630 DEG C secondary reheating unit thermodynamic system

A thermal system, secondary reheating technology, applied in the directions of preheating, supporting machines, mechanical equipment, etc., can solve the problems of increased thermal capacity, increased thermal inertia, etc., to improve thermal effect, avoid excessive increase, and improve handling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

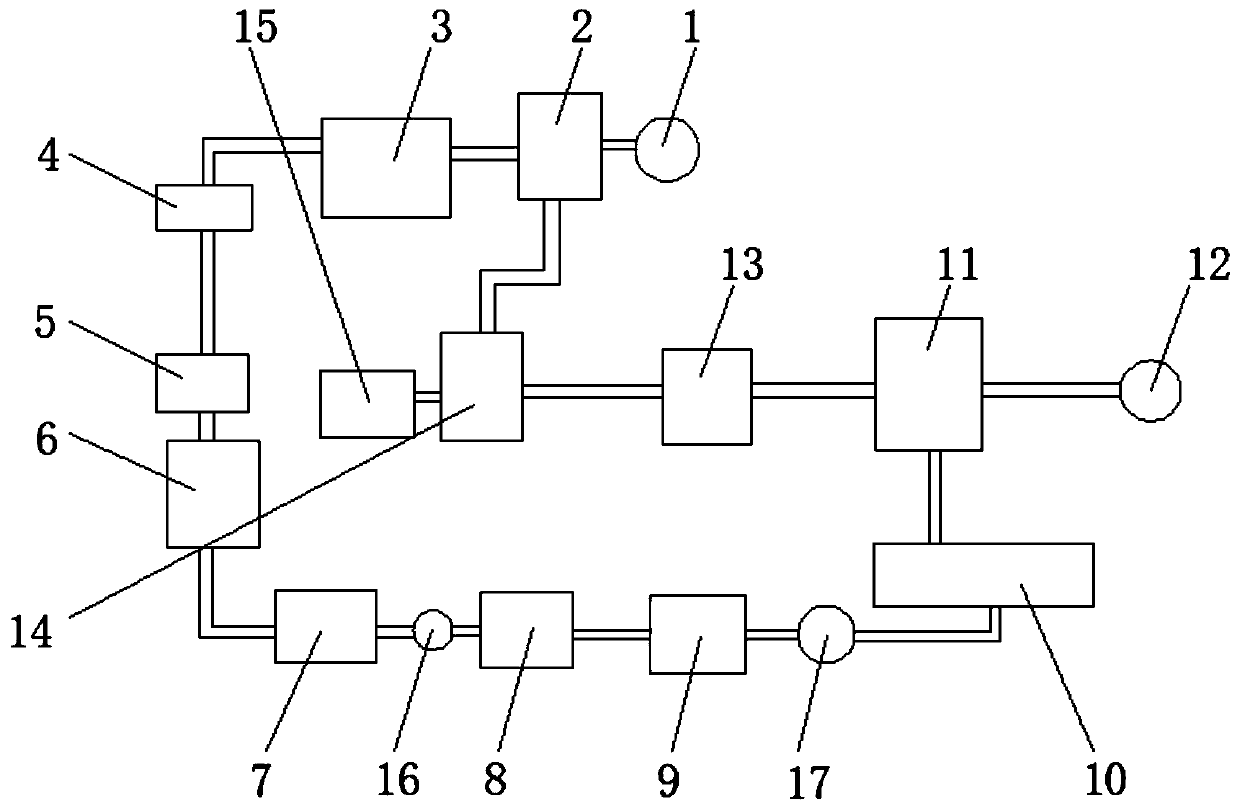

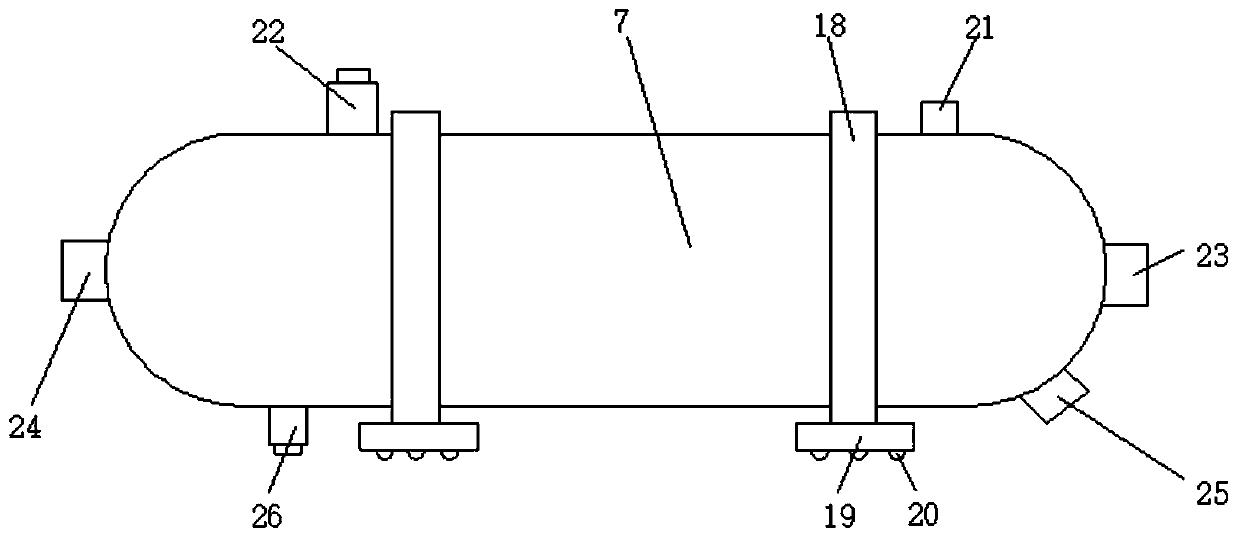

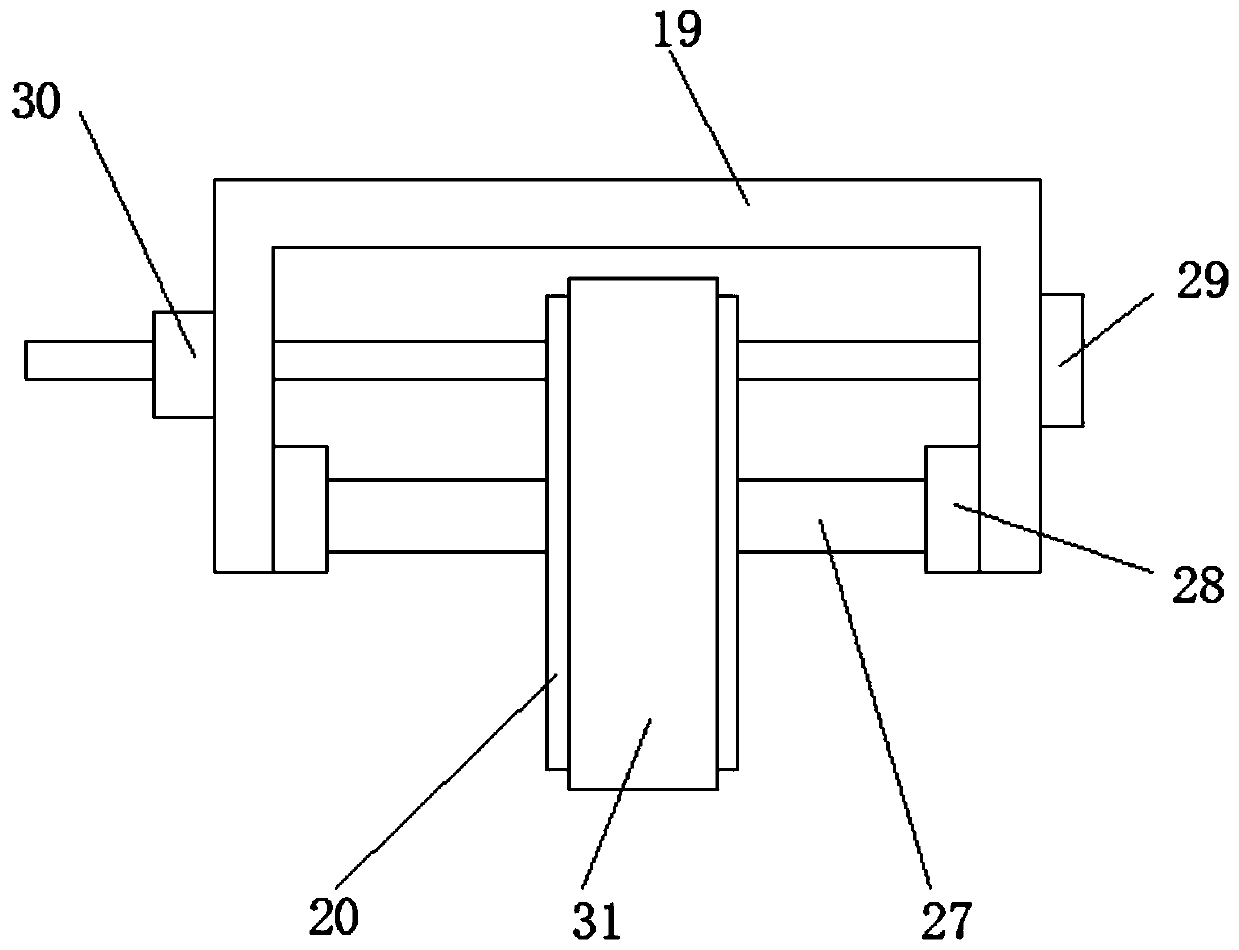

[0027] refer to Figure 1-2 , a thermal system of a 630°C double reheat unit, comprising a first generator 1, one end of the first generator 1 is fixedly connected to an ultra-high pressure cylinder 2, and one end of the ultra-high pressure cylinder 2 away from the first generator 1 is fixedly connected to a The first reheater 3, the end of the first reheater 3 away from the ultra-high pressure cylinder 2 is fixedly connected with a superheater 4, the lower end of the superheater 4 is fixedly connected with an economizer 5, and the lower end of the economizer 5 is fixedly connected with a second A high-pressure heater 6, the lower end of the first high-pressure heater 6 is fixedly connected with a second high-pressure heater 7, and the end of the second high-pressure heater 7 away from the first high-pressure heater 6 is fixedly connected with a deaerator 8, and the deaerator 8 A low-pressure heater 9 is fixedly connected to one end away from the second high-pressure heater 7,...

Embodiment 2

[0035] refer to Figure 1-4 , a thermal system of a 630°C double reheat unit, comprising a first generator 1, one end of the first generator 1 is fixedly connected to an ultra-high pressure cylinder 2, and one end of the ultra-high pressure cylinder 2 away from the first generator 1 is fixedly connected to a The first reheater 3, the end of the first reheater 3 away from the ultra-high pressure cylinder 2 is fixedly connected with a superheater 4, the lower end of the superheater 4 is fixedly connected with an economizer 5, and the lower end of the economizer 5 is fixedly connected with a second A high-pressure heater 6, the lower end of the first high-pressure heater 6 is fixedly connected with a second high-pressure heater 7, and the end of the second high-pressure heater 7 away from the first high-pressure heater 6 is fixedly connected with a deaerator 8, and the deaerator 8 A low-pressure heater 9 is fixedly connected to one end away from the second high-pressure heater 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com