Water-based gray aluminum powder graphite alkyd topcoat and preparation method thereof

A technology of graphite and gray aluminum, which is applied in the field of water-based gray aluminum powder graphite alkyd topcoat and its preparation, can solve the problems of aging resistance and easy corrosion of the paint film, prolong life, improve water resistance and weather resistance, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

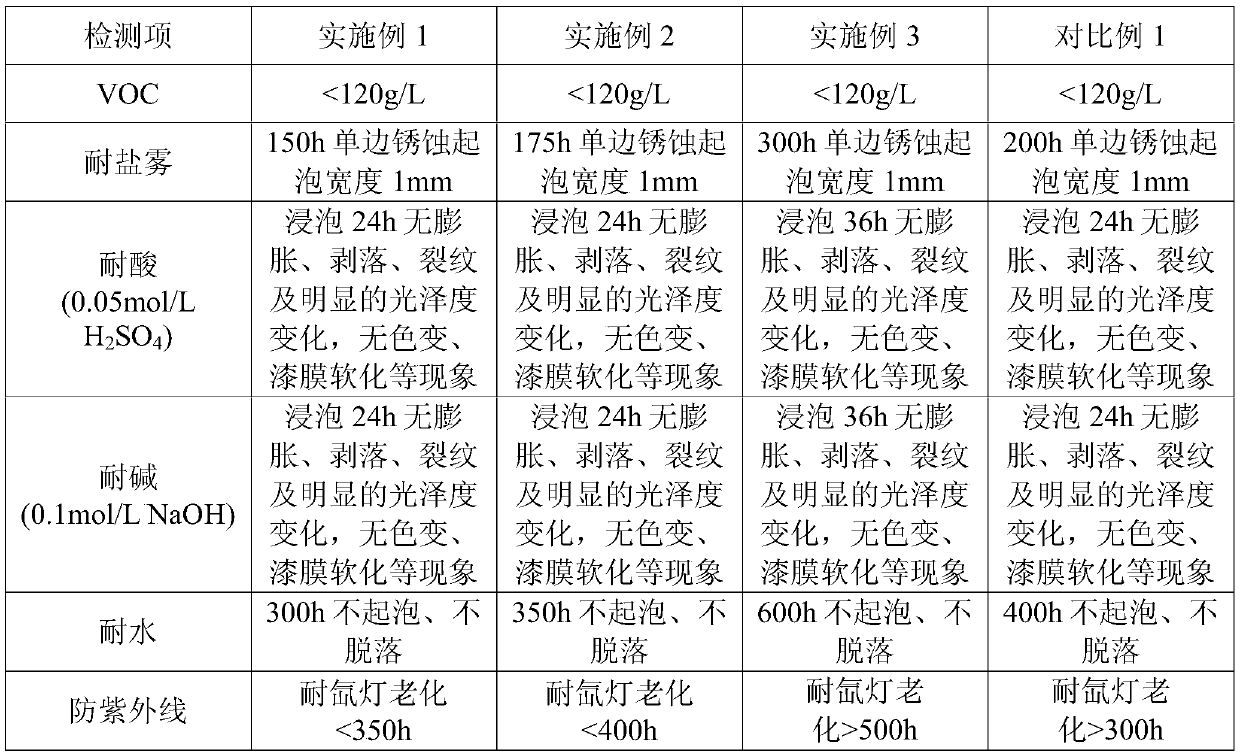

Examples

Embodiment 1

[0039] Water-based gray aluminum powder graphite alkyd topcoat, including the following components in parts by weight: 20 parts of alkyd resin, 1 part of cosolvent, 0.5 part of dispersant, 0.1 part of water-based defoamer, 0.3 part of amine neutralizer, base 1 part of material wetting agent, 6 parts of aluminum powder, 10 parts of graphite, 0.5 part of thickener, 25 parts of distilled water.

[0040] Concrete preparation steps are as follows:

[0041] (1) Add distilled water into the grinding cylinder, start stirring, add 6 parts of aluminum powder and 10 parts of graphite into 25 parts of distilled water, and stir evenly; control the speed at 800r / min, add 0.5 parts of dispersant, water-based 0.1 part of defoaming agent; after stirring evenly, transfer the feed liquid to a sand mill, grind until the fineness is less than 20 μm, and obtain aluminum powder and graphite slurry for later use;

[0042] (2) Add 20 parts of alkyd resin and 2 parts of co-solvent into the paint tank,...

Embodiment 2

[0045] Water-based gray aluminum powder graphite alkyd topcoat, including the following components in parts by weight: 24 parts of alkyd resin, 1 part of cosolvent, 0.6 part of dispersant, 0.2 part of water-based defoamer, 0.4 part of amine neutralizer, base 1 part of material wetting agent, 8 parts of aluminum powder, 18 parts of graphite, 0.8 part of thickener, 30 parts of distilled water.

[0046] Concrete preparation steps are as follows:

[0047] (1) Add distilled water into the grinding cylinder, start stirring, add 8 parts of aluminum powder and 18 parts of graphite into 30 parts of distilled water, and stir evenly; control the speed at 800r / min, add 0.6 parts of dispersant, water-based 0.2 parts of defoaming agent; after stirring evenly, transfer the feed liquid to a sand mill, grind until the fineness is less than 20 μm, and obtain aluminum powder and graphite slurry for later use;

[0048] (2) Add 24 parts of alkyd resin and 1 part of co-solvent into the paint tank,...

Embodiment 3

[0051] Water-based gray aluminum powder graphite alkyd topcoat, including the following components in parts by weight: 30 parts of alkyd resin, 1 part of cosolvent, 1 part of dispersant, 0.3 part of water-based defoamer, 0.8 part of amine neutralizer, base 3 parts of material wetting agent, 10 parts of aluminum powder, 20 parts of graphite, 1 part of thickener, 30 parts of distilled water.

[0052] Concrete preparation steps are as follows:

[0053] (1) Add distilled water into the grinding tank, start stirring, add 10 parts of aluminum powder and 20 parts of graphite into 30 parts of distilled water, and stir evenly; control the speed at 800r / min, add 1 part of dispersant, water-based 0.3 parts of defoaming agent; after stirring evenly, transfer the feed liquid to a sand mill, grind until the fineness is less than 20 μm, and obtain aluminum powder and graphite slurry for later use;

[0054] (2) Add 30 parts of alkyd resin and 3 parts of co-solvent into the paint tank, stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com