A preparation process of cold heat-clearing granules with effects of clearing heat and relieving exterior syndromes

A preparation process, a technology for clearing heat from a cold, is applied in the field of preparation of granules for clearing heat and can solve the problems of reduced processing efficiency, inconvenient material addition and the like, and achieves the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation process of Ganmao Qingre Granules capable of clearing away heat and detoxifying the exterior, the specific preparation process is as follows:

[0034] In the first step, extract volatile oil from 200g nepeta panicles, 60g peppermint, and 60g perilla leaves, and collect the distilled aqueous solution in another device;

[0035] In the second step, decoct the medicinal dregs extracted in the first step with 100g Fangfeng, 100g Bupleurum, 100g Pueraria, 60g Campanulaceae, 80g Bitter almond, 60g Angelica dahurica, 200g Kudiding, 160g Reed Rhizome twice, and then Filtrate, and combine the filtrate with the aqueous solution in the first step, and concentrate the combined product into a clear paste with a relative density of 1.32-1.35 (50° C.);

[0036] In the third step, add an appropriate amount of sucrose, dextrin and ethanol to the clear paste prepared in the second step to make granules, then dry them and use the lifting and feeding mechanism in the bagging ...

Embodiment 2

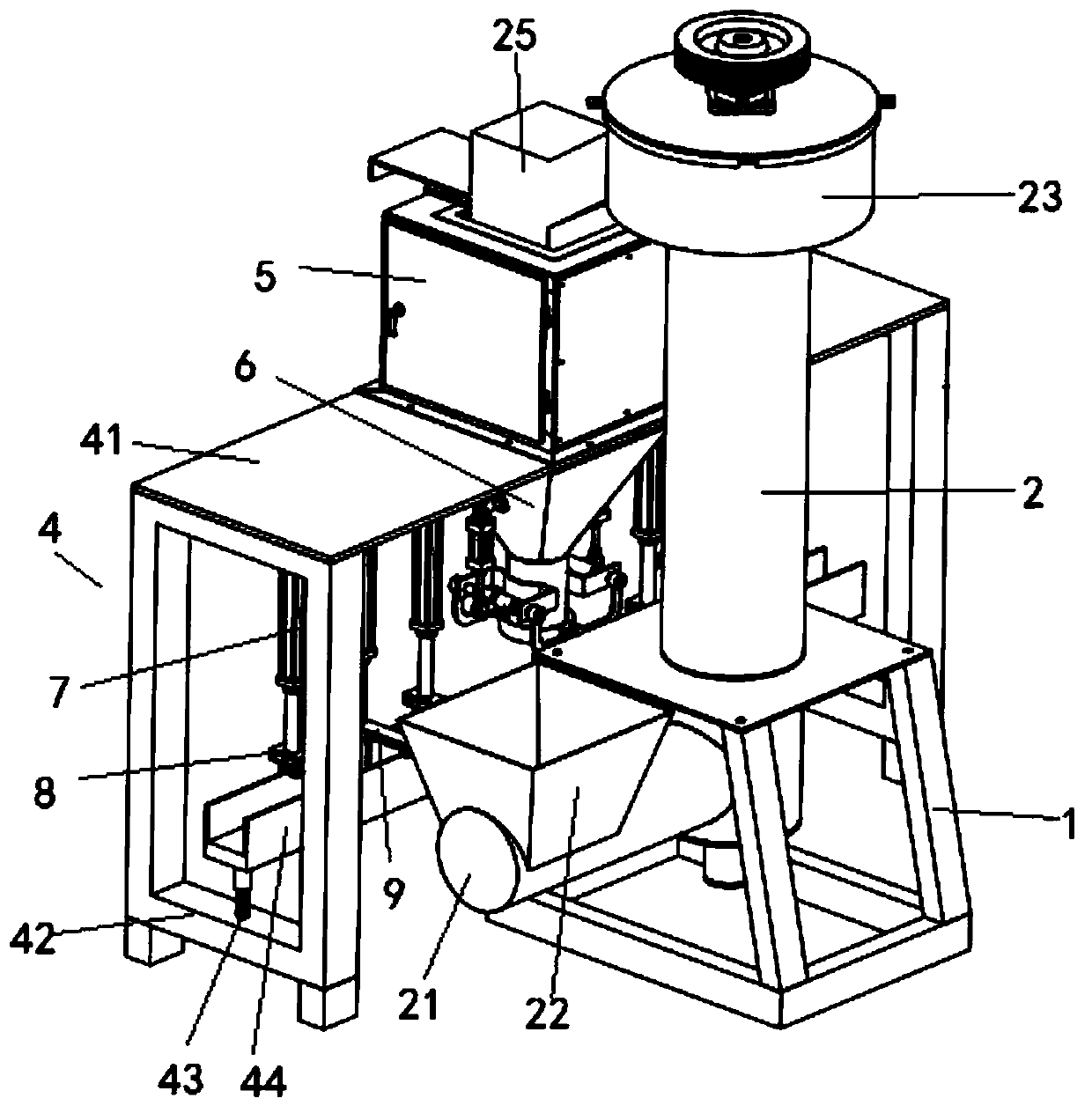

[0038] Such as figure 1 As shown, the feeding, filling and bagging device includes a lifting and feeding mechanism and a filling and sealing mechanism, through which the prepared particles are lifted from the bottom and transferred to the filling and sealing mechanism, and then sealed;

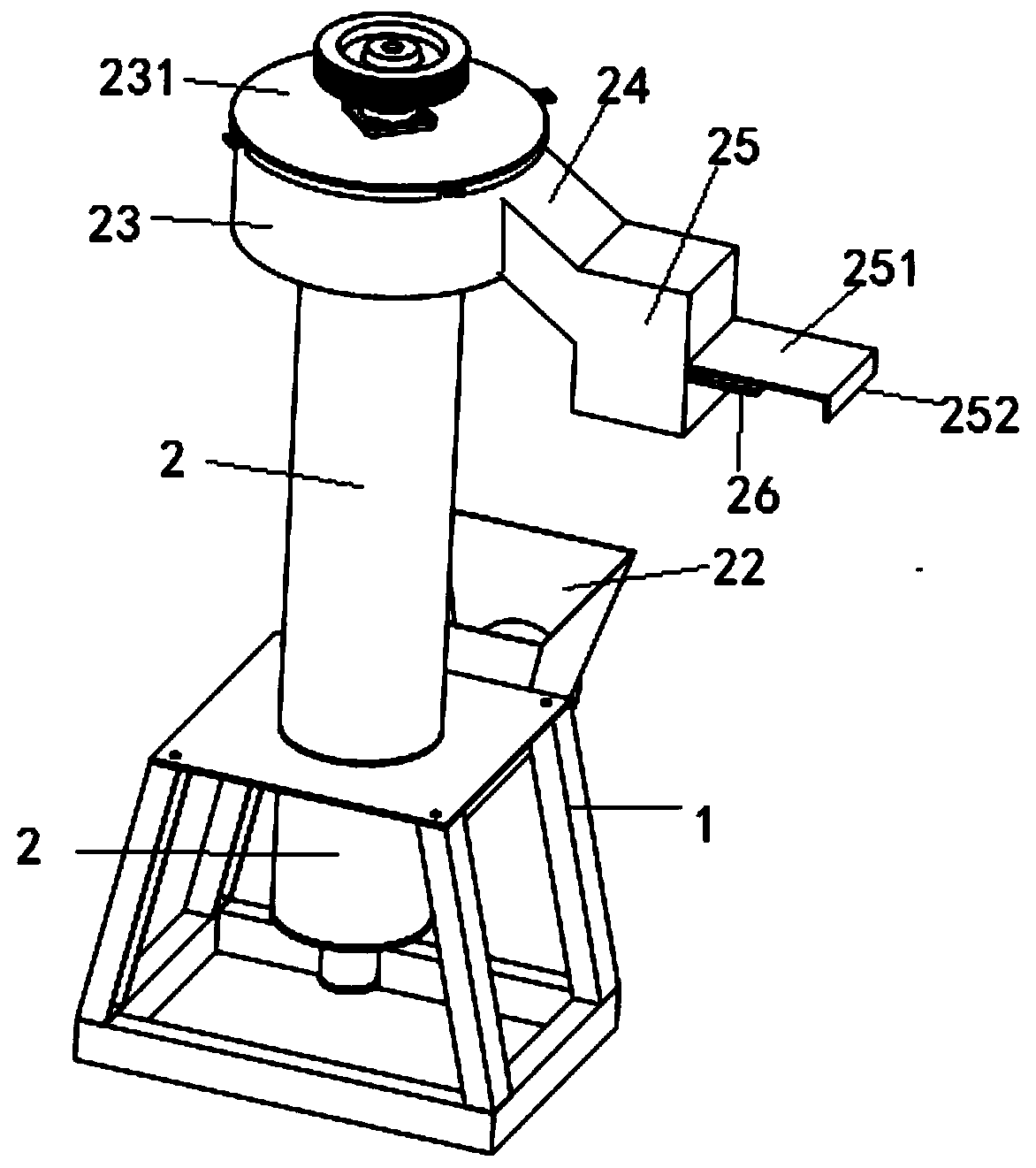

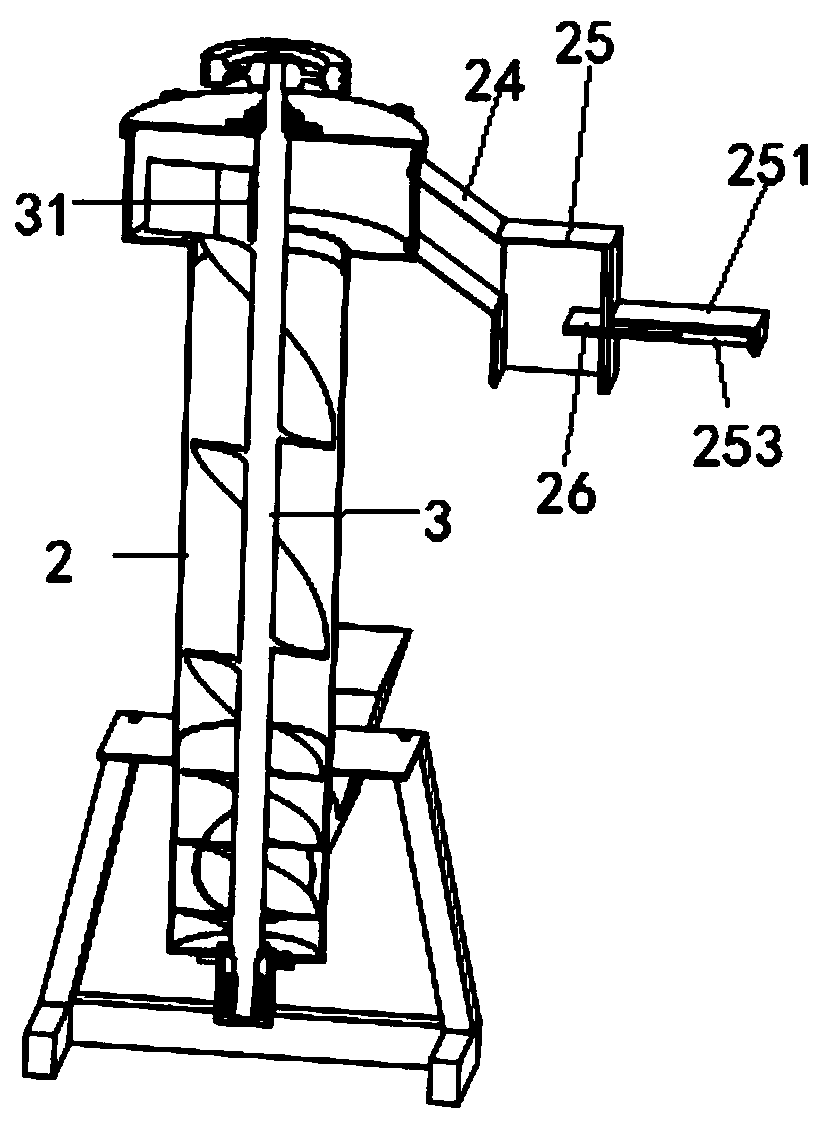

[0039]Wherein the lifting feeding mechanism includes installing the bottom frame 1, and the surface of the bottom frame 1 is installed with a feeding conveying cylinder 2, and the lower end of the side wall of the feeding conveying cylinder 2 is integrally equipped with a feeding cylinder 21, and the feeding cylinder 21 is arranged obliquely, and The feeding cylinder 21 is connected with the feeding conveying cylinder 2, the upper side wall of the feeding conveying cylinder 2 is provided with a feeding hopper 22, the top of the feeding conveying cylinder 2 is equipped with a discharge buffer cylinder 23, and the top of the discharge buffer cylinder 23 A top plate 231 is provided, and a dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com