Radial horizontal well drilling and sand control completing tool and method

A technology for horizontal drilling and sand control tools, applied in the directions of directional drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems of unstable channel after injection, decrease of permeability around blasthole, and increase of wellbore drainage area, etc. Good sand control and discharge effect, increasing effective wellbore radius and reducing production pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] A method for radial horizontal drilling and sand control well completion The specific implementation steps are as follows:

[0082] 1. Preparation before construction

[0083] 1. Select a drift gauge not smaller than the maximum outer diameter of the pipe string, and pass the well to the bottom of the artificial well.

[0084] 2. After the well is in place, wash the well to replace impurities and crude oil in the well. Pull out the well pipe string and put out the drift gauge, which is required to be intact and free of scratches.

[0085] 2. Construction work

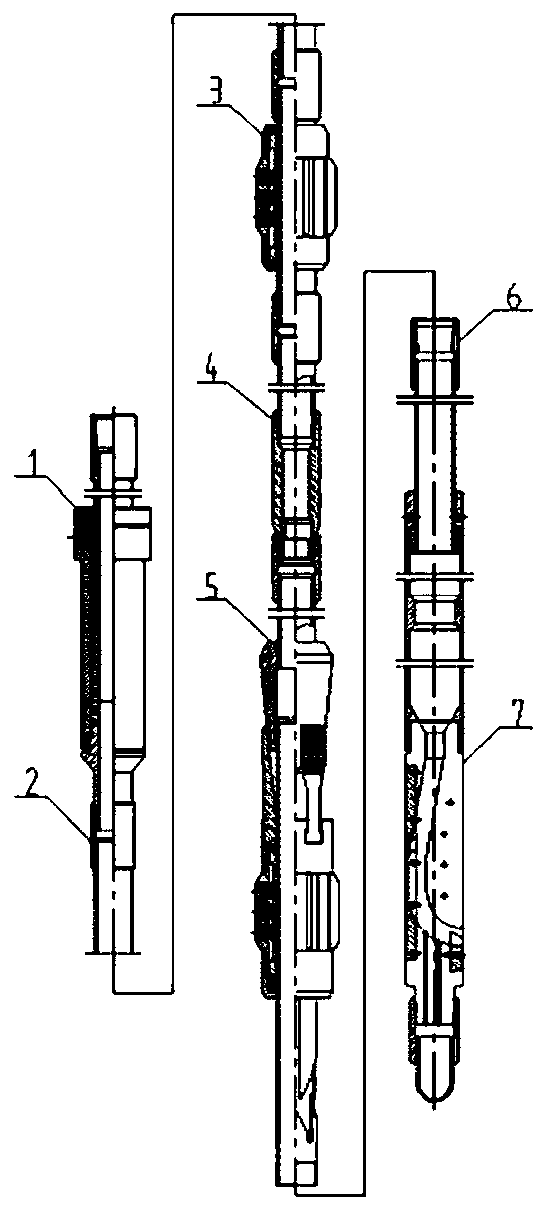

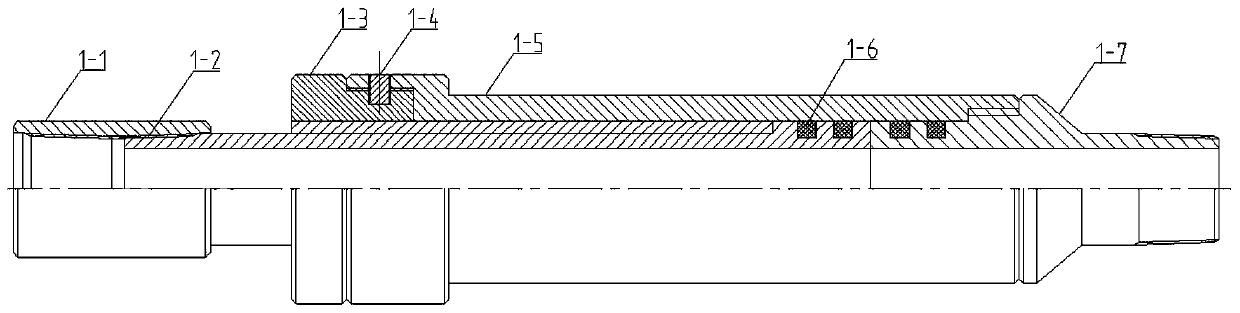

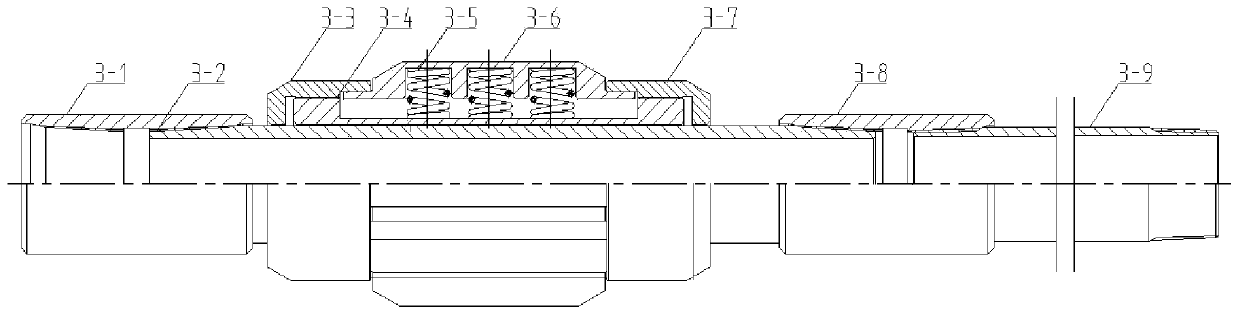

[0086] 1. Lower auxiliary pipe string: debug and measure the drilling guide tool 7, azimuth adjustment tool 6, axial anchor tool 5, azimuth determination auxiliary tool 4, depth calibration tool 3, special tubing assembly 2 and depth adjustment tool 1 , connection, down to the design depth in the well, the depth adjustment tool 1 is installed on the wellhead, which is convenient for rotation adjustment.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com