A method for removing impurity protein in seaweed crude polysaccharide

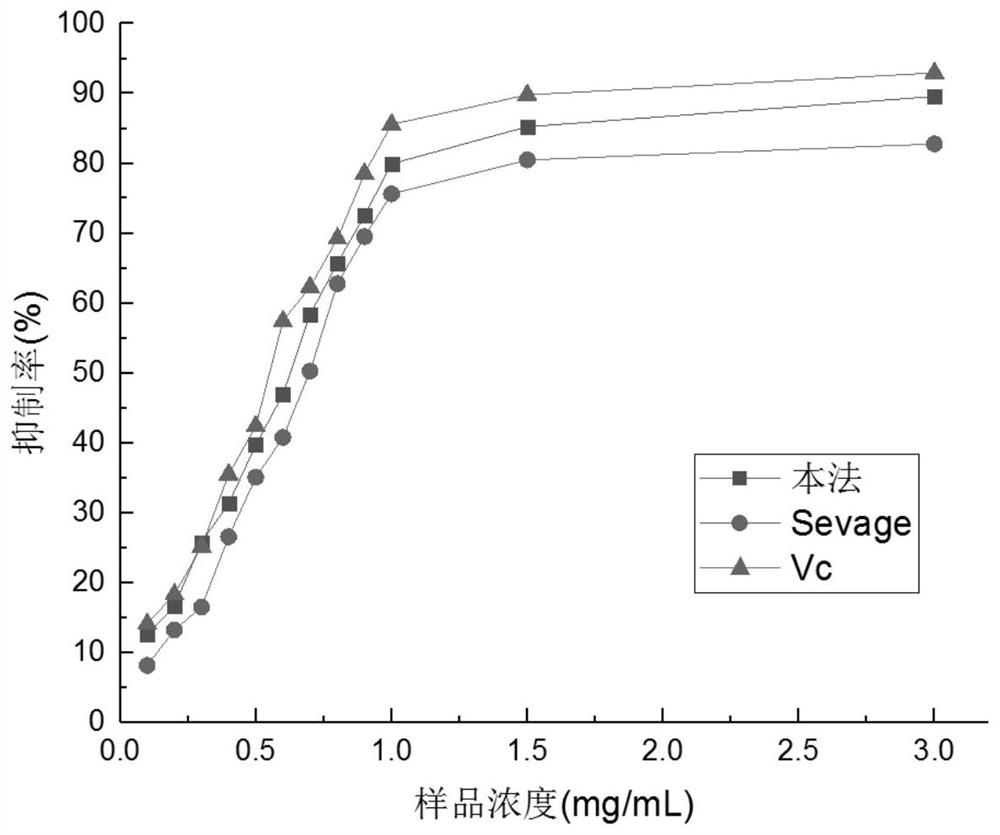

A crude polysaccharide and seaweed technology, applied in the field of comprehensive utilization of marine organisms, can solve the problems of complicated operation, limited application scope and high cost, and achieve the effects of improving polysaccharide purity, improving protein removal rate, and enhancing antioxidant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

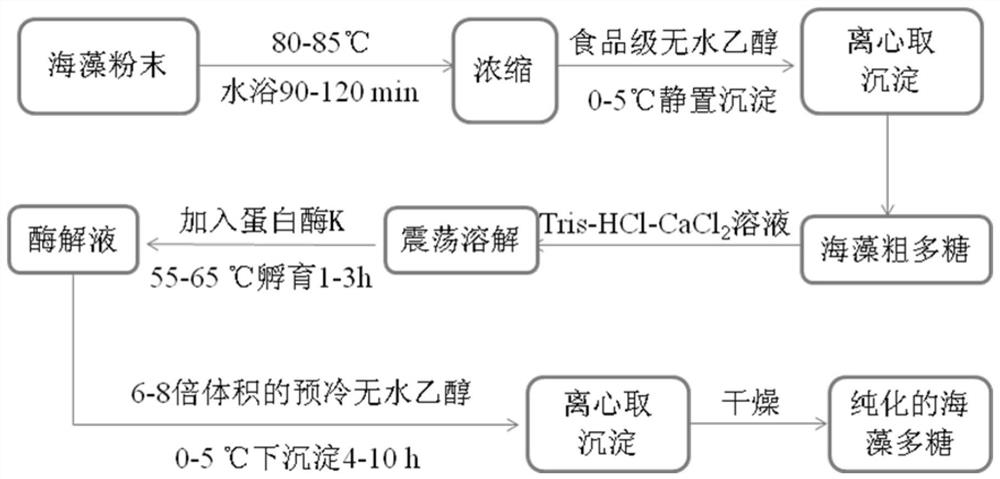

[0046] In this embodiment, the method for removing the impurity protein in the crude polysaccharide of stony coral layer algae specifically includes the following steps using stony coral layer algae as raw material:

[0047] (1) Pulverize the stony coral layer algae with a universal high-speed pulverizer for 50 seconds, and dry it at 40° C. to constant weight to obtain the stony coral layer algae powder;

[0048] (2) Weigh 10.50 g of stony coral layer algae powder, place it in a round bottom flask, add 200 mL of distilled water, stir and extract in a water bath at 85°C for 100 min, and filter to obtain the extract;

[0049] (3) Concentrate the extract with a rotary evaporator at 60°C to a water content of 15%. After cooling to room temperature, add 200mL of pre-cooled food grade ethanol, precipitate at 4°C for 5h, and centrifuge at 3000r / min for 15min. The supernatant was discarded, the precipitate was washed 3 times with food-grade ethanol, and dried in an oven at 40°C for 3 ...

Embodiment 2

[0055] In this embodiment, the method for removing the impurity protein in the crude polysaccharide of stony coral layer algae specifically includes the following steps using stony coral layer algae as raw material:

[0056] (1) Pulverize the stony coral layer algae with a universal high-speed pulverizer for 50 seconds, and dry it at 40° C. to constant weight to obtain the stony coral layer algae powder;

[0057] (2) Weigh 10.63g of stony coral layer algae powder, put it in a round bottom flask, add 300mL of distilled water, stir and extract in a water bath at 80°C for 100min, and filter to obtain the extract;

[0058] (3) Concentrate the extract with a rotary evaporator at 60°C to a water content of 15%. After cooling to room temperature, add 200mL of pre-cooled food grade ethanol, precipitate at 0°C for 5h, and centrifuge at 3000r / min for 15min. The supernatant was discarded, the precipitate was washed 3 times with food-grade ethanol, and dried in an oven at 40°C for 3 hours...

Embodiment 3

[0063] In this embodiment, the method for removing the impurity protein in the crude polysaccharide of stony coral layer algae specifically includes the following steps using stony coral layer algae as raw material:

[0064] (1) Pulverize the stony coral layer algae with a universal high-speed pulverizer for 50 seconds, and dry it at 40° C. to constant weight to obtain the stony coral layer algae powder;

[0065] (2) Weigh 10.28g of stony coral layer algae powder, put it in a round bottom flask, add 300mL of distilled water, stir and extract in a water bath at 80°C for 120min, and filter to obtain the extract;

[0066] (3) Concentrate the extract with a rotary evaporator at 55°C until the water content is 15%. After cooling to room temperature, add 200mL of pre-cooled food grade ethanol, precipitate at 2°C for 8h, and centrifuge at 3000r / min for 15min. The supernatant was discarded, the precipitate was washed twice with food-grade ethanol, and dried in an oven at 40°C for 3 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com