Processing equipment and processing method for grounding rod

A technology for processing equipment and grounding rods, which is applied in the field of processing equipment for grounding rods, can solve the problems of low corrosion resistance, insufficient corrosion resistance of grounding rods, and easy wear, and achieve high processing efficiency, improved corrosion resistance, and convenience The effect of maintenance and repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

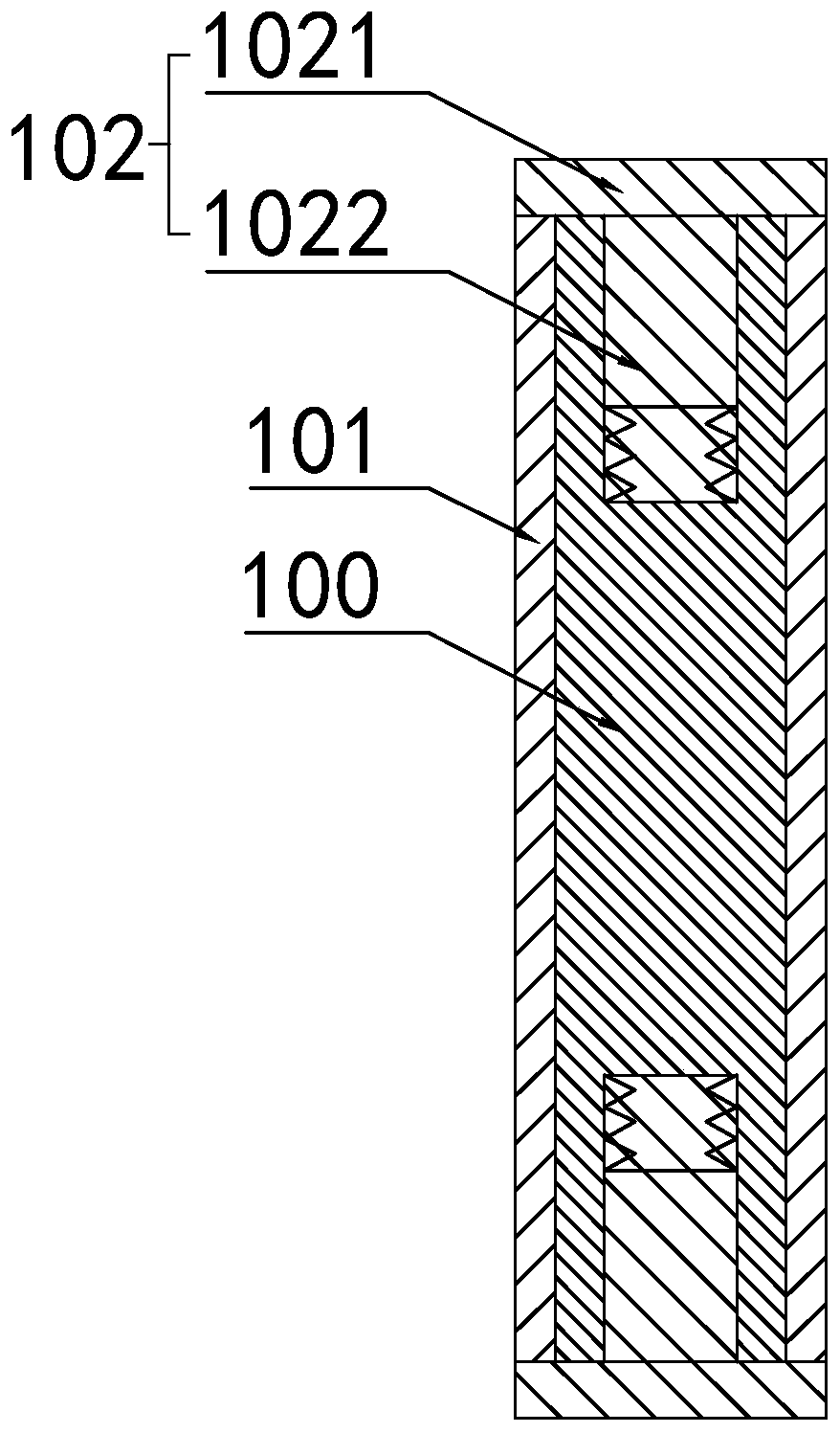

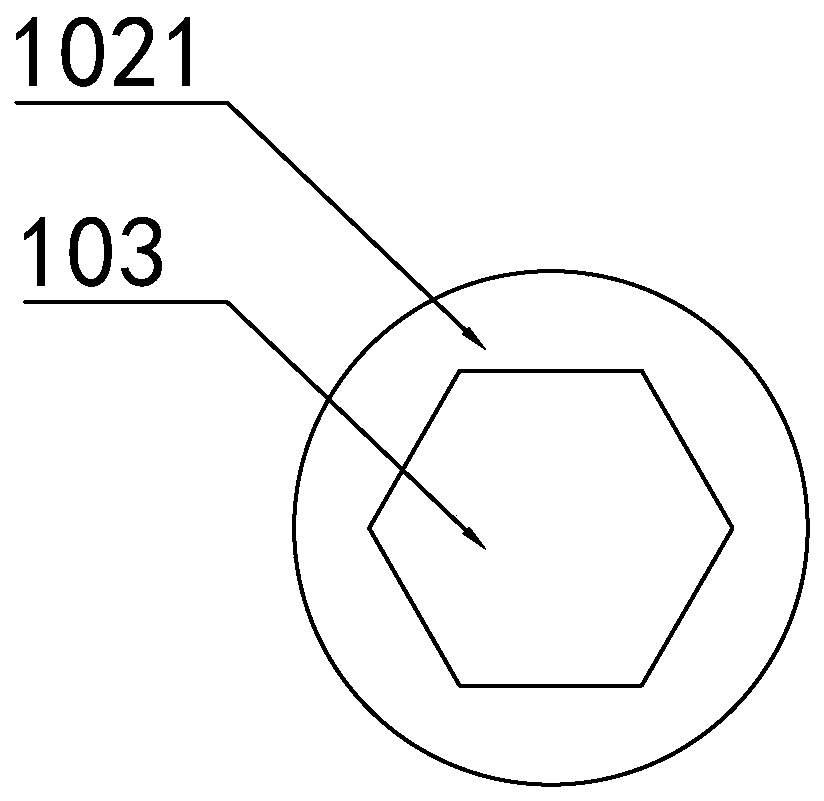

[0046] Such as Figure 1-Figure 2 As shown, the present invention discloses a grounding rod. In a specific embodiment of the present invention, it includes a steel core 100, a hollow copper sleeve 101 and two copper seats 102 installed at both ends of the copper sleeve 101; 102 includes a copper cover plate 1021 and a cylindrical mandrel 1022 whose outer diameter matches the inner diameter of the copper sleeve 101; One end of the steel core 100 is fixedly connected, both ends of the steel core 100 are provided with internal threaded holes that are compatible with the cylindrical mandrel 1022, and the steel core 100 is set inside the copper sleeve 101 and interferes with the copper sleeve 101 Fitting; the cylindrical mandrel 1022 penetrates along one end of the copper casing 101 and is threadedly connected with the steel core 100; the copper casing 101 and the copper cover 1021 are fixed by welding; the copper cover 1021 A hexagonal groove 103 is provided on the outer wall of ...

Embodiment 2

[0049] In addition, the present invention also provides a processing method for grounding rods, a processing method for grounding rods, comprising the following steps:

[0050] S1 Turning: First, the raw material steel core and copper sleeve are turned and cut off to control the length and outer diameter of the steel core and copper sleeve;

[0051] S2 polishing: polishing the outer wall of the copper sleeve and steel core by a polishing machine;

[0052] S3 chamfering: chamfering both ends of the steel core;

[0053] S4 Stamping: Press the steel core into the copper sleeve through the stamping machine and the supporting abrasive tools;

[0054] S5 first socket spot welding: the first copper seat of the steel core is socketed on the copper sleeve through the socket machine and then welded;

[0055] S6 second socket spot welding: use socket machine to socket the second copper seat on the copper sleeve and perform welding;

[0056] S7 Packing: pack the processed copper casing...

Embodiment 3

[0059] In addition, if Figure 3-Figure 13 As shown, the present invention also provides a processing equipment for ground rods. In the specific embodiment of the present invention, according to the processing method, it sequentially includes a lathe 1, a polishing machine 2, a chamfering machine 3, a stamping mechanism 4, a socketing machine 5 and Packer6.

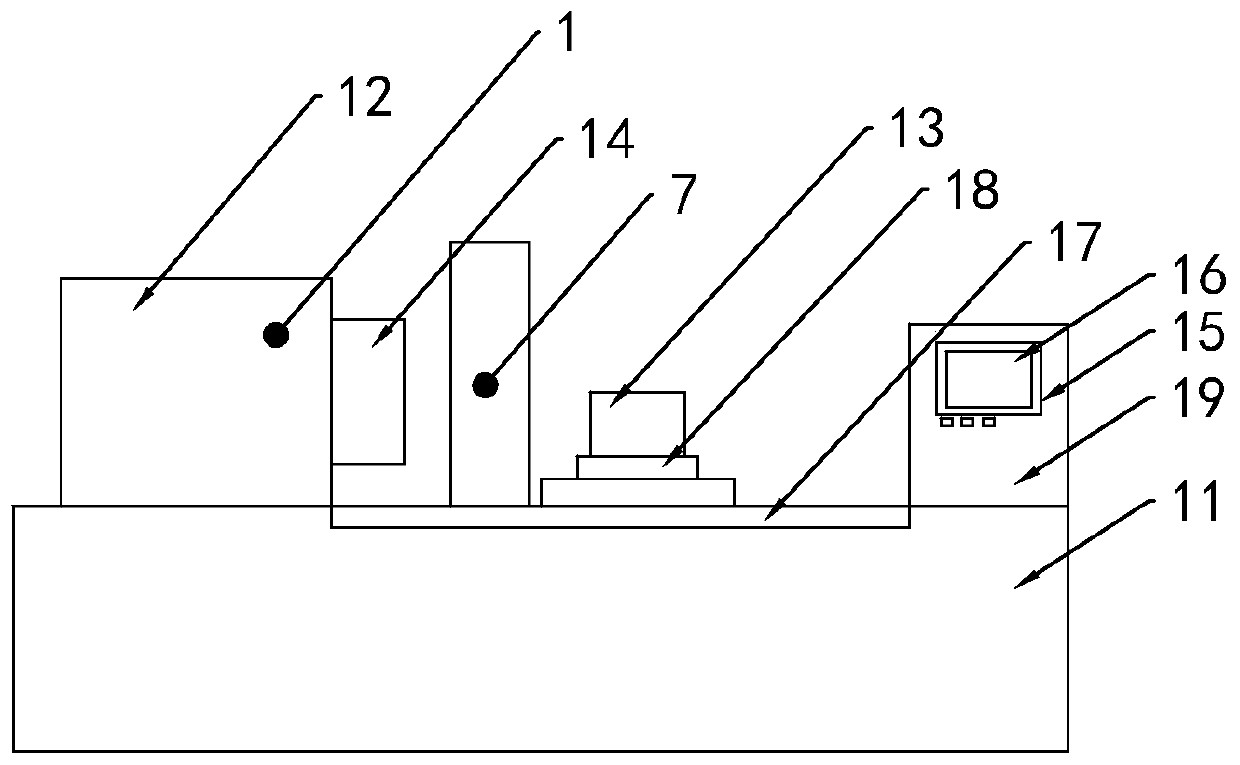

[0060] In a specific embodiment of the present invention, the lathe 1 includes a bed 11, a headstock 12, a tool rest 13, a chuck 14 installed on the headstock 12, a numerical control machining system 15, and a control panel 16; the bed 11 The upper 11 is provided with a guide rail 17; the tool rest 13 slides horizontally and vertically on the bed 11 through the feed mechanism 18; the feed mechanism 18 is electrically connected to the numerical control machining system 15; It is fixedly installed on the bed 11 and electrically connected with the numerical control machining system 14 .

[0061] In the specific embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com