A kind of polysaccharide-modified acellular matrix composite material, preparation and application

A composite material, cell-free technology, applied in the direction of prosthesis, tissue regeneration, medical science, etc., can solve the problems of easy degradation, urine leakage, low mechanical strength, etc., achieve good biocompatibility, low immunogenicity, compactness good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

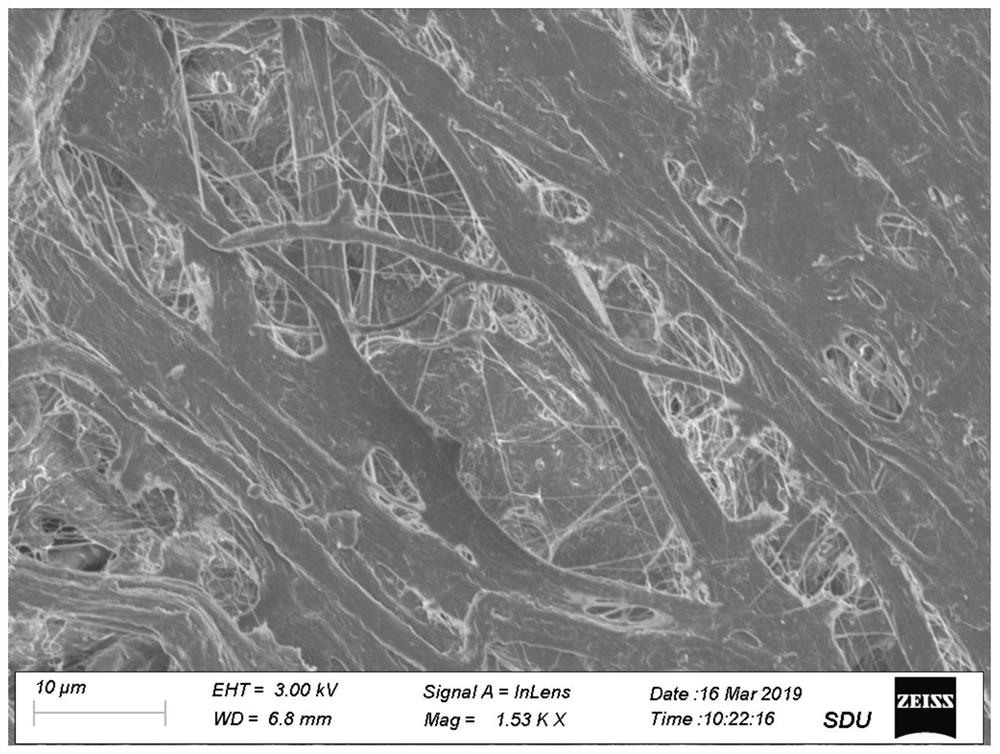

[0041] This implementation provides a polysaccharide-containing modified acellular bladder matrix composite material, which is prepared by the following steps:

[0042] (1) Cut off large pieces of fat, fascia and other tissues from the bladder purchased in the market, wash it repeatedly with PBS buffer and weigh it as the basis for the calculation of the following procedures;

[0043](2) Alkali treatment: at a temperature of 28°C, at a ratio of 3:1 to pig bladder, add NaOH and Triton X-100 solutions with a mass concentration of 0.4% (the mass concentrations of NaOH and Triton X-100 in this solution are both 0.4% ), act for 16 hours to fully remove the fibrous interstitium and remove cells; after completion, add distilled water and wash three times with a material-to-liquid ratio of 1:4, each time for 15 minutes.

[0044] (3) Eliminate lye: According to the ratio of solid to liquid to pig bladder mass 3.0, temperature 30°C, add NH with a concentration of 2% 4 CL solution. The...

Embodiment 2

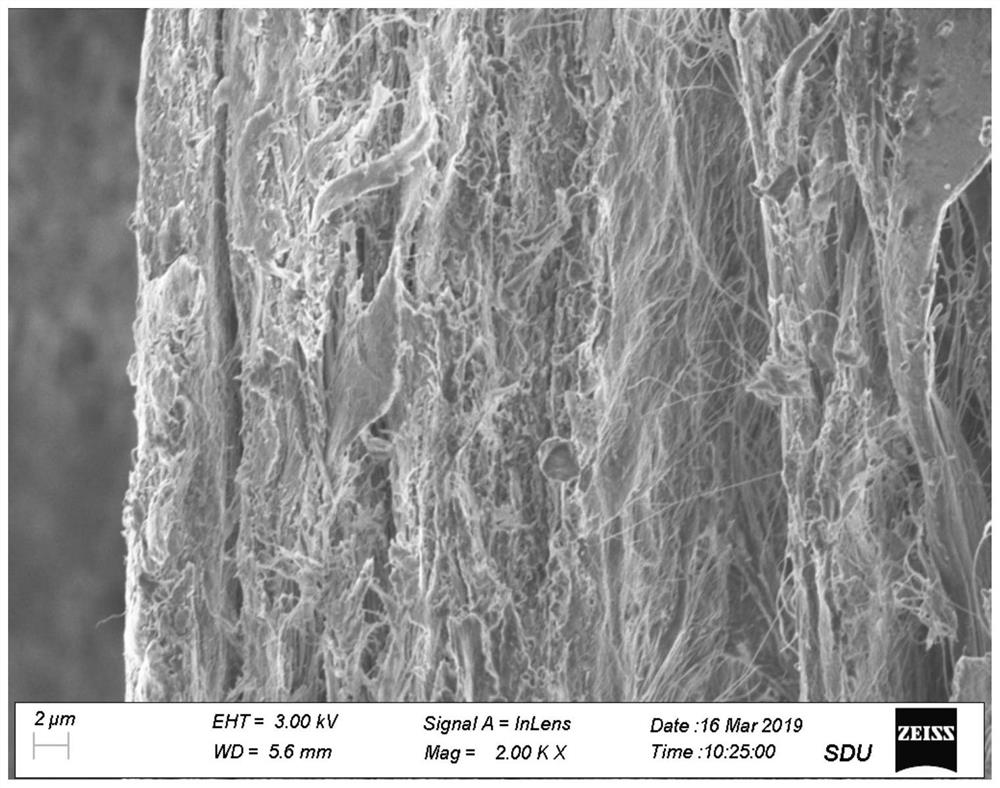

[0055] This implementation provides a polysaccharide-containing modified acellular bladder matrix composite material, which is prepared by the following steps:

[0056] (1) Cut off large pieces of fat, fascia and other tissues from the bladder purchased in the market, wash it repeatedly with PBS buffer and weigh it as the basis for the calculation of the following procedures;

[0057] (2) Alkali treatment: at a temperature of 28°C, at a ratio of 5:1 to pig bladder, add NaOH and Triton X-100 solutions with a mass concentration of 0.3% (the mass concentrations of NaOH and Triton X-100 in this solution are both 0.3% ), act for 13 hours, fully remove the fibrous interstitium and remove the cells; after completion, add distilled water and wash three times according to the ratio of material to liquid 4:1, each time for 15 minutes.

[0058] (3) Eliminate lye: According to the ratio of solid to liquid of pig bladder mass 5:1, temperature 30°C, add NH with a concentration of 1.8% 4 Cl...

Embodiment 3

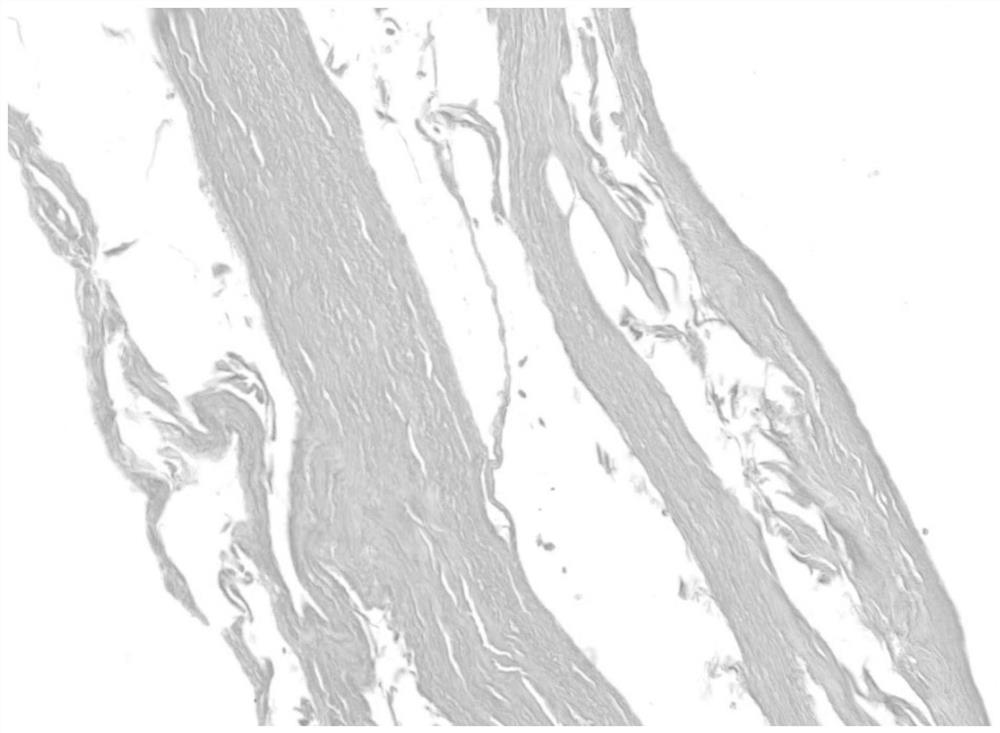

[0069] This implementation provides a polysaccharide-containing modified acellular bladder matrix composite material, which is prepared by the following steps:

[0070] (1) Cut off large pieces of fat, fascia and other tissues from the bladder purchased in the market, wash it repeatedly with PBS buffer and weigh it as the basis for the calculation of the following procedures;

[0071] (2) Alkali treatment: at a temperature of 28°C, according to the ratio of solid to pig bladder to liquid of 3:1, add NaOH and TritonX-100 solutions with a mass concentration of 0.38% (the mass concentrations of NaOH and Triton X-100 in this solution are both 0.38% ), act for 18 hours, fully remove the fibrous interstitium and remove the cells; after completion, add distilled water and wash three times according to the ratio of material to liquid 1:4, each time for 15 minutes.

[0072] (3) Eliminate lye: according to the ratio of solid to liquid of pig bladder mass 3:1, temperature 30°C, add NH wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com