Method for improving surface quality of plastic metal electron back scattering diffraction sample

A technology of electron backscattering and surface quality, which is applied to the use of wave/particle radiation for material analysis, measuring devices, instruments, etc., can solve the problems of low quality of diffraction patterns and difficulty in obtaining experimental results, etc., and improve the solvability rate of samples , improve the surface quality of the sample, and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] like figure 1 , figure 2 Shown, a kind of method that improves plastic metal electron backscatter diffraction sample surface quality, described method comprises the following steps:

[0023] Step 1: Sample preparation: Obtain a cylindrical sample along the radial direction of the metal;

[0024] Step 2: Grinding: surface grinding treatment is performed on the radial section of the sample obtained in Step 1;

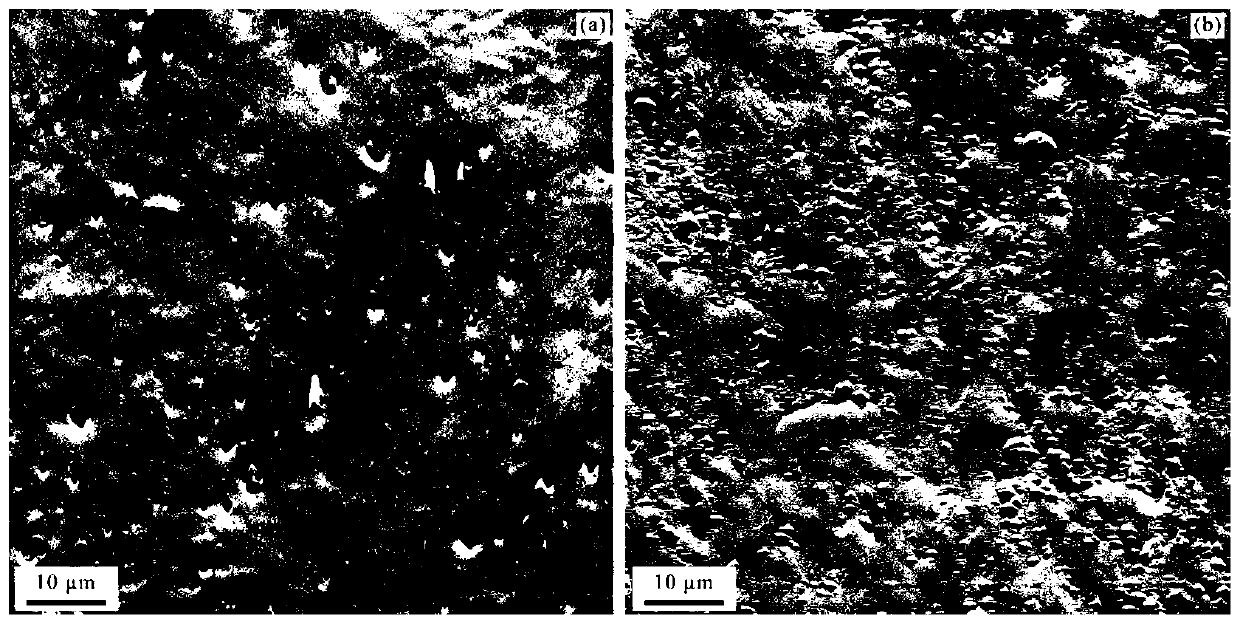

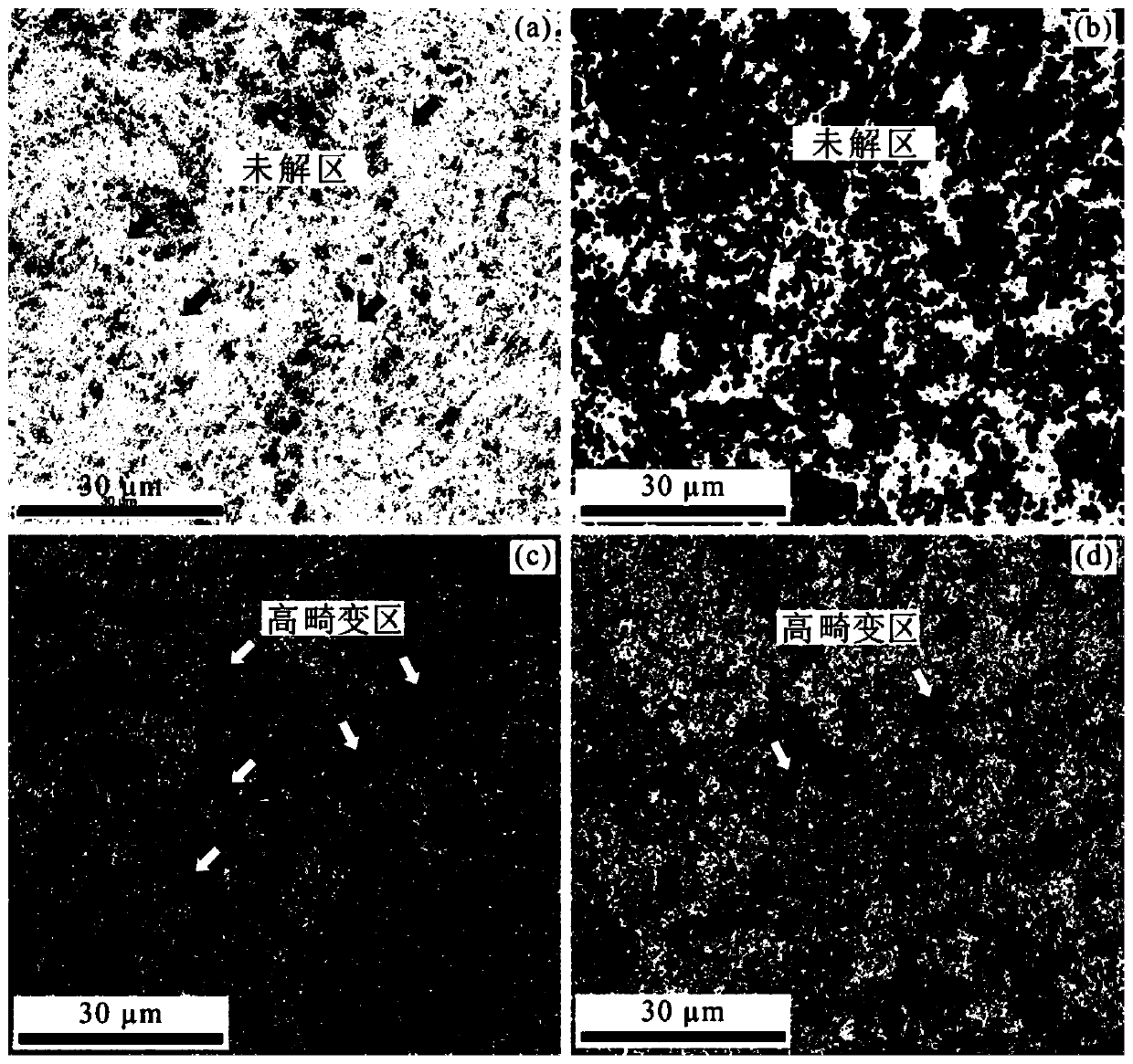

[0025] Step 3: mechanical polishing: perform surface mechanical polishing on the sample polished in step 2;

[0026] Step 4: electrolytic polishing: the sample after the mechanical polishing in step 3 is subjected to surface electrolytic polishing;

[0027] Step 5: Ion etching: the surface ion etching treatment is performed on the sample after the depolishing treatment in step 4.

[0028] The plastic metal surface is treated by sample preparation, grinding, mechanical polishing, electrolytic polishing, and ion etching, and the sample in step one is prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com