Anti-efflorescence inorganic artificial stone floor tile

A stone floor tile and anti-efflorescence technology, applied in the field of inorganic artificial stone, can solve the problems of easy breakage, short life cycle, and inability to achieve long-term use, so as to achieve the effect of ensuring beauty and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

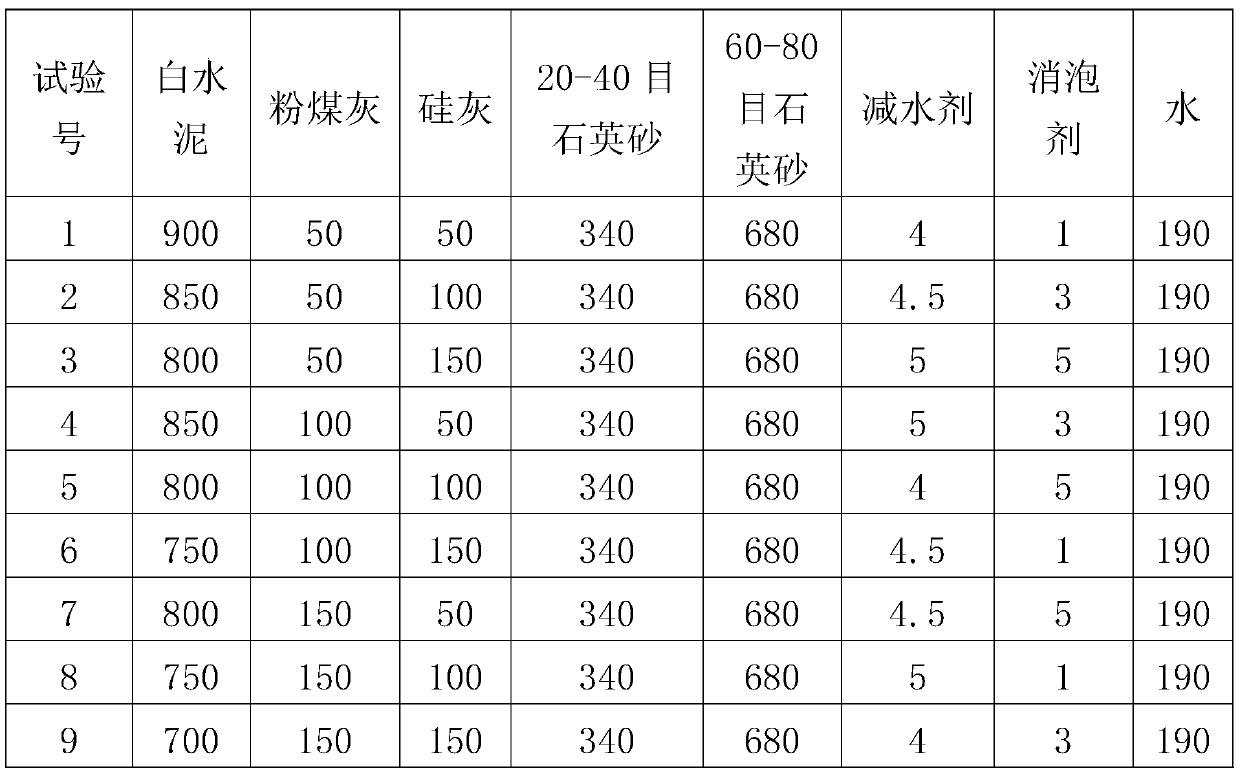

[0041] Mix the main mixture with water in different proportions; choose 52.5 white Portland cement for cement; choose secondary fly ash for fly ash; choose quartz sand of 20-40 mesh and 60-80 mesh; water reducer Polycarboxylate is selected; the defoamer is polyether defoamer. All the test blocks were cured in the natural environment for 28 days.

[0042]

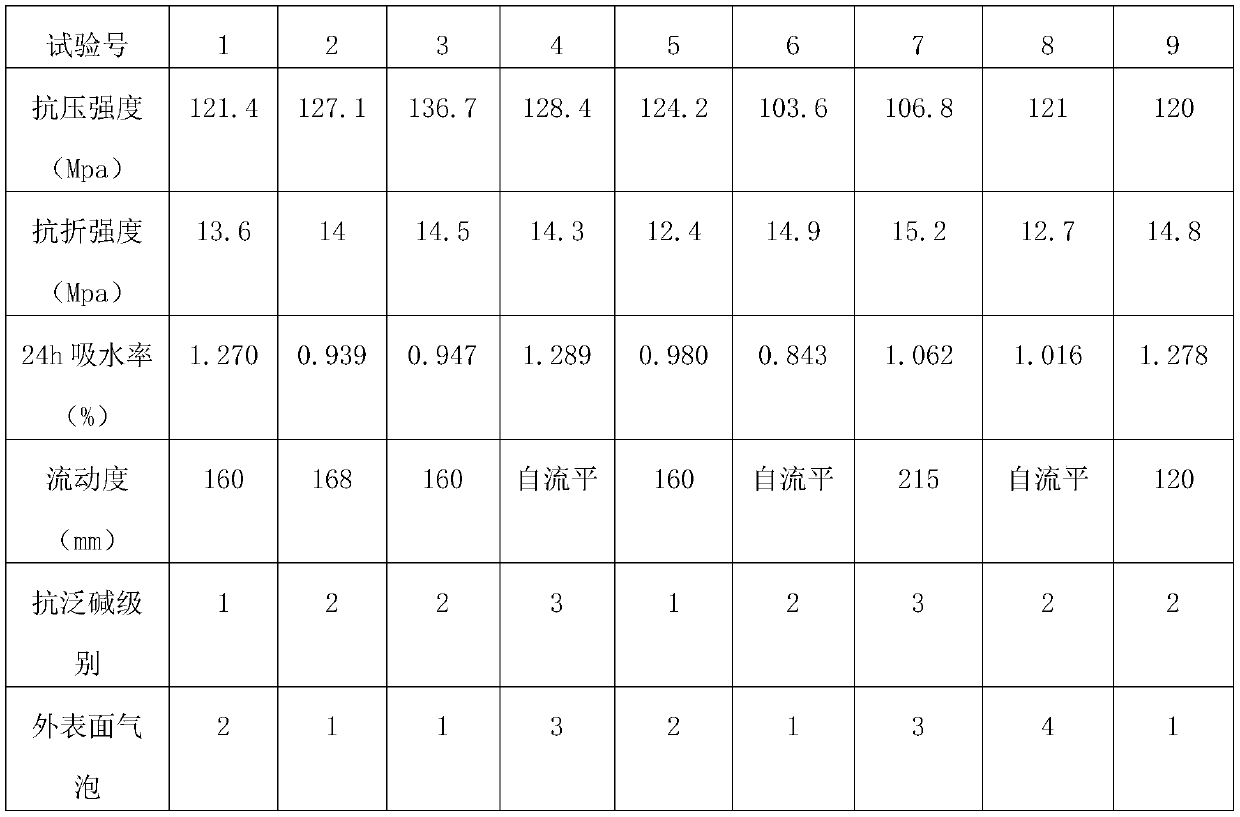

[0043] The above examples were subjected to mechanical properties, fluidity, water absorption, anti-efflorescence test and surface air bubbles to obtain Table 2.

[0044]

[0045] illustrate:

[0046] 1. Comparing the 9 sets of test results of the orthogonal test, it is difficult to find the influence of various factors on its compressive strength, flexural strength, water absorption, fluidity, efflorescence resistance level and outer surface bubbles. Therefore, it is necessary to conduct range and variance analysis on the orthogonal test data in order to fully understand the influence of various factors on various p...

Embodiment B

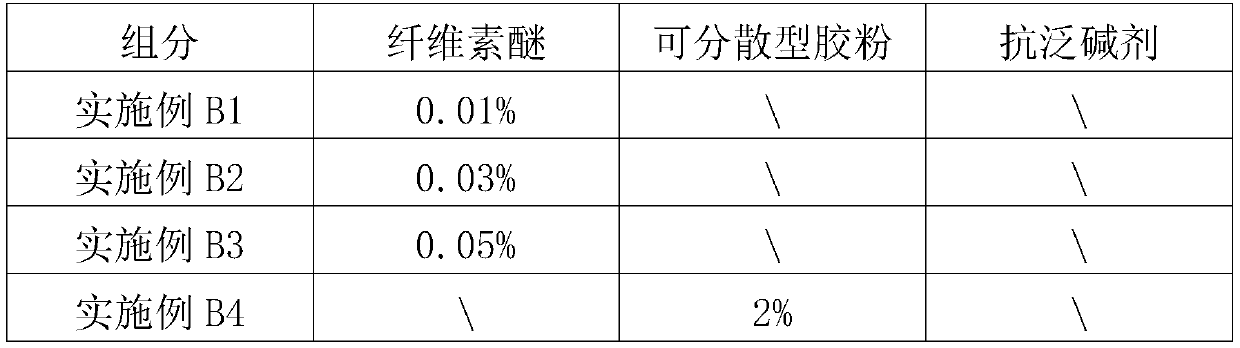

[0059] Select embodiment A4 (the 4th group experiment in embodiment A, hereinafter abbreviate) compound ratio as the basic formula of this example B, but add any admixture in A4 compound ratio as embodiment B1-B9, as table 3.

[0060]

[0061]

[0062] The above-mentioned Example B was tested for its mechanical properties and anti-efflorescence performance, and Table 4 was prepared.

[0063] components Anti-pantherine grade Compressive strength (Mpa) Flexural strength (Mpa) Example B1 3 119.2 14.1 Example B2 3 108.8 13.2 Example B3 3 99.4 12.8 Example B4 3 124.3 14.4 Example B5 3 119.6 15.2 Example B6 4 112.8 14.8 Example B7 3 119.8 14.5 Example B8 4 127.5 14.7 Example B9 3 125.3 13.9

[0064] illustrate:

[0065] 1. Instances B1-B3 were mixed with different amounts of cellulose ether. From the results of the anti-efflorescence test, it can be seen that the incorporation of cellul...

Embodiment C

[0069] Continue to select the A4 mix ratio as the basic formula of C in this example, and mix the dispersible rubber powder and the anti-efflorescence agent in the A4 mix ratio. As examples C1-C9, as in Table 5.

[0070] components Dispersible rubber powder / anti-efflorescence agent Example C1 2% / 0.1% Example C2 2% / 0.2% Example C3 2% / 0.3% Example C4 3% / 0.1% Example C5 3% / 0.2% Example C6 3% / 0.3% Example C7 4% / 0.1% Example C8 4% / 0.2% Example C9 4% / 0.3%

[0071] The above-mentioned Example C was tested for its mechanical properties and anti-efflorescence performance, and Table 6 was prepared.

[0072]

[0073]

[0074] illustrate:

[0075] 1. From the data in the table, it can be known that compounding dispersible rubber powder and anti-pantherine agent generally improves the anti-pantherine grade of the floor tiles, and the anti-pantherine grade of Example B8 has reached the level of anti-pantherine leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com