Method for manufacturing rare earth permanent magnet ring by adopting hot pressing-thermal deformation process and special die

A rare-earth permanent magnet and hot-pressing mold technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, and magnetic materials, can solve problems such as internal stress, magnetic ring cracking, and uneven stress distribution. The effect of improving process tact, improving thermal deformation ability, improving formability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

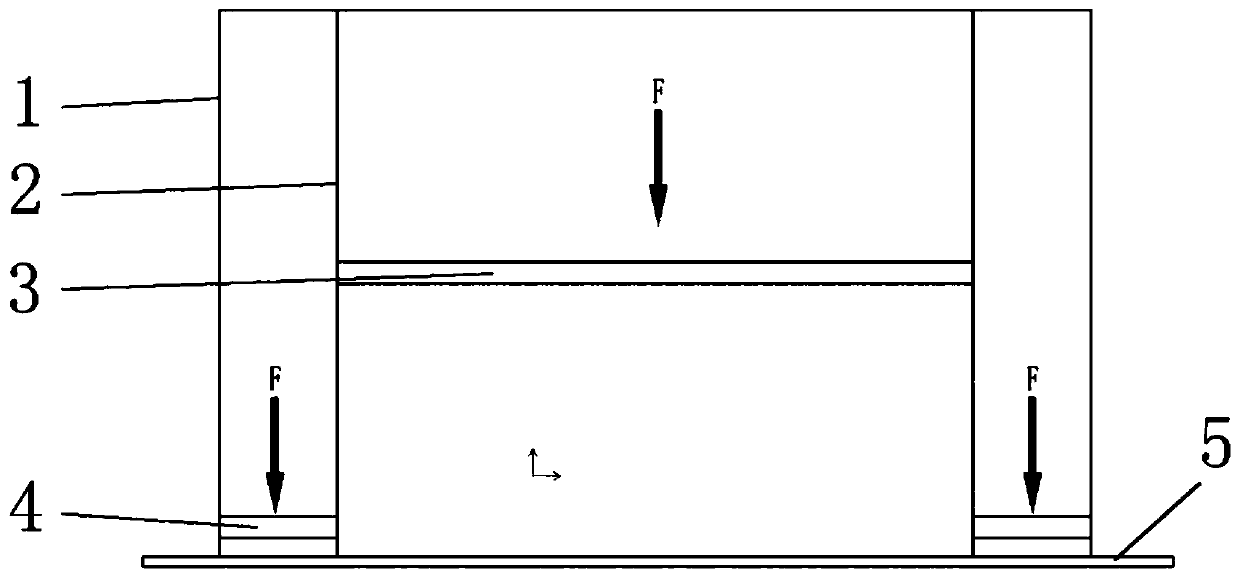

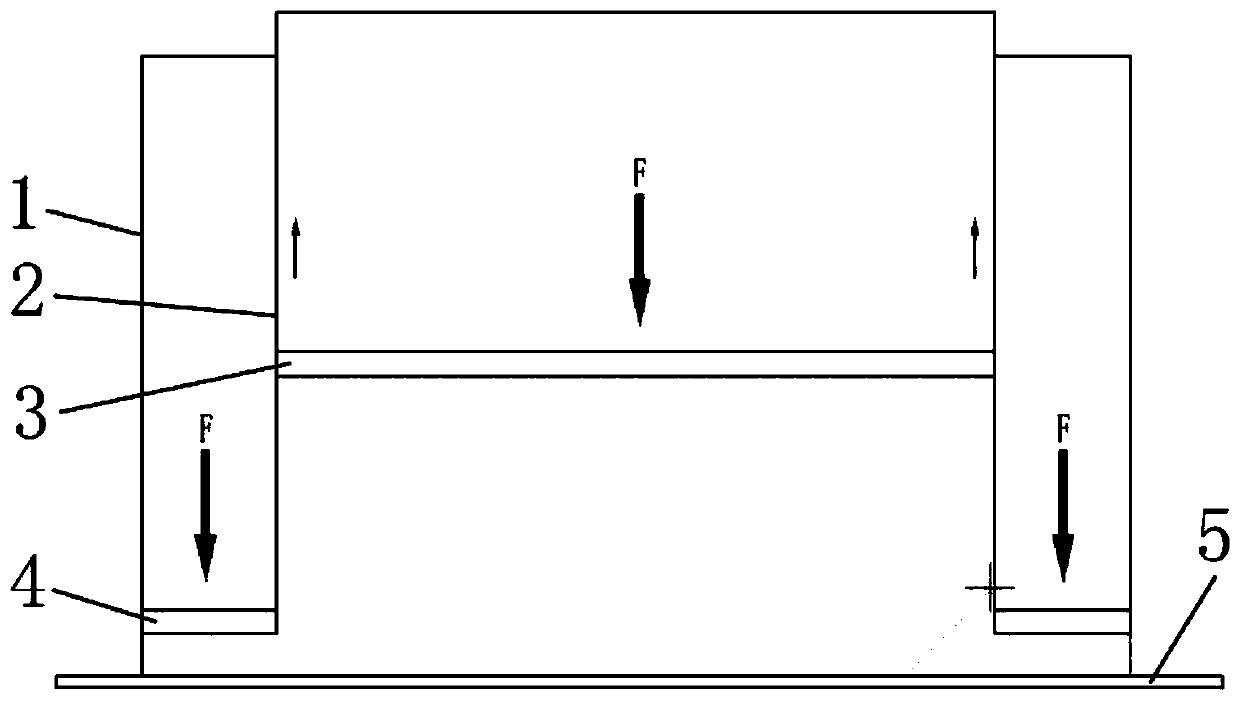

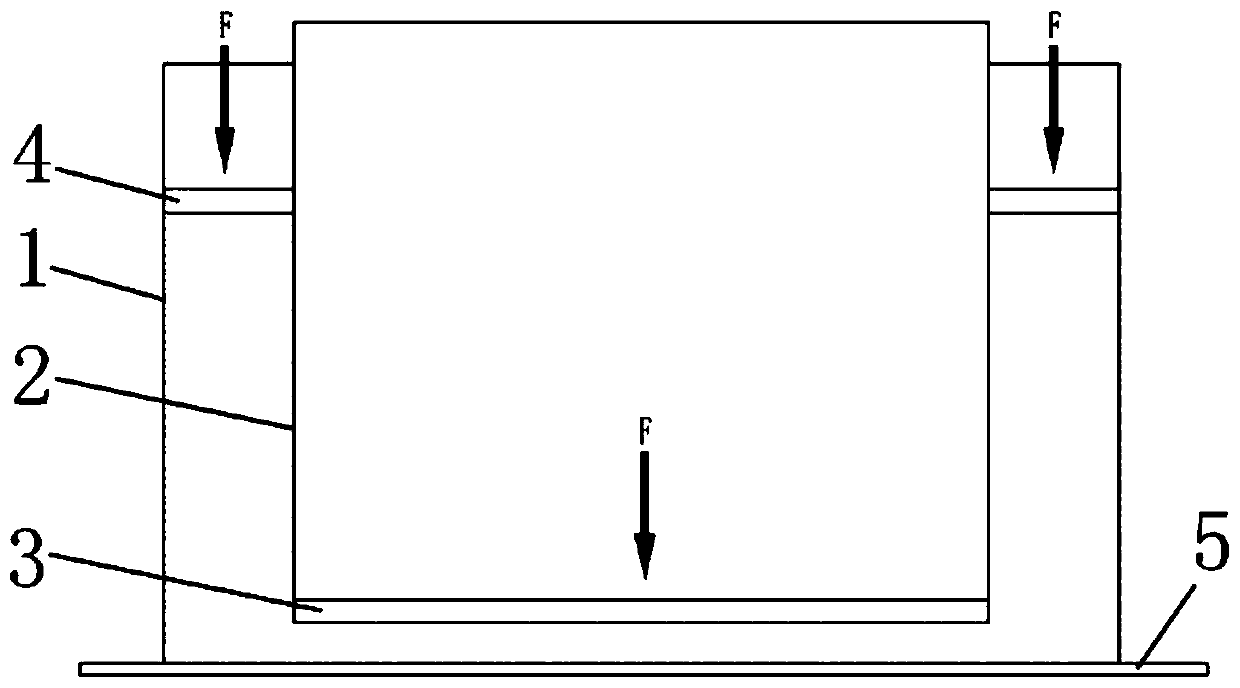

[0045] Select quick quenching permanent magnet powder Nd 2 Fe 14 B, crush the magnetic powder to no more than 120 meshes, add a lubricant to the magnetic powder and mix it evenly, and put it into the hot pressing-thermal deformation mold of the vacuum induction hot press (such as Figure 1-Figure 4 As shown), the hot pressing temperature is set to 780°C, the heating rate is 3°C / s, and the argon protective gas is injected after vacuuming. In the hot pressing step, the intermittent pressing mode is established, and the pressing amount is the preset block 1 / 4 of the body height, stop pressing down, keep the pressure for 8 seconds, and then continue to press down, so that the pressure is kept intermittently for 3 times, and pressed into a dense permanent magnet block with a diameter of 12mm and a height of 14mm.

[0046] Then, heat deformation treatment is carried out by means of back extrusion, the inner mold 2 is moved up, leaving a 0.3cm gap with the bottom plate 5, the heat de...

Embodiment 2

[0049] Select quick quenching permanent magnet powder Nd 2 Fe 14 B, crush the magnetic powder to no more than 120 meshes, add a lubricant to the magnetic powder and mix it evenly, and put it into the hot pressing-thermal deformation mold of the vacuum induction hot press (such as Figure 1-Figure 4 As shown), the hot pressing temperature is set to 820°C, the heating rate is 3°C / s, and the argon protective gas is injected after vacuuming. In the hot pressing step, the intermittent pressing mode is established, and the pressing amount is the preset block When the body height is 1 / 5, stop pressing down, keep the pressure for 6 seconds, and then continue to press down, so that the pressure is kept intermittently for 4 times, and pressed into a dense permanent magnet block, the specifications are: diameter 16mm, height 19mm.

[0050] Then, carry out thermal deformation treatment by means of back extrusion, move the inner mold 2 upwards, leave a 0.3cm gap with the bottom plate 5, se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com