Preparation method and application of metal-organic framework compound electrocatalyst

A metal-organic framework, compound electrotechnology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve excellent cycle stability, accelerated kinetics, good The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

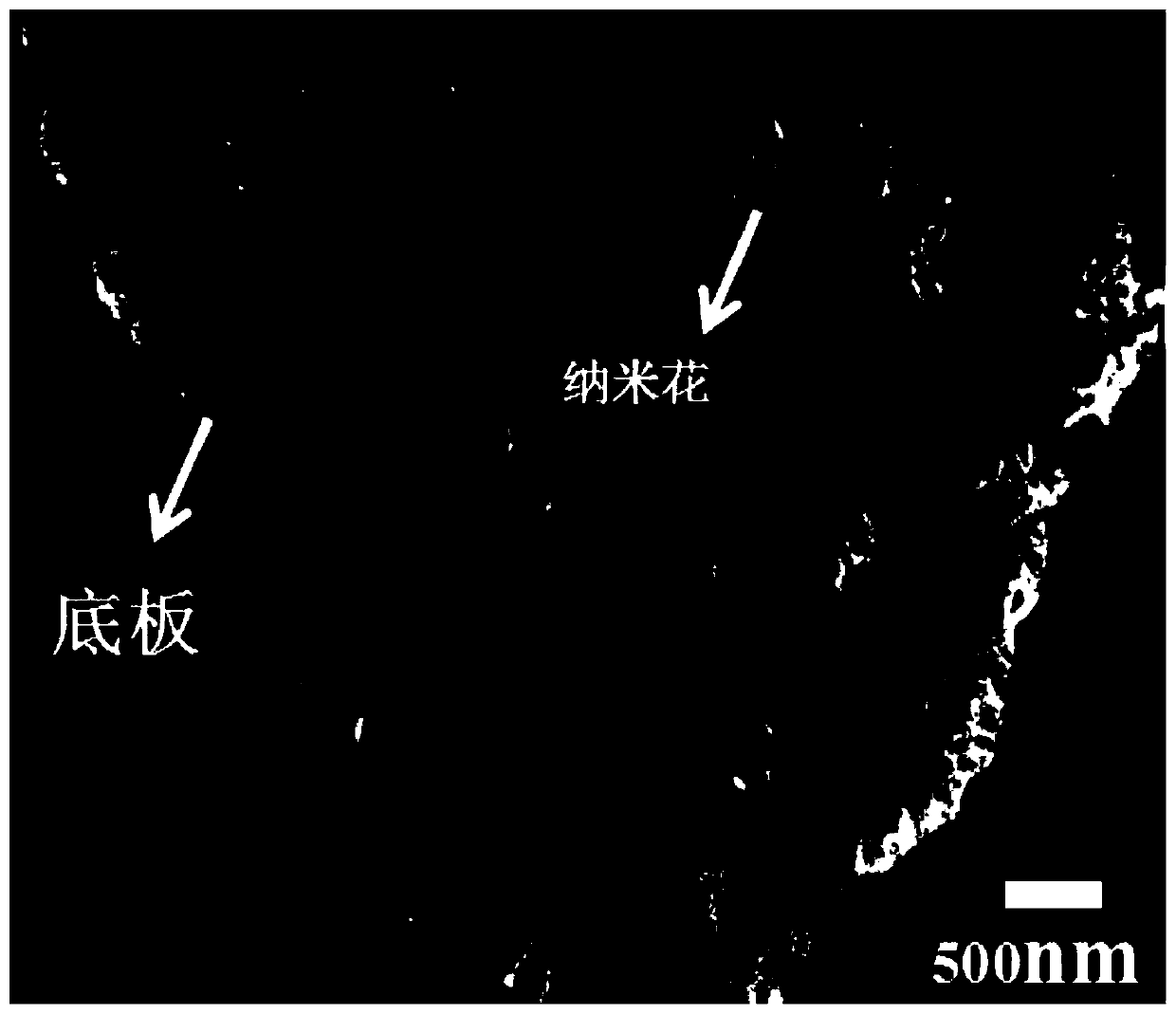

[0042] Example 1: Preparation of three-dimensional self-supporting metal organic framework compound FeNi-MOF / NF

[0043] (1) According to 0.1802g FeCl 3 ·6H 2 O and 0.0969g Ni(NO 3 )2·6H 2 O, be dissolved in the methyl alcohol of 7mL and obtain A solution, 0.1501g tartaric acid is dissolved in the methanol of 7mL and obtain B solution;

[0044] (2) Add solution B to solution A, adjust the pH of the solution to 3 with 1M NaOH methanol solution, and transfer it to a 20mL reaction kettle after stirring evenly;

[0045] (3) Wash the 1×2cm 2 Put the foamed nickel into the reactor vertically, put it in an oven at 130°C for 7 hours, and cool it naturally;

[0046] (4) rinse the foamed nickel after the reaction with ethanol, and vacuum-dry at 60° C.;

[0047] (5) Electrochemical test: in a three-electrode system (the electrode of the metal organic framework compound FeNi-MOF / NF prepared in step (4) is used as a working electrode, the silver / silver chloride electrode is used as a r...

Embodiment 2

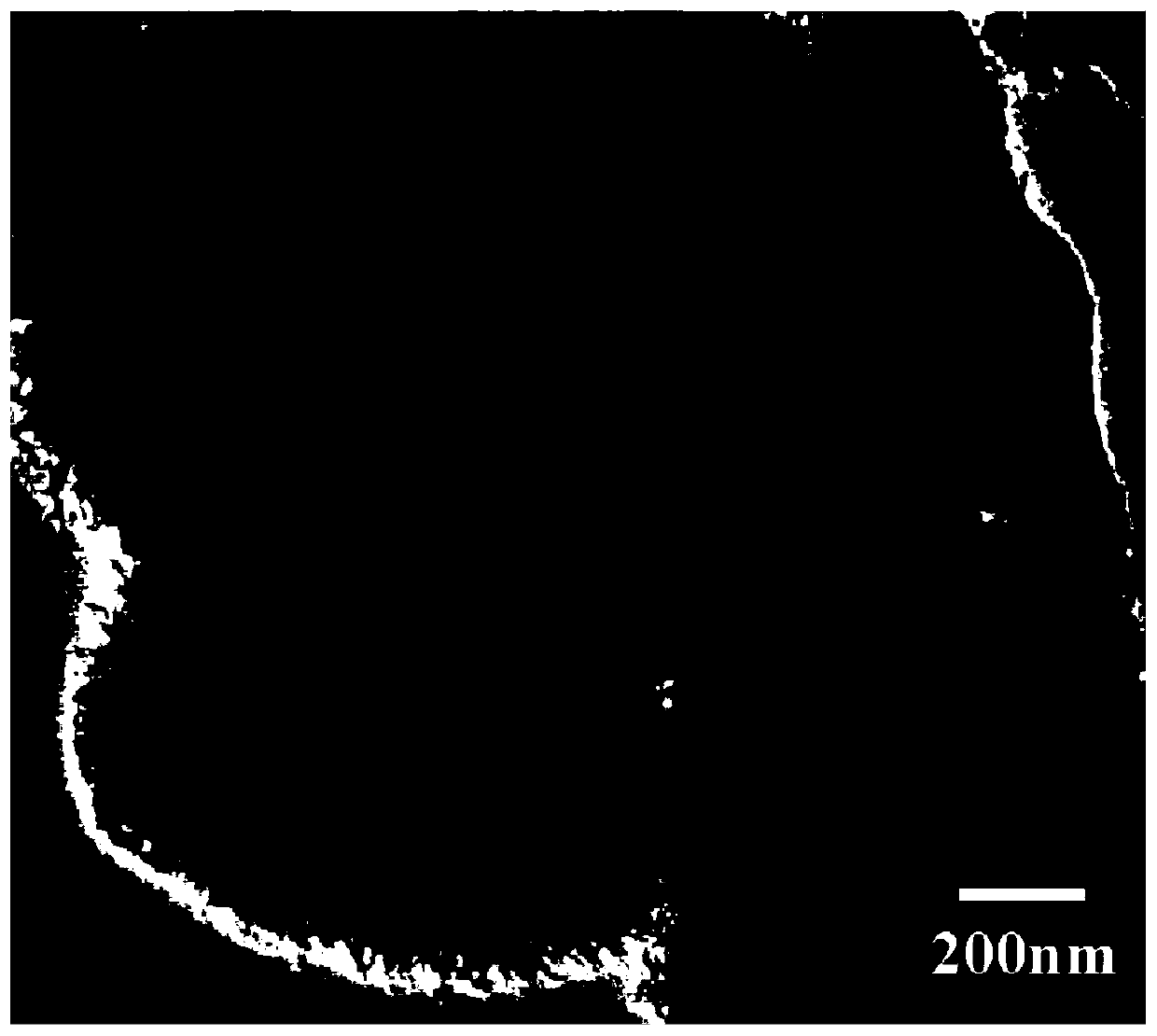

[0048] Example 2: Preparation of three-dimensional self-supporting metal organic framework compounds Fe-MOF / NF and Ni-MOF / NF

[0049] (1) According to 0.1802g FeCl 3 ·6H 2 O(0.0969g Ni(NO 3 ) 2 ·6H 2 0) be dissolved in the methyl alcohol of 7mL and obtain A solution, and 0.1501g tartaric acid is dissolved in the methanol of 7mL and obtain B solution;

[0050] (2) Add solution B to solution A, adjust the pH of the solution to 3 with NaOH methanol solution, and transfer it to a 20mL reaction kettle after stirring evenly;

[0051] (3) Wash the 1x2cm with 1M HCl, ethanol, deionized water 2 Put the foamed nickel into the reactor vertically, put it in an oven at 130°C for 7 hours, and cool it naturally;

[0052] (4) Rinse the reacted nickel foam with ethanol, and vacuum-dry at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com