Method and system for continuous kettle type industrial production of crude acetal product

A production method and technology of continuous kettle, applied in the field of continuous kettle industrial production method and system of crude acetal, can solve the problems of material and energy loss, unsuitability for large-scale industrial production, prolonging production cycle, etc., to achieve acetal The content is increased, which is beneficial to large-scale industrial production and the effect of inhibiting side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

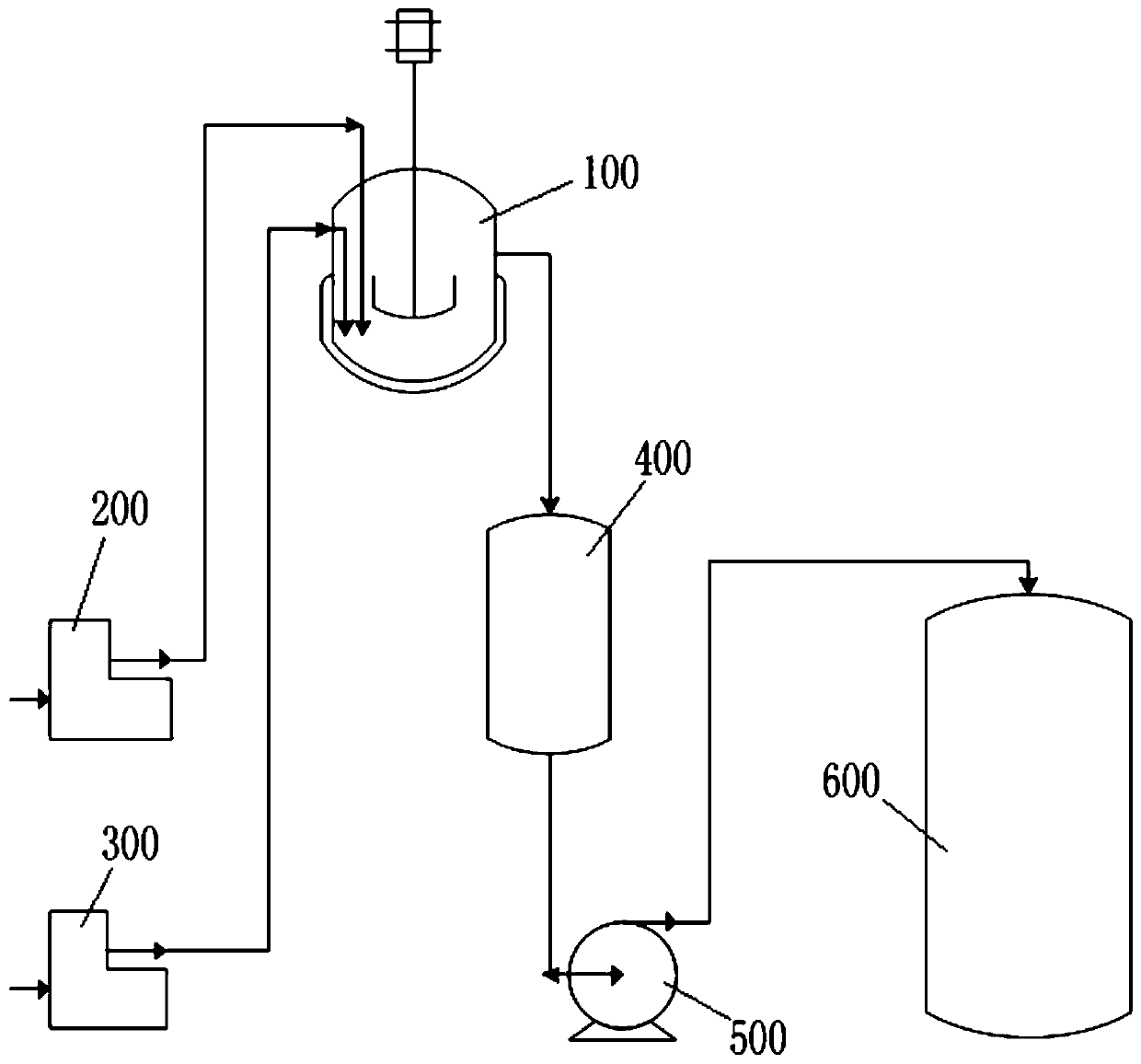

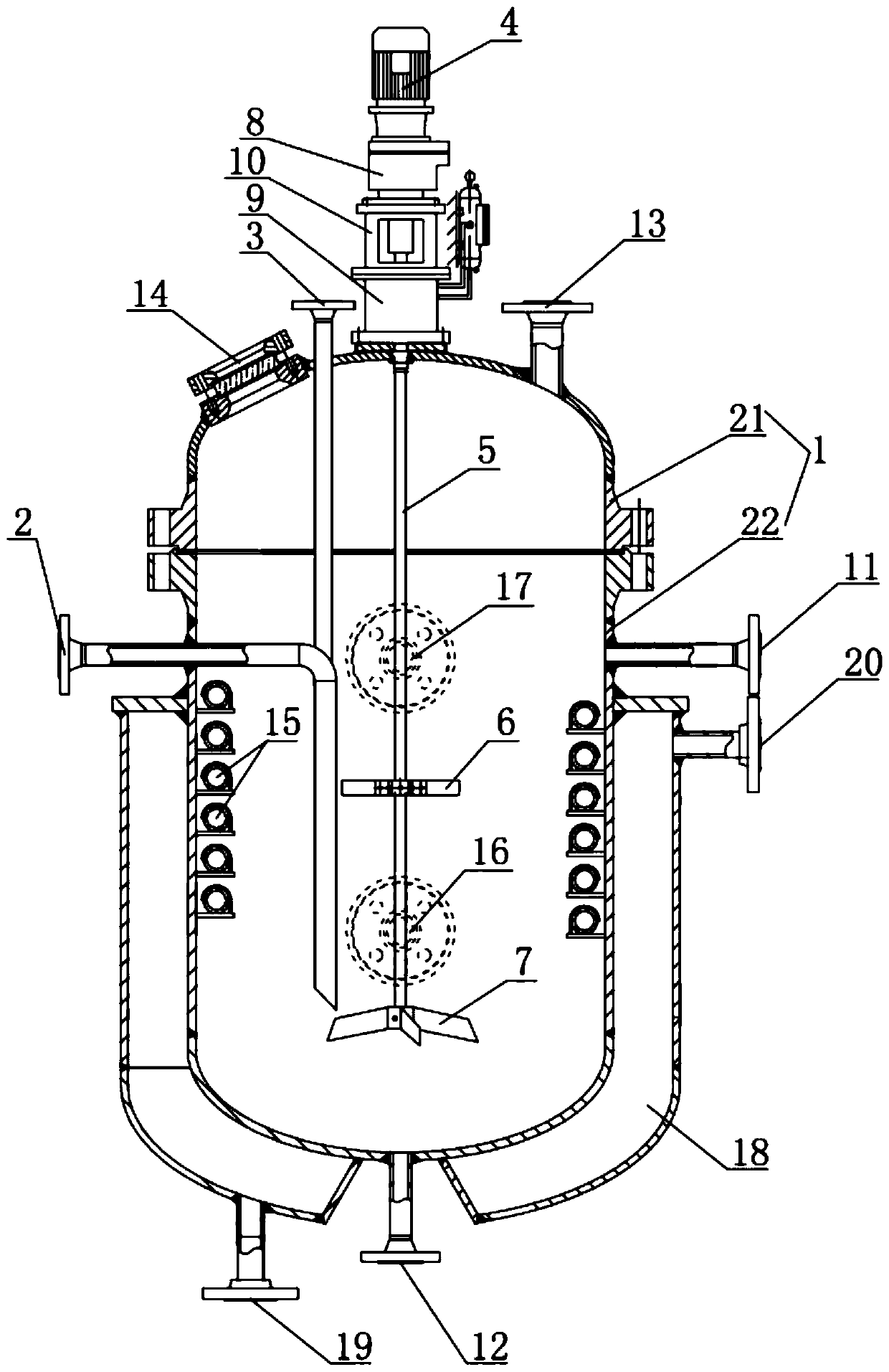

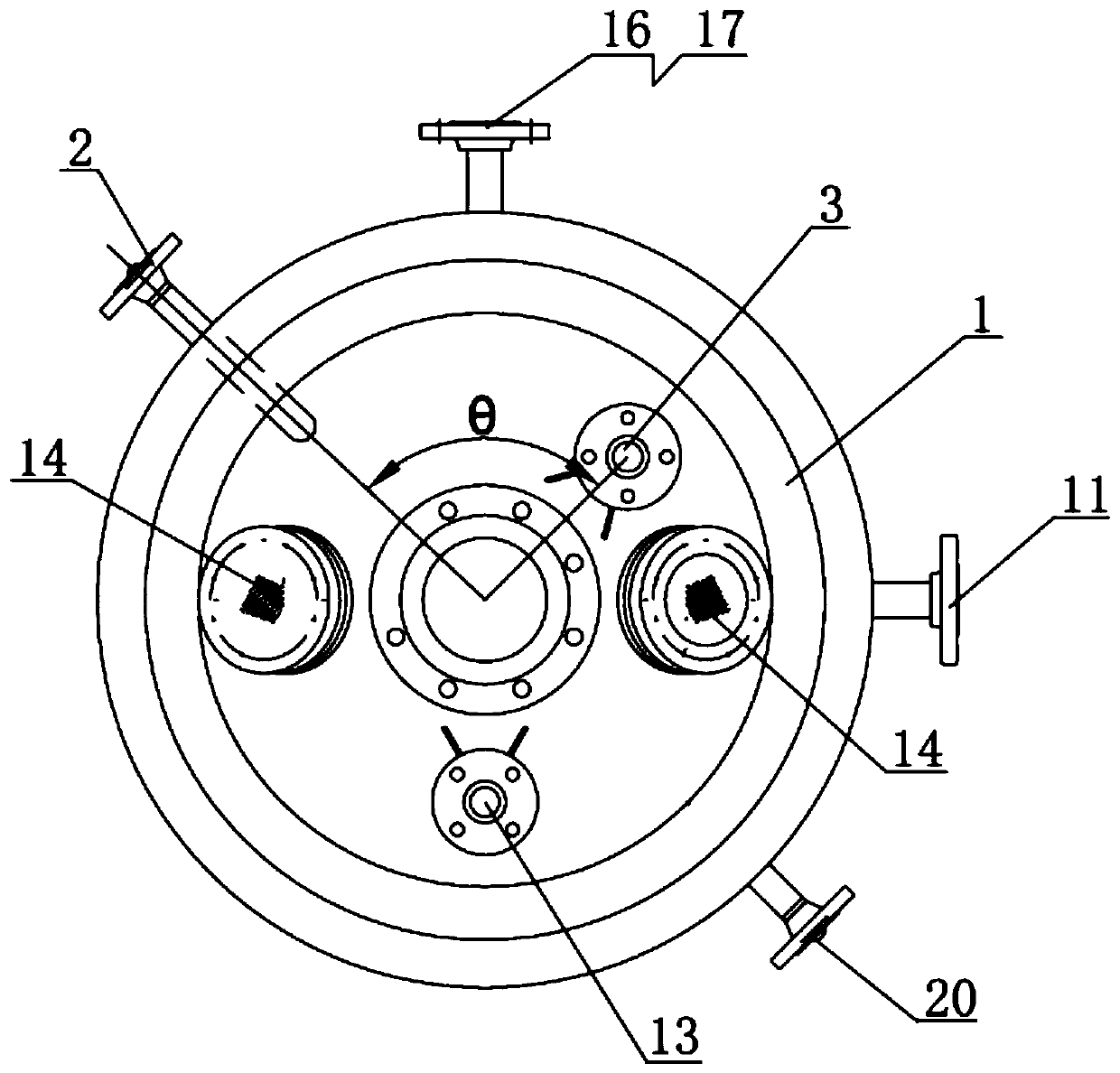

[0062] Load the crude acetal product into the continuous tank reactor 100 for pre-filling and laying the bottom, start stirring, and keep warm at 25-30°C; then turn on the diethyl methylphosphinate supply pump 200 and adjust the flow rate to 36.2kg / h, and turn on the propylene The mixed solution of aldehyde and glacial acetic acid is supplied to the pump 300 and the flow rate is adjusted to 28.8kg / h. At the same time, the flow rate of the heat exchange medium introduced into the heat exchange structure is controlled to keep the temperature in the continuous tank reactor 100 stable at 25-30°C. Reaction; the reaction product is discharged from the overflow port 11 to the temporary storage tank 400 for crude acetal. After testing, the conversion rate of diethyl methylphosphonite into acetal is 97%.

Embodiment 2

[0064] Add crude acetal to the continuous tank reactor 100 for pre-filling and laying the bottom, start stirring, keep warm at 20-25°C; then start the diethyl methylphosphinate supply pump 200 and adjust the flow rate to 36.2kg / h, and start the acrolein The mixed solution with glacial acetic acid is supplied to the pump 300 and the flow rate is adjusted to 28.8kg / h. At the same time, the flow rate of the heat exchange medium introduced into the heat exchange structure is controlled to keep the temperature in the continuous tank reactor 100 stable at 20-25°C for reaction The reaction product is discharged from the overflow port 11 to the crude acetal temporary storage tank 400. After testing, the conversion rate of diethyl methylphosphonite into acetal is 97%.

Embodiment 3

[0066] Add crude acetal to the continuous tank reactor 100 for pre-filling and bottoming, start stirring, keep warm at 15-20°C; then turn on the diethyl methylphosphinate supply pump 200 and adjust the flow rate to 36.2kg / h, and turn on the propylene The mixed solution of aldehyde and glacial acetic acid is supplied to the pump 300 and the flow rate is adjusted to 28.8kg / h. At the same time, the flow rate of the heat exchange medium introduced into the heat exchange structure is controlled to keep the temperature in the continuous tank reactor 100 stable at 15-20°C. Reaction; the reaction product is discharged from the overflow port 11 to the temporary storage tank 400 for crude acetal. After testing, the conversion rate of diethyl methylphosphonite into acetal is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com