Manufacturing method of high-assignment secondary over-dyed frosted leather

A production method and value-assigning technology, which is applied in dyeing, leather dipping, small leather/big leather/leather/fur treatment, etc., to achieve excellent air permeability, improve the flatness and embossing of the leather surface, and increase the bursting strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

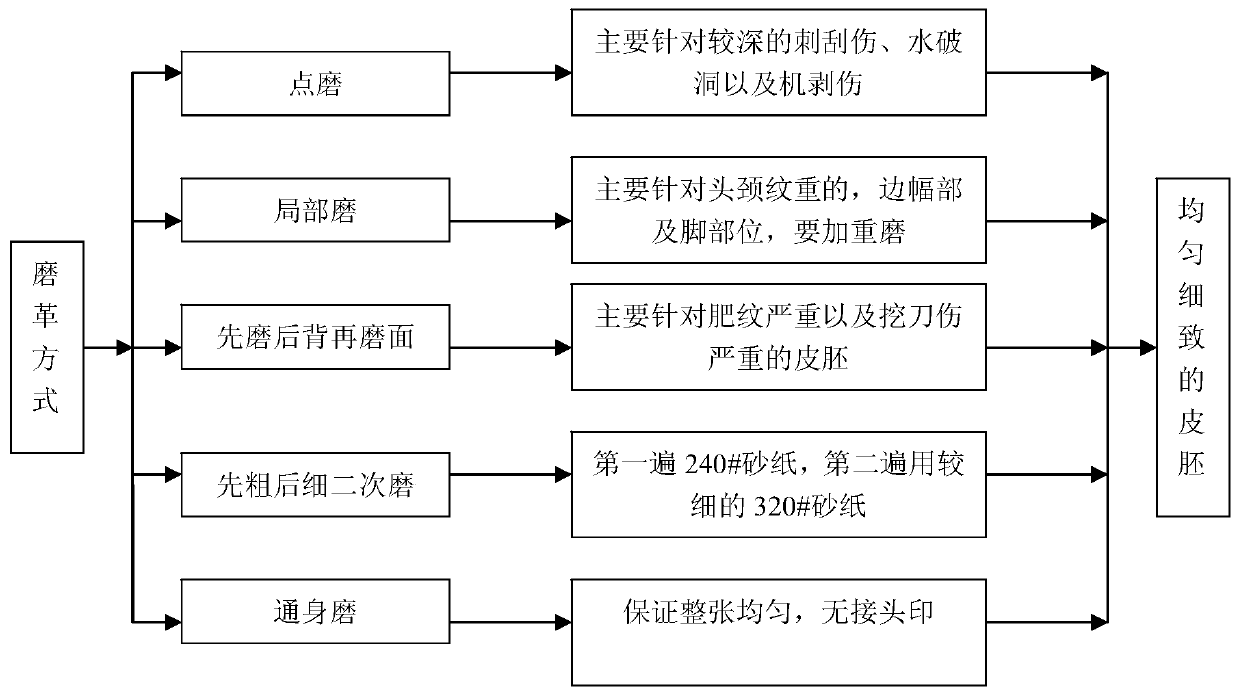

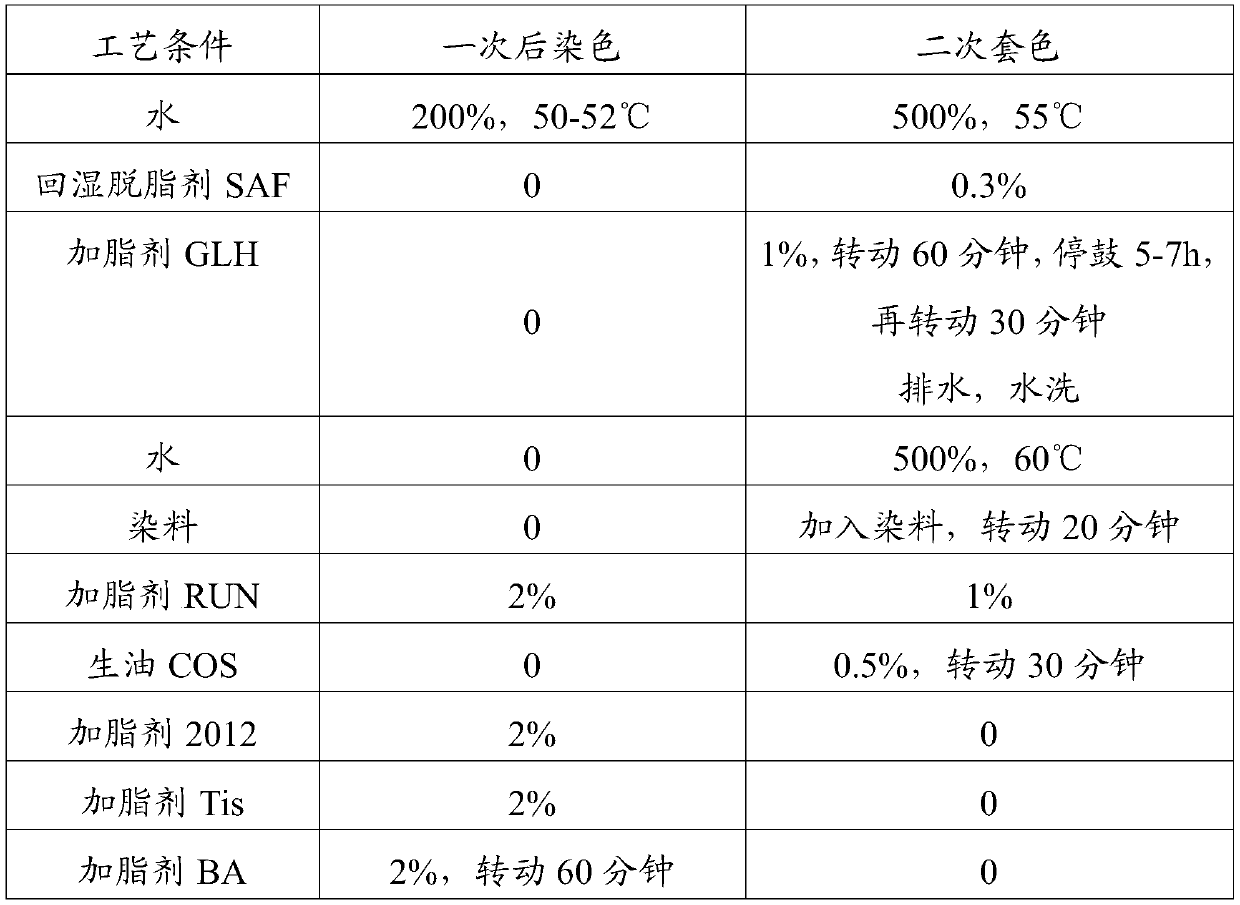

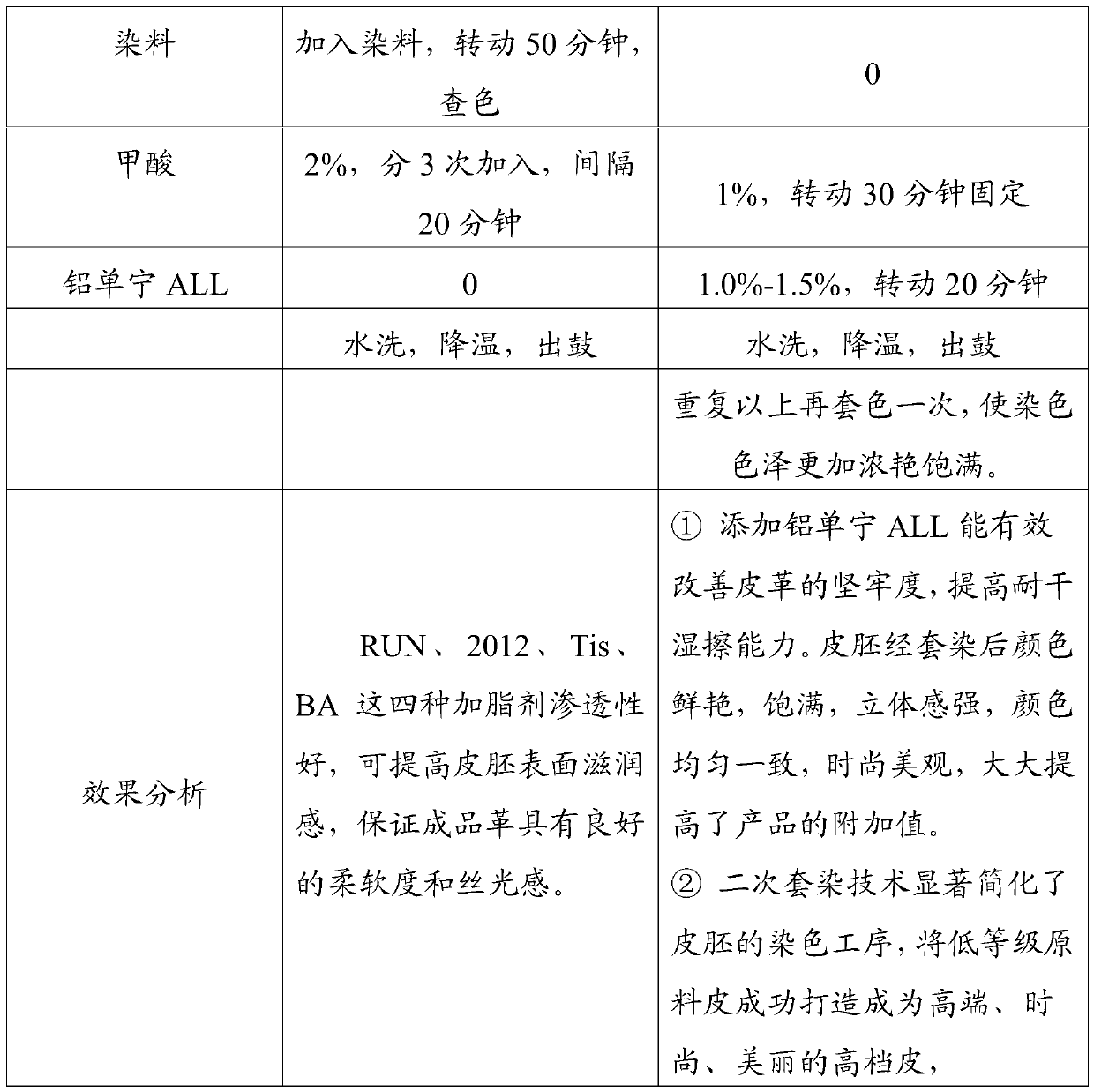

[0022] The invention discloses a method for making high-value secondary over-dyeing nubuck leather, which comprises a material preparation process, a retanning process, a neutralization process, a filling dyeing process, a fatliquoring and re-dyeing process, an acid fixing process, a primary drying process, and a grinding process, which are carried out sequentially. Leather process, secondary coloring process, secondary drying process and surface coating process, etc. Among them, the material preparation process (including the steps of material preparation, water squeezing, shaving and weighing), acid fixation process, primary drying process, secondary drying process and surface coating process are all conventional processes, and conventional operations known in the industry can be adopted. , which will not be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com