Automatic Christmas tree forming and cutting device

A technology of automatic forming and cutting device, applied in special decorative structures, decorative arts, fabrics for floors, etc., can solve the problems of low pruning efficiency, low environmental damage, large labor load, etc., to improve product competitiveness and save money. Feeding time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

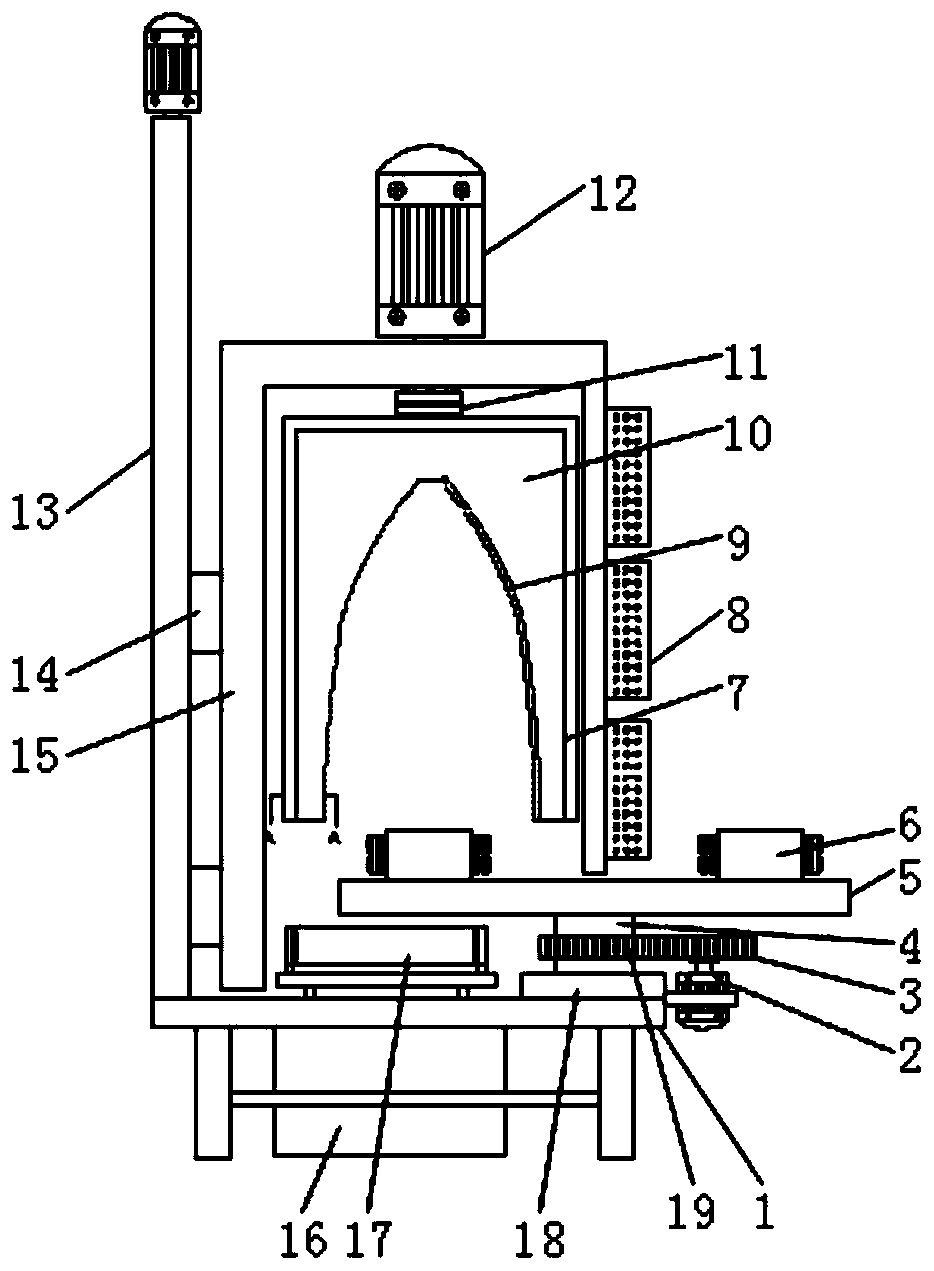

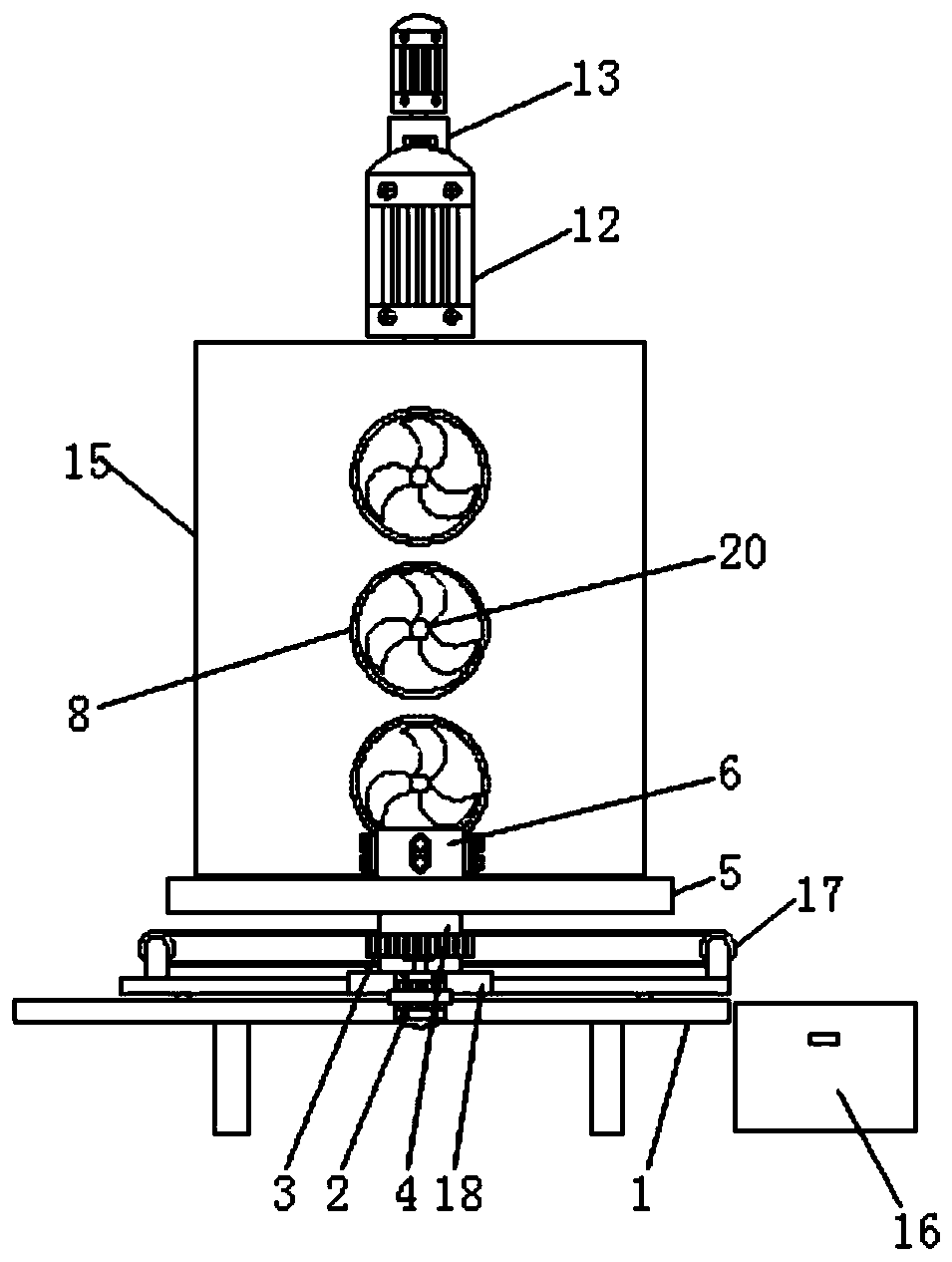

[0031] Embodiment one, with reference to Figure 1-2 with Figure 5-6 , a Christmas tree automatic molding and cutting device, including an installation platform 1 and a lead screw 13, a lead screw 13 is vertically installed at one end of the top surface of the installation platform 1, and a moving block 14 is slidably connected to the surface of the lead screw 13, which is a common structure, here Without going into too much detail, an outer cover 15 is fixedly installed on the other side surface of the moving block 14, and a rotating base 18 is installed on the other end of the top surface of the installation platform 1, and the rotating base 18 is internally connected with a rotating column 4, wherein the rotating column 4 The bottom surface is welded with a disc 25, and the disc 25 is located inside the rotating base 18, and a ball 26 is rollingly connected between the top surface and the bottom surface of the disc 25 and the inner top surface and the inner bottom surface ...

Embodiment 2

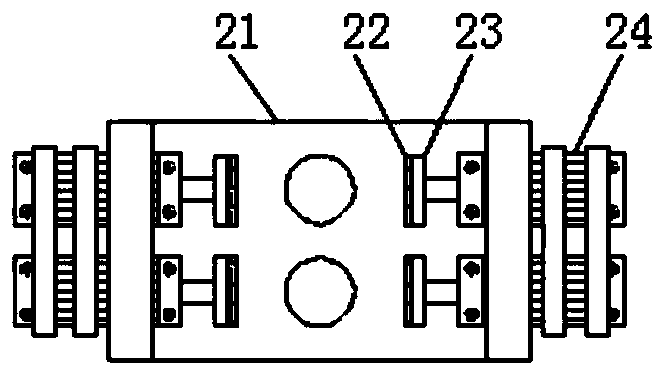

[0032] Embodiment two, refer to Figure 1-4, the clamping seat 6 is composed of a fixed ring 21, a cylinder 24, an extruded plate 23 and a friction pad 22, and the surface of the fixed ring 21 is fixedly connected with a cylinder 24, and the other end of the cylinder 24 is fixedly connected with an extruded plate 23, wherein, A friction pad 22 is pasted on the surface of the other side of the extruding plate 23, and the friction pad 22 is made of rubber material, and the surface of the friction pad 22 is a rough structure, which improves the friction force when the extrusion is fixed. There are two layers up and down, and the upper and lower cylinders 24 are fixedly connected, and the pine trunk is fixed up and down on multiple sides to prevent the pine tree from toppling over, and the fixation is more stable. The inside of the clamping seat 6 is clamped by the cylinder 24. Bottom surface is placed in fixed ring 21, elongation cylinder 24, and cylinder 24 elongation promotes e...

Embodiment 3

[0033] Embodiment three, refer to Figure 1-2 , the surface of one side of the outer cover 15 is connected with a fan box 8, and the inside of the fan box 8 is fixedly installed with an axial flow fan 20. The bottom of the rotating disk 5 is located directly below the cutting edge 9, and the top surface of the installation platform 1 is provided with a conveyor belt 17, and the conveyor belt 17 One end is positioned at installation platform 1 side and is placed with waste basket 16, and when pruning and cutting, outer cover 15 prevents the branches and leaves of pruning from splashing, and axial flow fan 20 blows out the airflow and blows off the branches and leaves of pruning and hanging on the pine tree, making the finished product more Clean, the leaves and branches that are blown off and cut off fall on the conveyor belt 17, and are sent into the waste basket 16 for recycling, avoiding pollution of the surrounding environment, making the processing site clean and tidy, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com