Concentrated cherry juice beneficial to human health, and production technology thereof

A technology for human health and concentrated juice, which is applied in juice extraction, food science, application, etc., can solve the problems of uneven crushing and slow efficiency, and achieve the effects of improving work efficiency, fast speed, and preventing frying cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 2

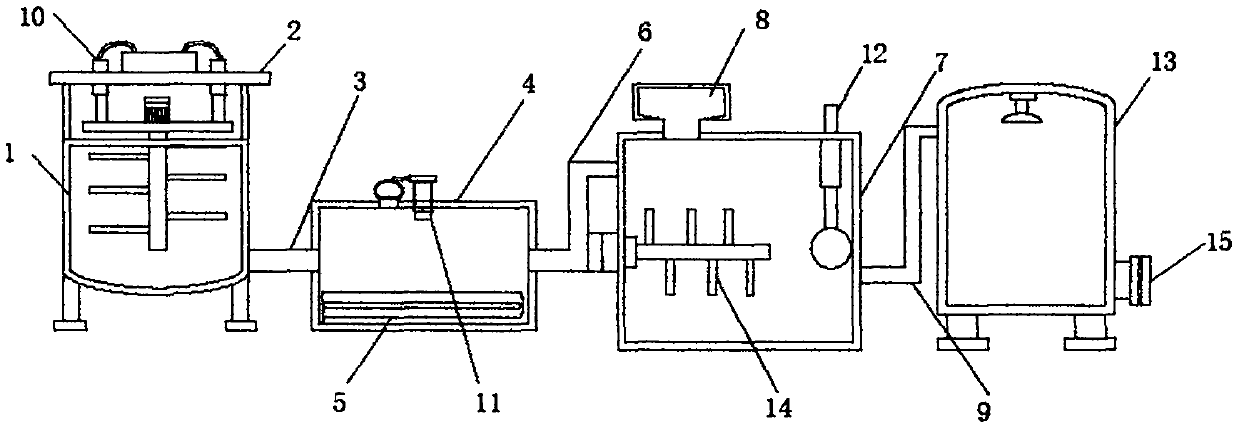

[0047] Implementation Case 2: The production process of concentrated cherry juice that is helpful to human health mainly includes 4 steps: Step 1: Boil the cherries and remove the pits, and then mash and beat them; Step 2: Send the cherry paddles into the heating box 4 , heating to remove moisture, step 3: sending the heated cherry paddle after removing water into the feeding box 7 to add additives, step 4: sending the concentrated cherry juice into the drying tower 13 for drying and granulation.

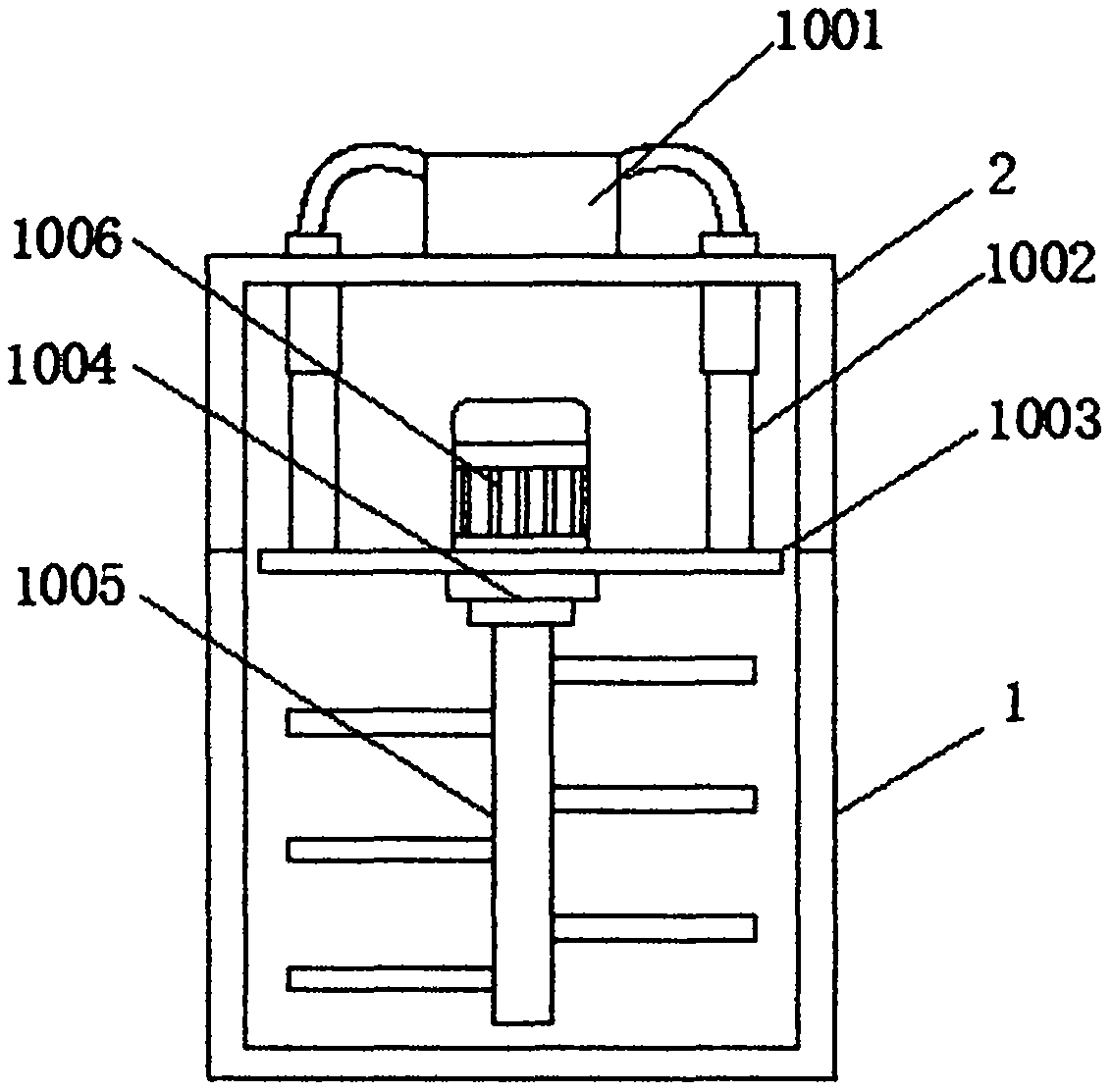

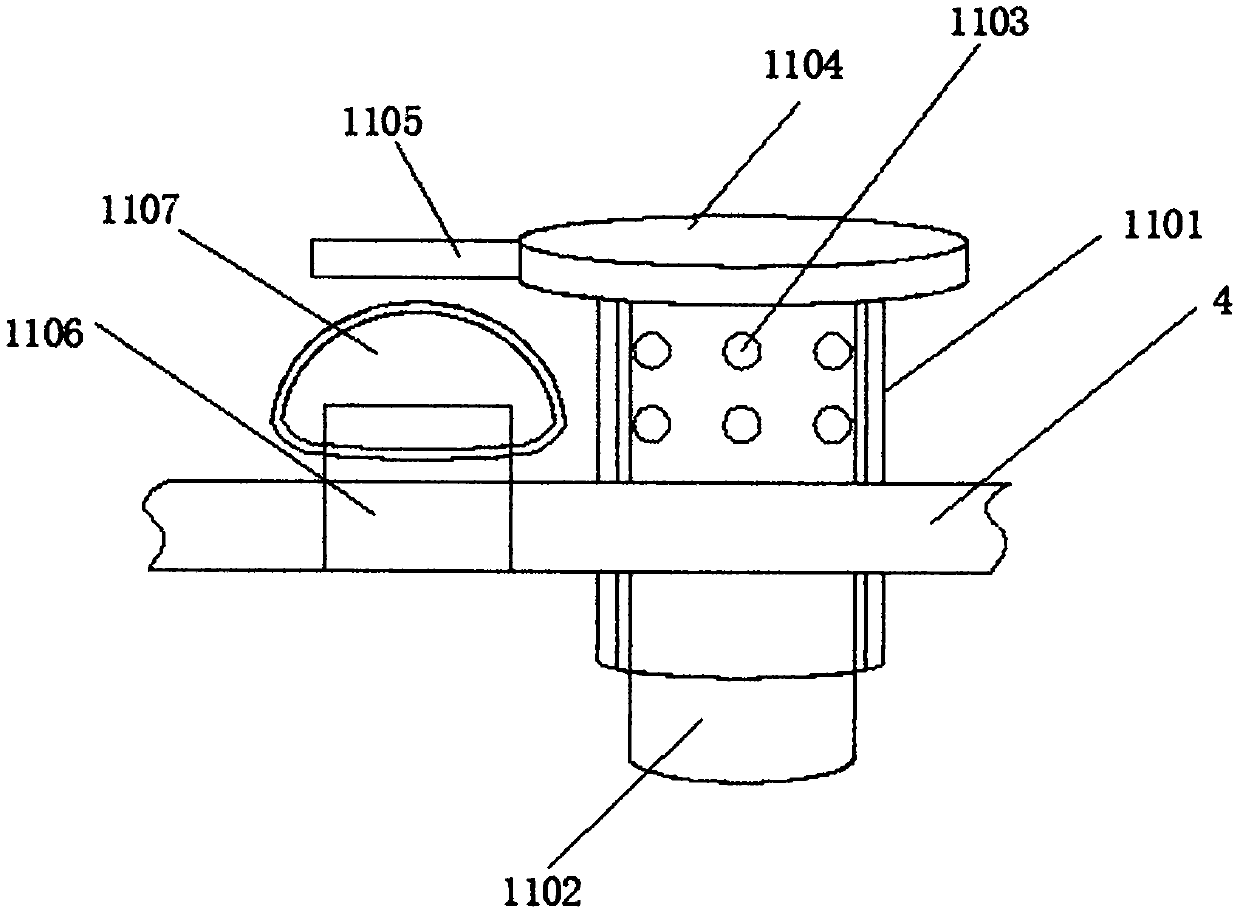

[0048] The detailed content of step 1 is as follows: the cherries are boiled and pitted, and sent into the pulping tank 1, and the stirring knife 1005 is driven by the first motor 1006 to smash and make pulp, and then sent into the pulping tank 1 through the first conveying pipe 3. Inside the heating box 4;

[0049] The details of step 2 are as follows: the fruit pulp is heated through the heating tube 5 at the bottom of the heating box 4 to evaporate the moisture in the fruit pulp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com