Device for preparing double-layer composite diaphragm of lithium ion battery and using method thereof

A lithium-ion battery and double-layer composite technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve problems such as not reaching the softening temperature of the binder, deformation of the diaphragm, and inability to adjust the flatness of incoming materials. Achieve the effect of improving production efficiency and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

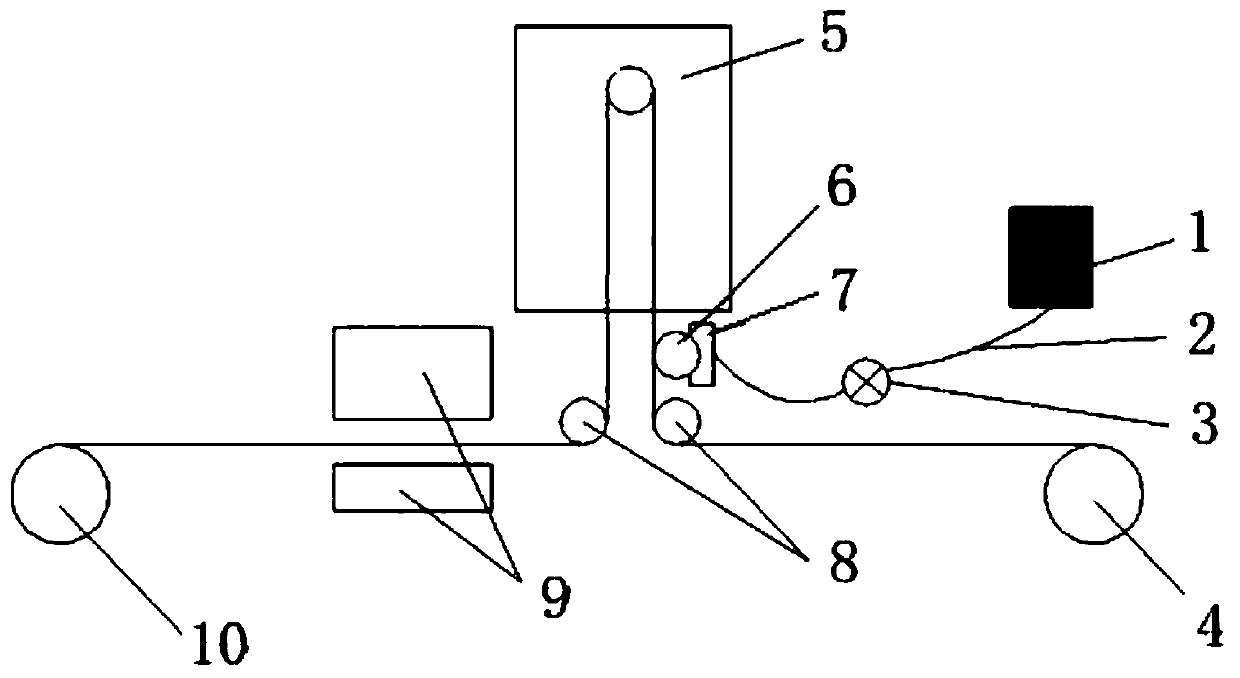

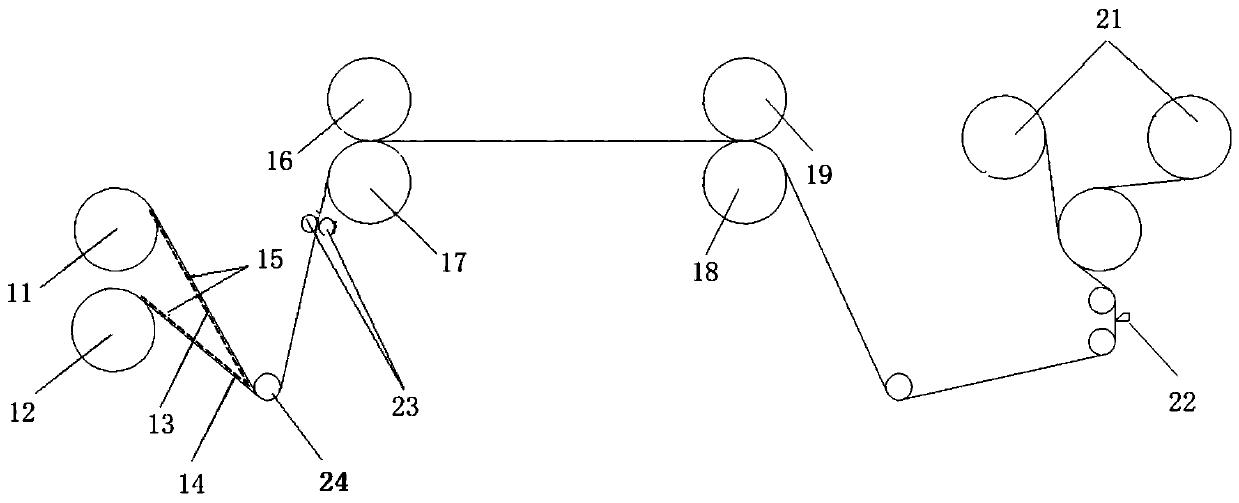

[0040] A device for preparing a double-layer composite diaphragm, including an unwinding mechanism, a hot-pressing mechanism, a cutting mechanism and a winding mechanism, the unwinding mechanism is set at the first station, and the hot-pressing mechanism is set at the second station , the cutting mechanism is set at the third station, and the winding mechanism is set at the fourth station;

[0041]Described unwinding mechanism comprises first unwinding shaft 11 and second unwinding shaft 12, and described first unwinding shaft 11 is arranged on the top of described second unwinding shaft 12, and guide roller 24 is provided with after described unwinding mechanism, uses In order to bring the two kinds of diaphragms closer together, a shearing roller 23 is also arranged between the guide roller 24 and the heat-pressing mechanism, and the shearing roller 23 is composed of two symmetrically arranged upper and lower pairs of rollers 23-2, so The shearing roller 23 forms an angle of...

Embodiment 2

[0047] This embodiment is further optimized on the basis of Embodiment 1.

[0048] As a preferred manner, a thickness detection device is provided between the hot pressing mechanism and the cutting mechanism, for detecting whether the thickness of the compounded diaphragm is uniform.

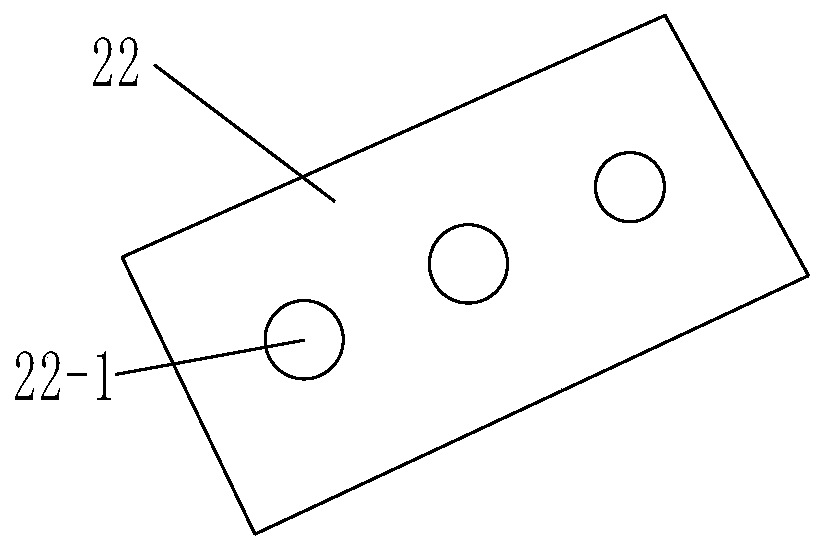

[0049] As a preferred manner, the cutter 22 is made of tungsten steel, which can make the cutting effect better.

[0050] As a preferred manner, the distance between the plurality of cutters 22 is set according to the required width of the double-layer composite membrane.

[0051] As a preferred manner, the cutter 22 has a mounting hole 22-1, which facilitates the installation of the cutter 22, reduces the weight of the cutter 22 itself, and saves materials. The three-hole blade produced by Zhongtai Machinery Blade Co., Ltd. can be selected.

[0052] As a preferred manner, a cooling and shaping roller is arranged in front of the winding shaft 21 to reduce the temperature of the diaphragm so as...

Embodiment 3

[0055] A method for preparing a device for a double-layer composite diaphragm, comprising the steps of:

[0056] 1) On the first diaphragm 13 and the second diaphragm 14, PVDF of 1-2 μm is coated on one side respectively, and the PVDF coating 15 can be sprayed or rolled, and the PVDF slurry is a non-toxic and harmless uniform small particle, and Microscopically, it presents an island-like structure. The island-like structure can play a good buffering effect between the membrane layers, effectively improve the deformation of the diaphragm, provide deformation space for the stress release of the diaphragm, and make the diaphragm more smooth. The coated first diaphragm 13 is placed on the first unwinding shaft 11, the coated second diaphragm 14 is placed on the second unwinding shaft 12, and the first diaphragm 13 on the first unwinding shaft 11 has a PVDF coating. One side of the layer 15 is downward, and the second diaphragm 14 on the second unwinding shaft 12 has a side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com