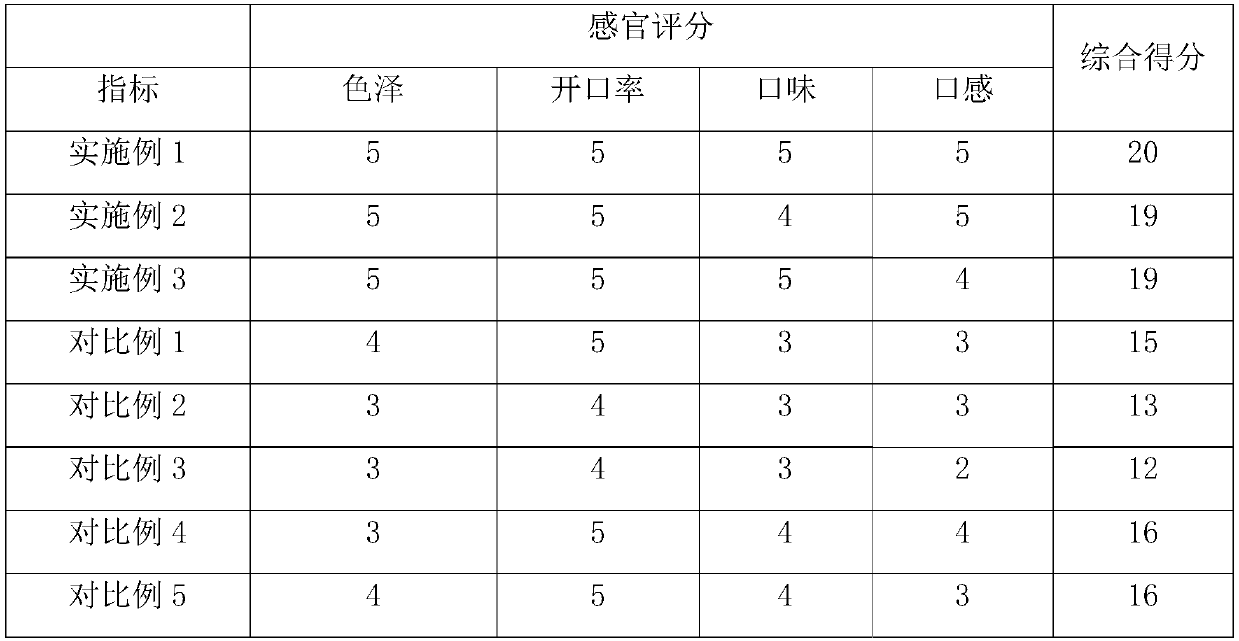

Embodiment 1

[0023] The present embodiment provides a method for processing roasted pine nuts, comprising the steps of:

[0024] Step S1, after the pine nut raw materials are manually selected to remove impurities, bad seeds and other unqualified raw materials, soak in cold water for 5 hours, drain and set aside;

[0025] Step S2, pour the above-mentioned soaked pine nut raw material into a grinder, and add 30 mesh river sand in a weight ratio of 20% (the mass ratio of pine nuts to river sand is 50:1);

[0026] Step S3, adjust the grinding machine to a speed of 20r / min, process for 30min, then export the material and filter out the river sand, manually open the pine nuts, and then set aside;

[0027] Step S4, pour the raw material of pine nuts processed in the above step S3 into an oven, and bake at 90±5°C for 120 minutes, then at 115±5°C for 50 minutes;

[0028] In step S5, pour out the above-mentioned roasted pine nut raw material, let it cool down naturally, and select to obtain the ro...

Embodiment 2

[0030] The present embodiment provides a method for processing roasted pine nuts, comprising the steps of:

[0031] Step S1, after the pine nut raw materials are manually selected to remove impurities, bad seeds and other unqualified raw materials, soak in cold water for 4 hours, drain and set aside;

[0032] Step S2, pour the above-mentioned soaked pine nut raw material into a grinder, and add 20 mesh river sand in a weight ratio of 2% (the mass ratio of pine nuts to river sand is 50:1);

[0033] Step S3, adjust the grinding machine to a speed of 15r / min, process for 60 minutes, then export the material and filter out the river sand, manually open the pine nuts, and then set aside;

[0034] Step S4, pour the raw material of pine nuts processed in the above step S3 into an oven, and bake at 90±5°C for 60 minutes, and then bake at 115±5°C for 120 minutes;

[0035] In step S5, pour out the above-mentioned roasted pine nut raw material, let it cool down naturally, and select to ...

Embodiment 3

[0037] The present embodiment provides a method for processing roasted pine nuts, comprising the steps of:

[0038] Step S1, after the pine nut raw materials are manually selected to remove impurities, bad seeds and other unqualified raw materials, soak in cold water for 7 hours, drain and set aside;

[0039] Step S2, pour the above-mentioned soaked pine nut raw materials into a grinder, and add 40 mesh river sand in a weight ratio of 10% (the mass ratio of pine nuts to river sand is 10:1);

[0040] Step S3, adjust the grinding machine to a speed of 50r / min, process for 20 minutes, then export the material and filter out the river sand, manually open the pine nuts, and then set aside;

[0041] Step S4, pouring the raw material of pine nuts processed in the above step S3 into an oven, first baking at 90±5°C for 180 minutes, and then baking at 115±5°C for 30 minutes;

[0042] In step S5, pour out the above-mentioned roasted pine nut raw material, let it cool down naturally, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com