Method for making wetland by backfilling sludge

A silt and wetland technology, applied in the fields of filling water and building land, separation methods, chemical instruments and methods, etc., can solve the problems of multiple human and material resources, sedimentation of silt, etc., and achieve the effect of improving the ecological environment, improving water quality, and saving human and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

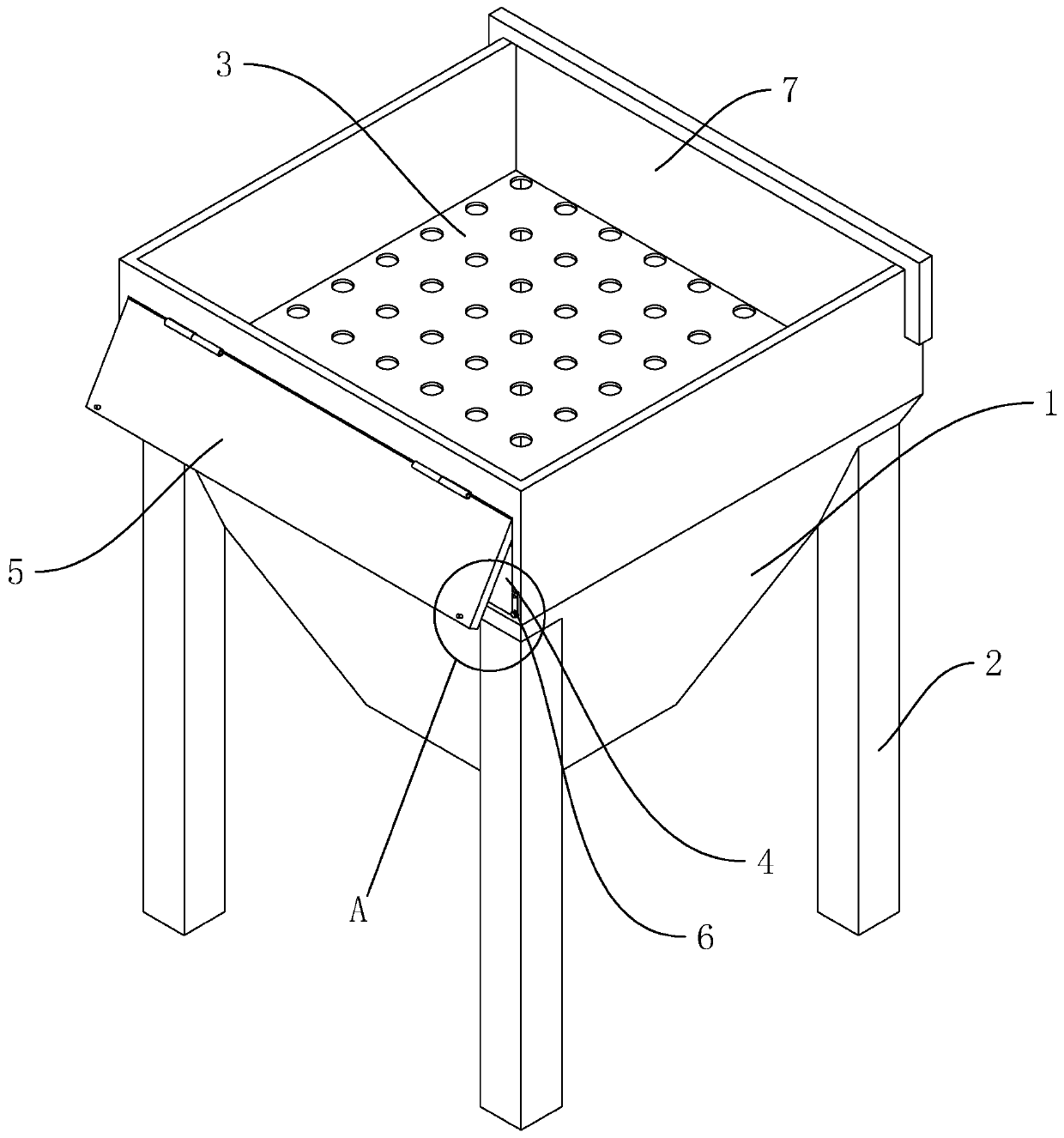

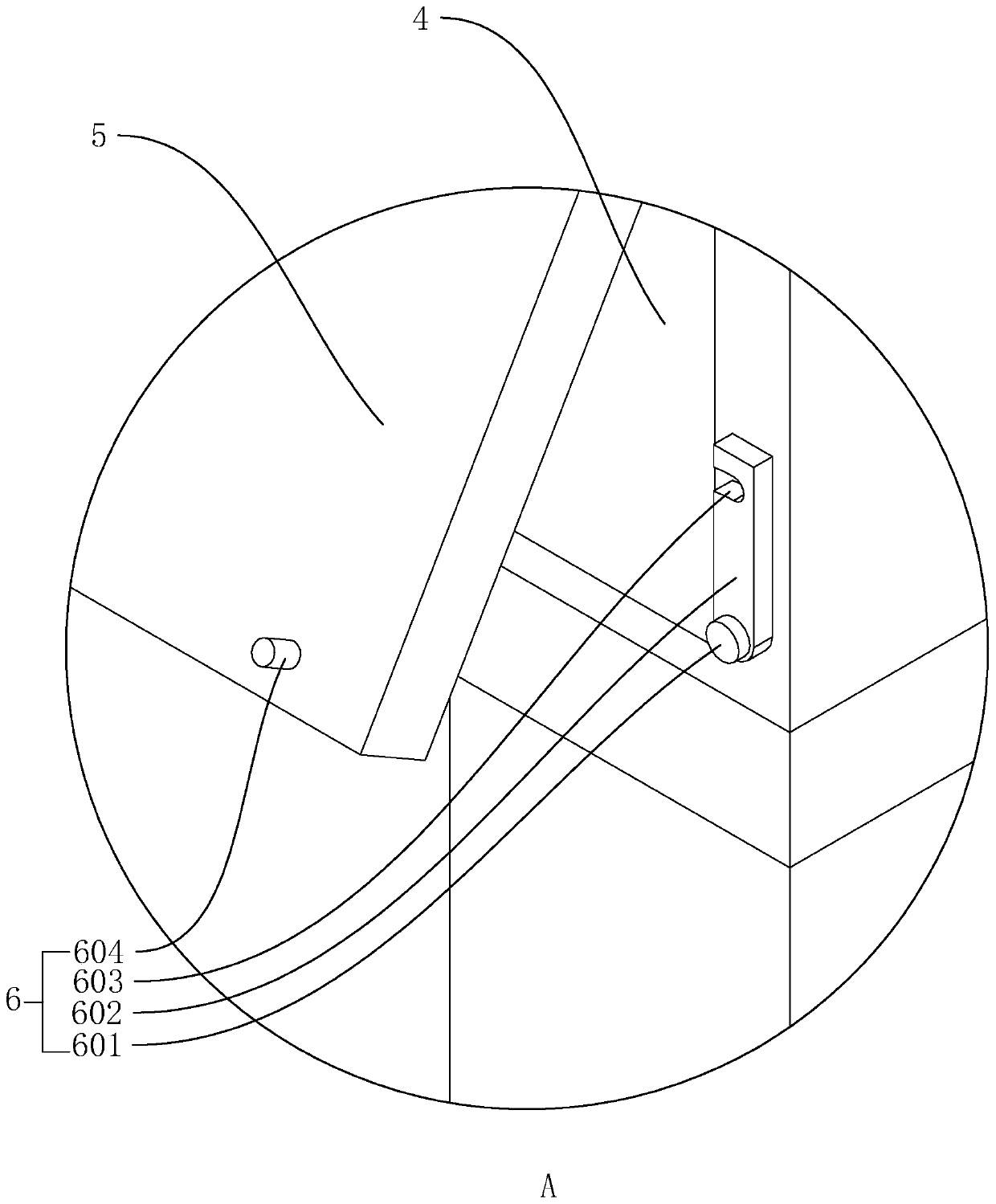

[0040] The present invention will be further described in detail below with reference to the accompanying drawings.

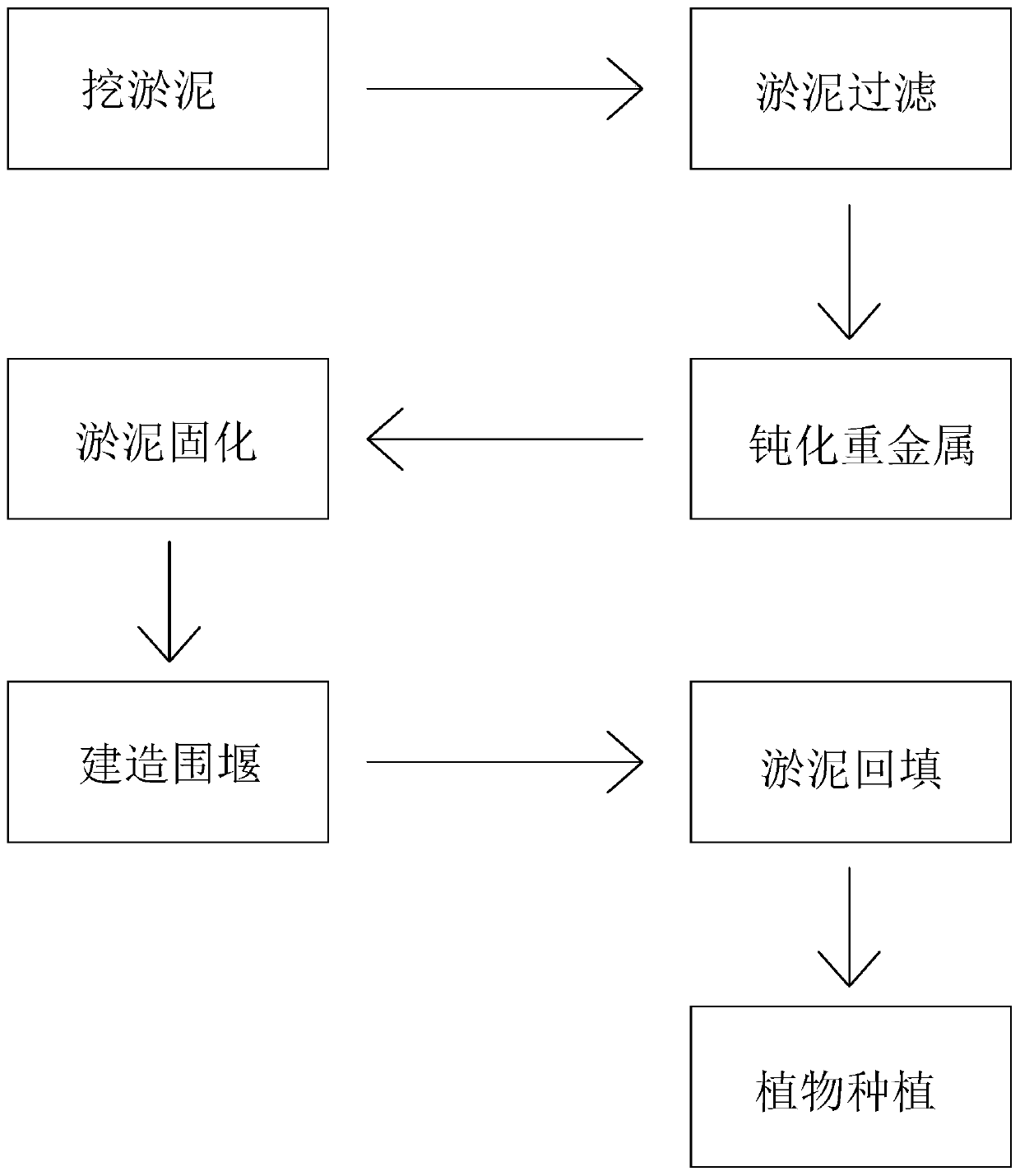

[0041] Reference figure 1 , Is a method for making wetland through silt backfilling disclosed in the present invention, including the following steps:

[0042] Step 1: Dig the silt, use the dredging equipment to dig out the silt from the lake and place it on the shore;

[0043] Step 2: Sludge filtration. The sludge is sent to the filter device for filtration, and the large solid debris is separated from the sludge through filtration;

[0044] Step 3: Passivate heavy metals, add passivating agent to the sludge, increase the pH value of the sludge, convert heavy metals into hydroxides and other precipitation, to achieve the effect of inactivating heavy metals and killing pathogens;

[0045] Step 4: The sludge is solidified, and a solidifying agent is added to the sludge to quickly solidify the sludge;

[0046] Step 5: Construct a cofferdam, construct a cofferdam on the edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com