Garbage drying treatment method and application thereof

A treatment method and technology for waste drying, which are applied in special forms of dry distillation, preparation of liquid hydrocarbon mixtures, biofuels, etc. The effect of saving energy and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

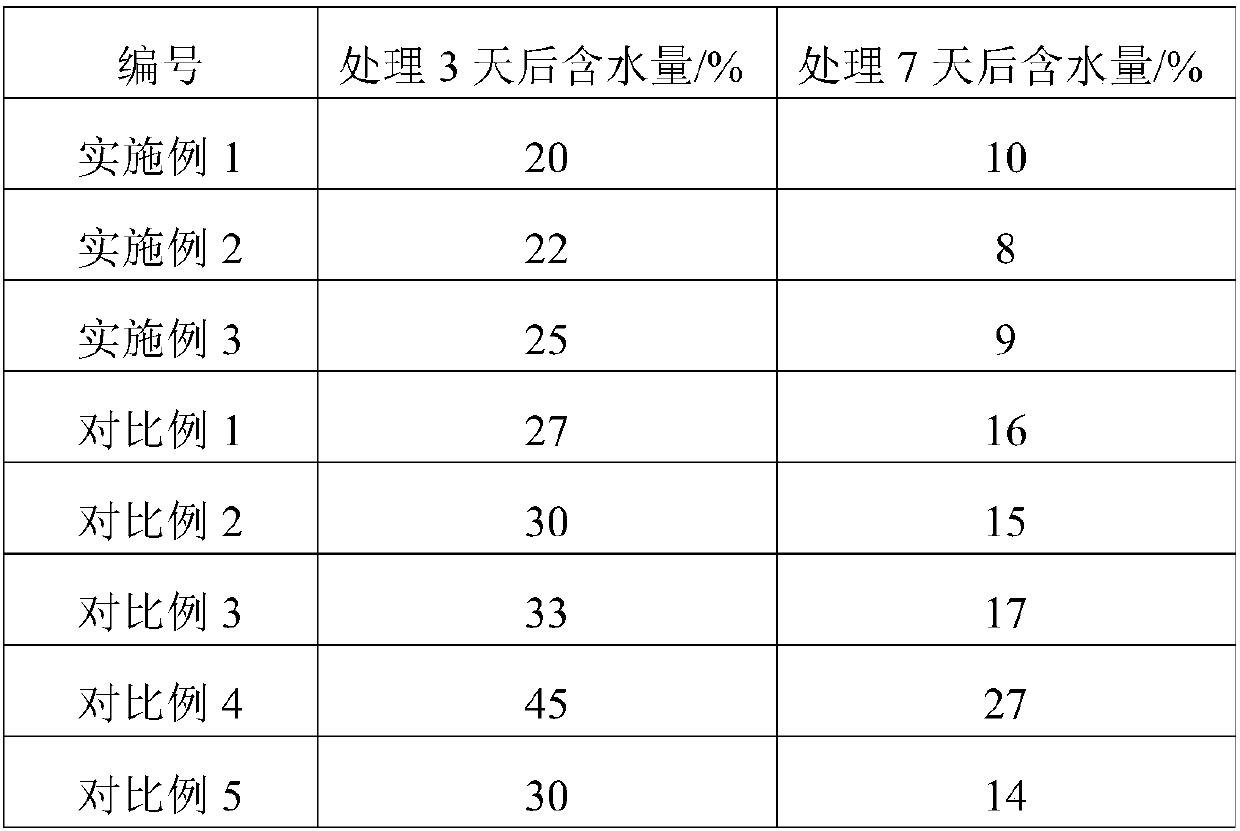

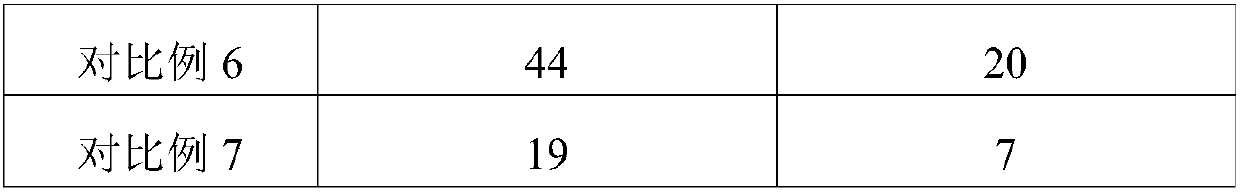

Examples

Embodiment 1

[0031] A method for dry treatment of garbage, the steps comprising:

[0032] (1) Pile the garbage in the greenhouse, and seal the greenhouse so that the moisture inside the garbage evaporates to the surface and reaches a saturated state;

[0033] (2) reduce the surface humidity of the garbage, so that the humidity on the surface of the garbage changes from the saturated state of step (1) to the unsaturated state;

[0034] (3) Repeat steps (1) and (2) until the moisture content in the garbage is reduced to 40-60%, add fermentation aids to the garbage, and continue to dry the garbage after turning over until the moisture content reaches the standard.

[0035] The greenhouse in step (1) is a film greenhouse, and the color of the film is black.

[0036] The method for reducing the surface humidity of the garbage in the step (2) is drying with waste heat of the garbage pyrolysis and carbonization system.

[0037] The waste heat drying method is as follows: the waste heat of the w...

Embodiment 2

[0042] A method for dry treatment of garbage, the steps comprising:

[0043] (1) Pile the garbage in the greenhouse, and seal the greenhouse so that the moisture inside the garbage evaporates to the surface and reaches a saturated state;

[0044] (2) reduce the surface humidity of the garbage, so that the humidity on the surface of the garbage changes from the saturated state of step (1) to the unsaturated state;

[0045] (3) Repeat steps (1) and (2) until the moisture content in the garbage is reduced to 40-60%, add fermentation aids to the garbage, and continue to dry the garbage after turning over until the moisture content reaches the standard.

[0046] The greenhouse in step (1) is a film greenhouse, and the color of the film is black.

[0047] The method for reducing the surface humidity of the garbage in the step (2) is drying with waste heat of the garbage pyrolysis and carbonization system.

[0048] The waste heat drying method is as follows: the waste heat of the w...

Embodiment 3

[0053] A method for dry treatment of garbage, the steps comprising:

[0054] (1) Pile the garbage in the greenhouse, and seal the greenhouse so that the moisture inside the garbage evaporates to the surface and reaches a saturated state;

[0055] (2) reduce the surface humidity of the garbage, so that the humidity on the surface of the garbage changes from the saturated state of step (1) to the unsaturated state;

[0056] (3) Repeat steps (1) and (2) until the moisture content in the garbage is reduced to 40-60%, add fermentation aids to the garbage, and continue to dry the garbage after turning over until the moisture content reaches the standard.

[0057] The greenhouse in step (1) is a film greenhouse, and the color of the film is black.

[0058] The method for reducing the surface humidity of the garbage in the step (2) is drying with waste heat of the garbage pyrolysis and carbonization system.

[0059] The waste heat drying method is as follows: the waste heat of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com