Hydrophilic antifouling coating structure with antibacterial property, forming method of hydrophilic antifouling coating structure and measuring equipment

An antifouling and coating technology, applied in antifouling/underwater coatings, coatings, polyester coatings, etc., can solve the problem of harmful bacteria adhesion to the human body, and achieve the effect of inhibiting infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

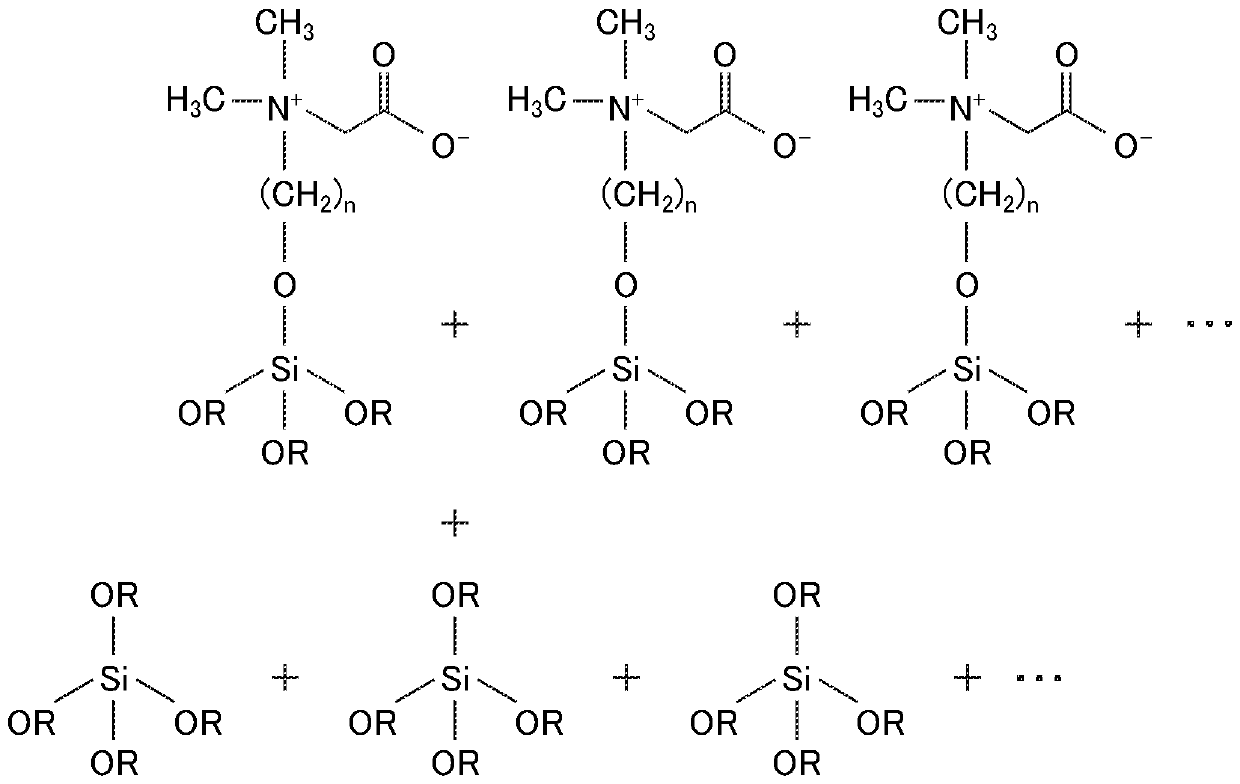

[0062] 1. First embodiment: Two-liquid lamination of glass-like coating layer and betaine structure layer

[0063] (1-1. Composition)

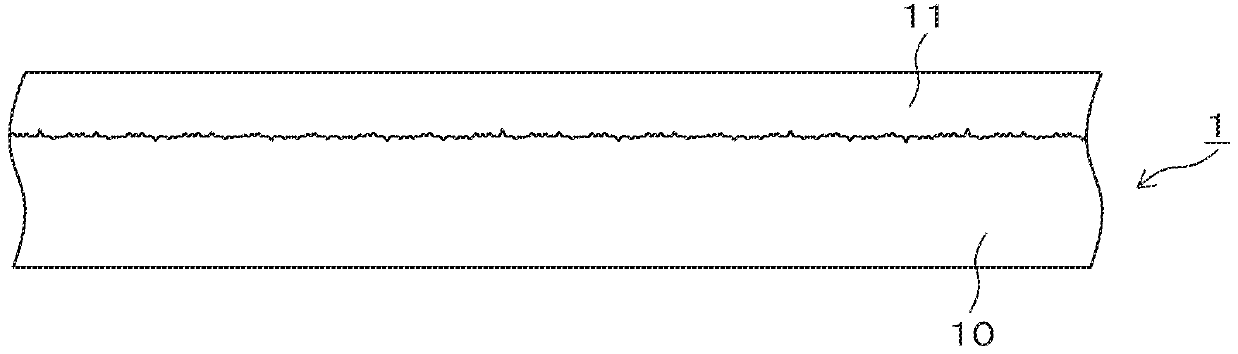

[0064] FIG. 1 shows a hydrophilic antifouling coating structure 1 according to the first embodiment of the present invention. also, Figure 4~7 Shows the chemical state when each layer of the hydrophilic antifouling coating structure 1 is formed.

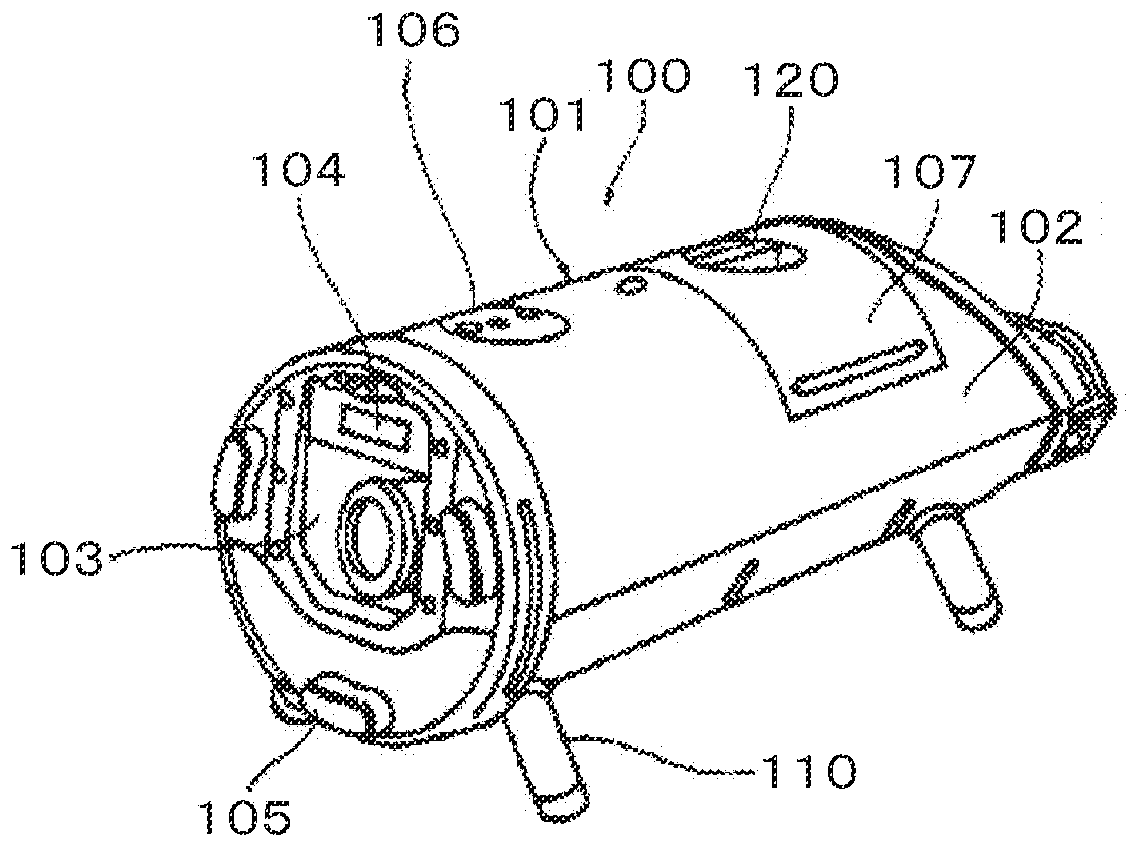

[0065] In FIG. 1( d ), reference numeral 10 is a base material made of resin such as ABS. In the present invention, application to a housing of a measuring device is the main purpose, but is not limited thereto. The measuring equipment includes: a pipe laser device for detecting whether multiple sewer pipes are arranged in a straight line, a rotating laser device for detecting indoor horizontal positions, etc., a GPS (Global Positioning System, Global Positioning System) main body, and a radio wave transmitting and receiving device. Antennas, scanners for detecting terrain information through dig...

no. 1 approach and no. 2 approach

[0100] (First Embodiment and Second Embodiment: Summary, Other Modifications)

[0101] The first embodiment and the second embodiment are particularly effective for resins that have few OH groups on the surface, are difficult to activate the surface, and are difficult to apply hydrophilic coating directly, unlike metals, glass, and the like. Such a resin is not particularly limited, but ABS commonly used in housings of measuring devices and other measuring devices is particularly preferable.

[0102] It should be noted that, in the first embodiment and the second embodiment, in the case where the substrate is rich in OH groups such as metal and glass, no etching components are required, and the OH groups of the glassy coating and the OH groups of the substrate Condensation occurs to chemically bond.

[0103] The glassy coating layer in the first embodiment of the present invention is preferably formed to a thickness of several hundred μm or less. The reason for this is that ...

no. 3 approach

[0114] 3. Third Embodiment: Single-liquid lamination of antifouling layer (paint part and betaine structure part)

[0115] (3-1. Composition)

[0116] Figure 10~11 It shows the chemical state when each layer of the antifouling coating structure 3 according to the third embodiment of the present invention is formed. In this embodiment, Figure 11 The reference numeral 30 may be the same resin substrate as that of the first embodiment. In addition, the reference numeral 30 may be a molded structure, and the single-liquid coating of the paint and the betaine structure part may be directly performed on these substrates. to set the antifouling layer.

[0117] In this embodiment, unlike the first embodiment and the second embodiment, it is characterized in that a glass-like coating is not provided, but a silver compound and A betaine structure that forms paints and hydrophilic antifouling coatings by one-liquid coating.

[0118] like Figure 11As shown, an antifouling layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com