Method for treating acid mine wastewater based on engineering barrier multistage time sequence resistance control

An acid mine wastewater and barrier technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problems of limited treatment effect, low maintenance cost, large floor space, etc., and achieve large-scale applications Value, easy on-site construction, good repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

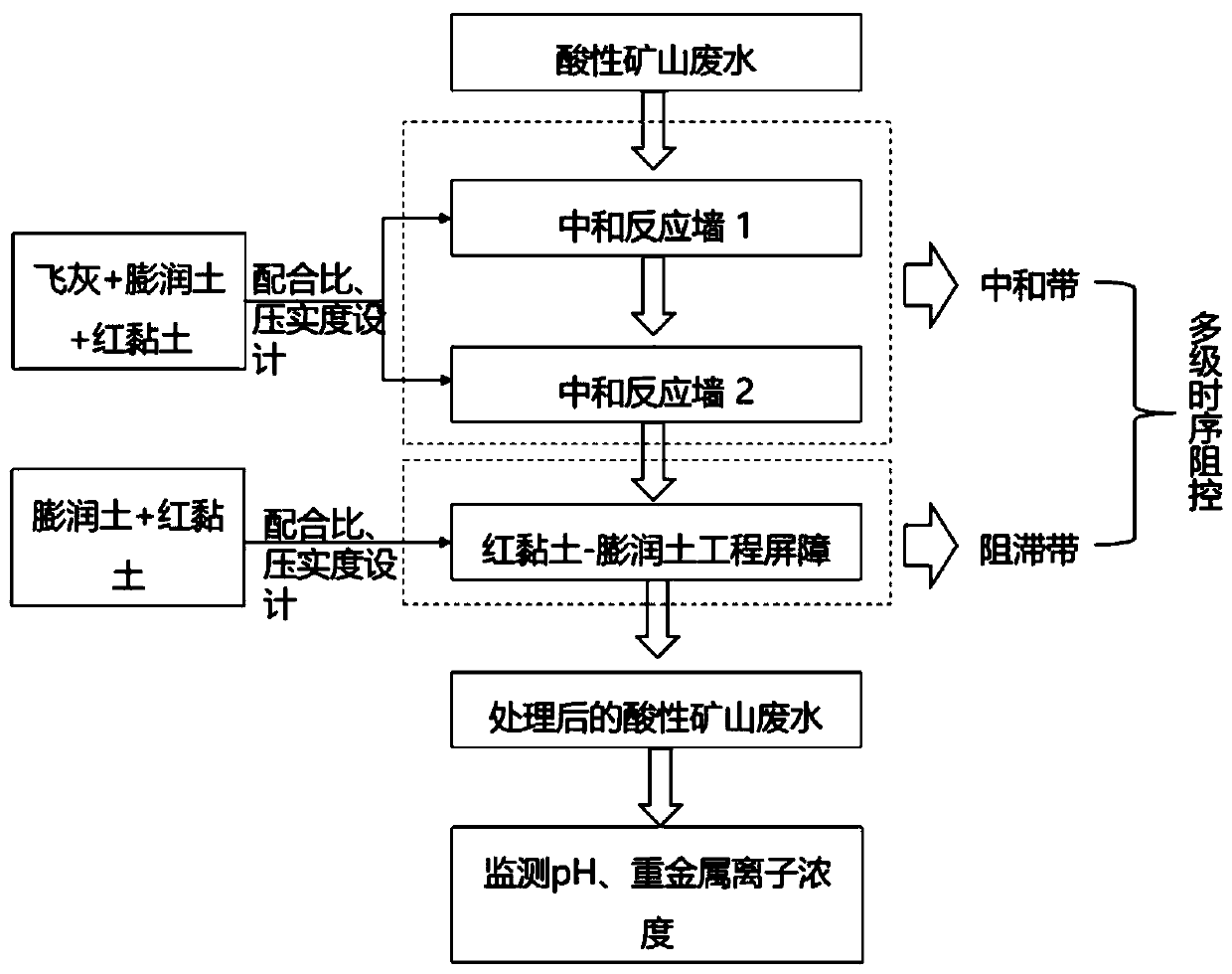

[0044] A method for treating acidic mine wastewater based on engineering barrier multi-level time-sequential resistance control, the adopted process is as follows figure 1 As shown, the specific steps are as follows:

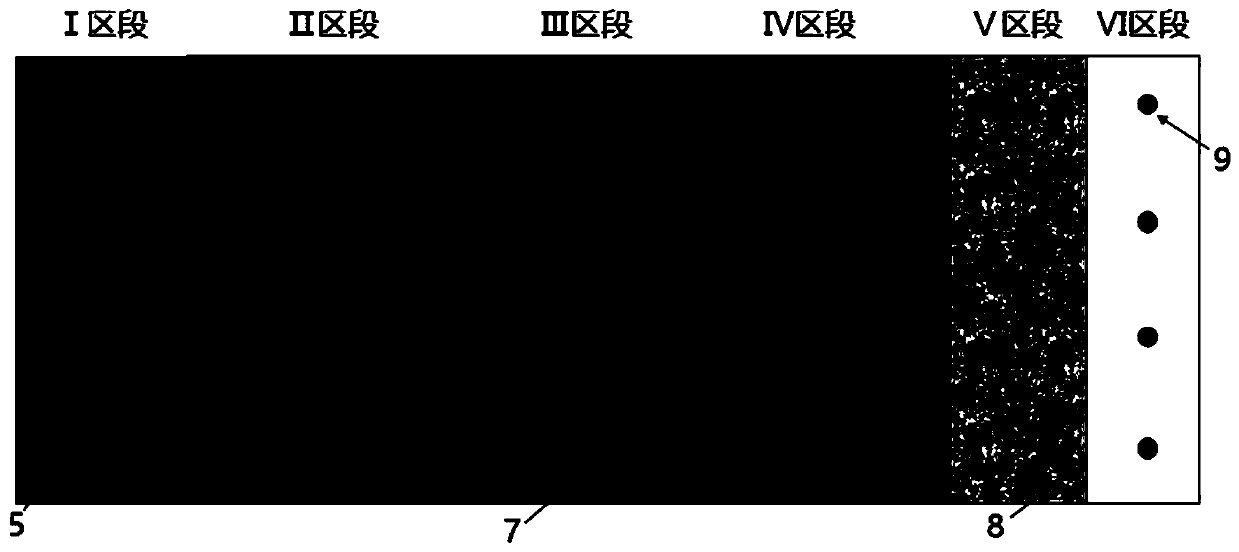

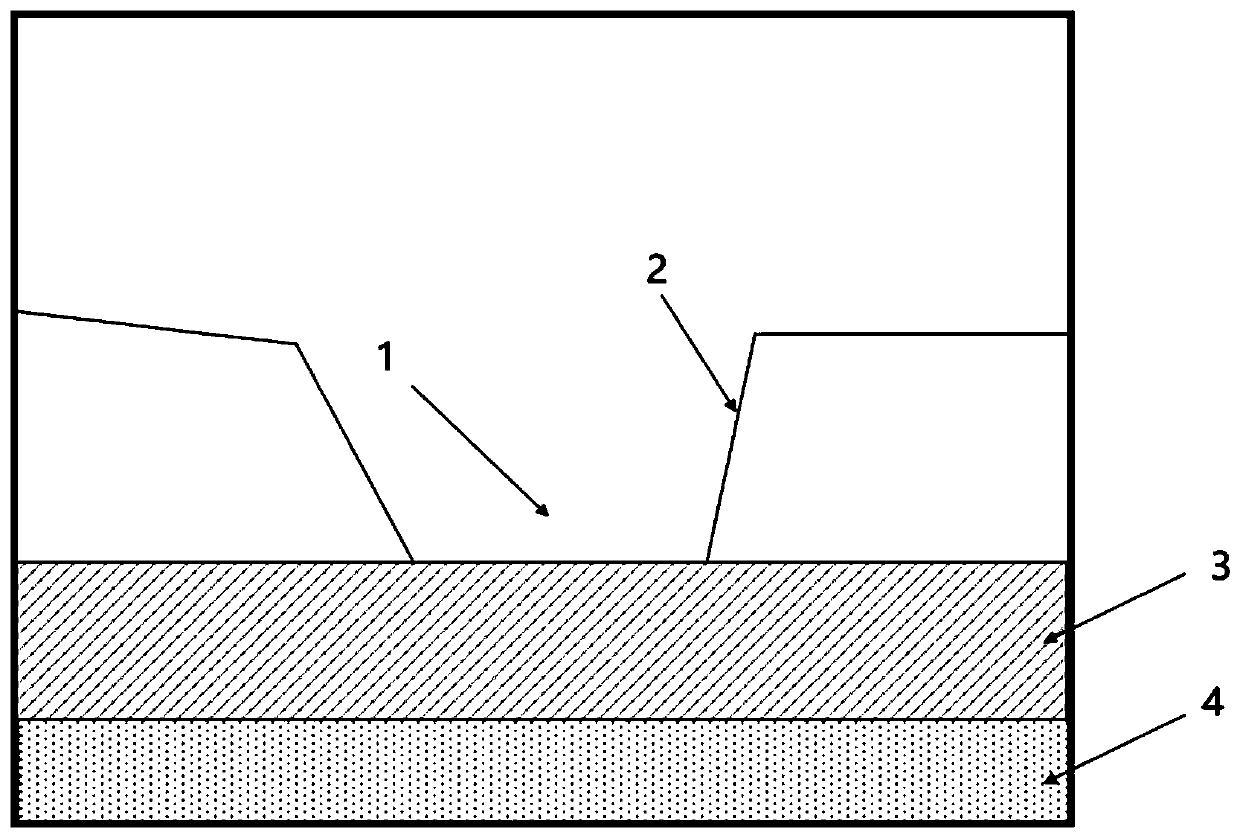

[0045] (1) First, the acid mine wastewater treatment site is divided into 6 sections along the direction of wastewater flow, see figure 2 , including:

[0046] Section I is the first neutralization reaction section for laying out the neutralization reaction wall 1;

[0047] Section II is the original stratum section;

[0048] Section III is used to arrange the second neutralization reaction section of the neutralization reaction wall 2;

[0049] Section IV is the original formation section, and three monitoring points are set in this section;

[0050] Section V is used to lay out the metal ion adsorption section of the red clay-bentonite soil engineering barrier;

[0051] Section VI is the final monitoring section, with 4 monitoring points.

[0052] (2) U...

Embodiment 2

[0071] Investigate the influence of different components and different contents of backfill soil in the engineering barrier wall on the treatment of acid mine wastewater: set up three experimental groups:

[0072] Experimental group 1: the backfill soil A in the tank a of section I is composed of red clay, fly ash and bentonite, and the corresponding mass ratio is 30:60:10; the backfill soil B in the tank b of section III is composed of red clay It is composed of clay, fly ash and bentonite, and its corresponding mass ratio is 60:25:15; the backfill soil C in the tank c of section V is composed of red clay and bentonite, and its mass ratio is 90:10.

[0073] Experimental group 2: The backfill soil A in the tank body a of section I is composed of red clay, fly ash and bentonite, and the corresponding mass ratio is 30:55:15; the backfill soil B in the tank body b of section III is composed of red clay It is composed of clay, fly ash and bentonite, and its corresponding mass rati...

Embodiment 3

[0088] Referring to the method of embodiment 1, the difference is: (5) the backfill soil prepared in step 4 is compacted into a block, and the pieces are put into corresponding reinforcement cages and tank bodies, and the compaction degree of the backfill soil A in the reinforcement cage is respectively The setting is 80%, 90%, 94%; the compaction degree of backfill soil B is 94%; the compaction degree of backfill soil C in tank c is 98%.

[0089] Figure 5 It is the final monitoring data of pH in section VI of backfill A under different compaction degrees.

[0090] from Figure 5 It can be seen from the figure that when the compaction degree of backfill soil A is 80%, the pores of the mixed soil are large, the residence time of acid wastewater in the first neutralization reaction stage is short, the acid mine wastewater is not completely neutralized, and the final monitoring value of pH is less than 7 (4.62). When the compaction degree of the backfill is 94%, the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com