Polishing-force-controlled flexible polishing tool

A technology of flexible polishing and polishing force, which is applied in the direction of manufacturing tools, grinding/polishing equipment, and workpiece feed movement control, etc. It can solve the problems of high surface quality and surface shape accuracy, easy edge effects, and low precision. Achieve high-precision processing, avoid intermediate frequency errors, and reduce edge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment, but should not limit protection scope of the present invention with this.

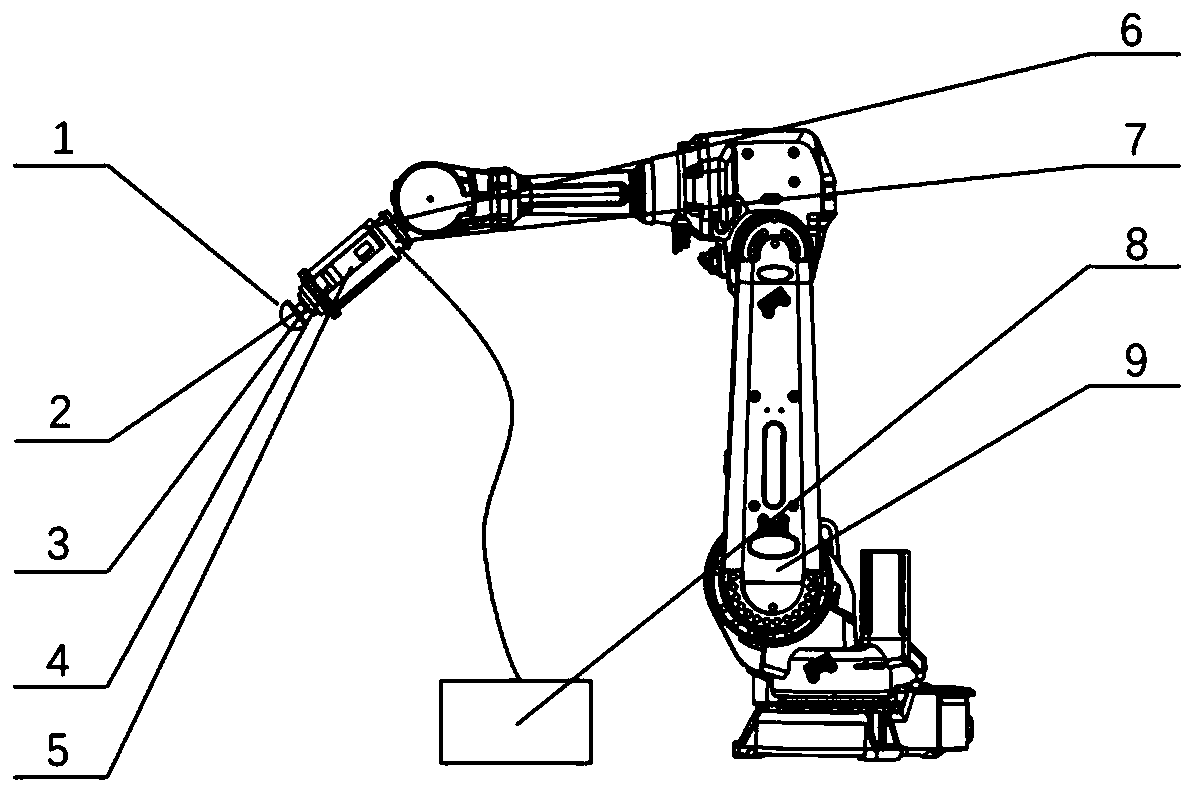

[0031] refer to figure 2 , figure 2 It is a schematic diagram of a polishing force control flexible polishing tool working with a robot. It can be seen from the figure that a polishing force control flexible polishing tool of the present invention is used in an embodiment of a meter-level large-diameter optical element fast and efficient polishing machine. The polishing force control flexible polishing tool includes Flexible tool 1, chuck seat 2, connecting plate 3, reducer 4, servo motor 5, frame 6, force sensor 7 and force control system 8. Cooperate with the industrial robot 9 to complete the processing work.

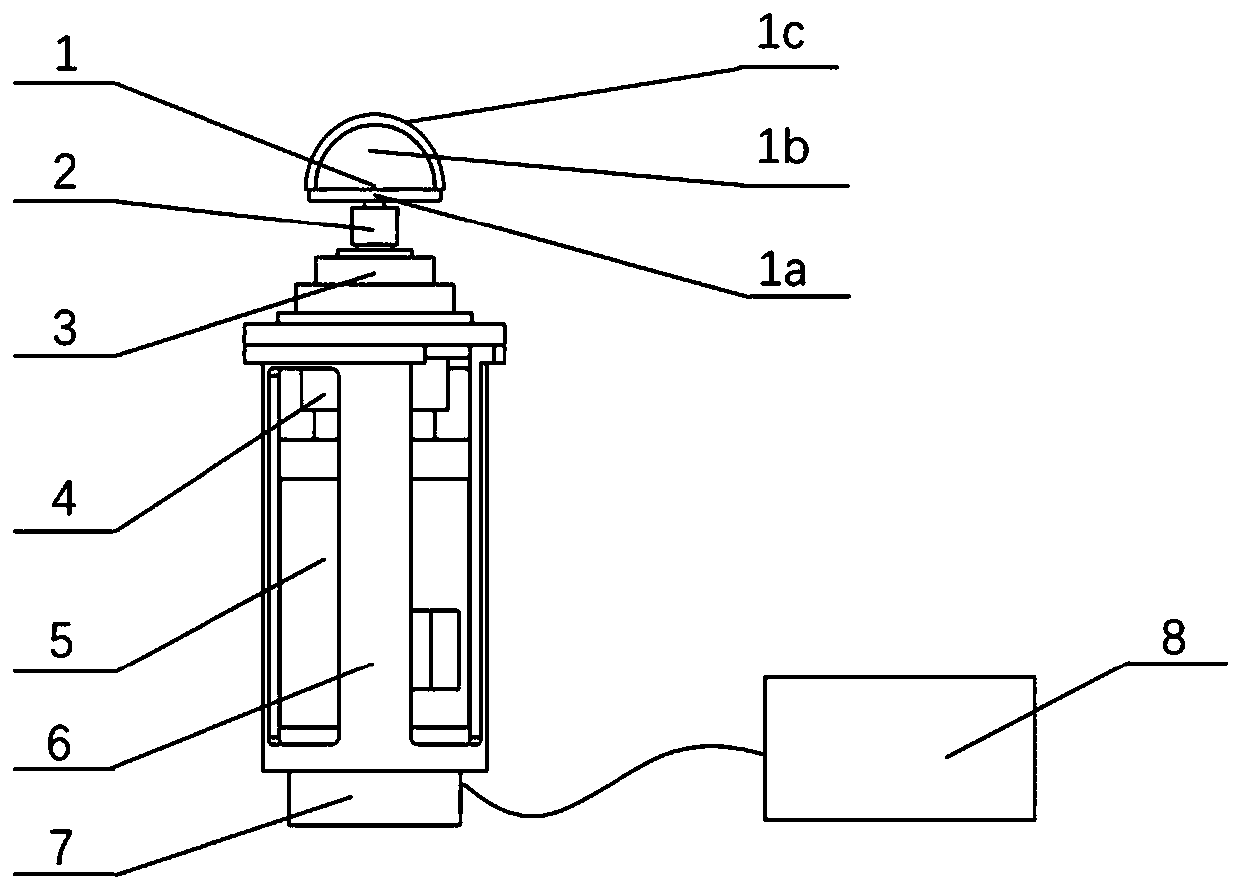

[0032] The flexible tool is composed of a clamp 1a, an elastic layer 1b and a polishing leather 1c. The fixture is used to connect the collet seat 2 and the elastic layer 1b; the elastic layer 1b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com