Coarsening micro-etching liquid of sulfuric acid and hydrogen peroxide system and application thereof

A technology of sulfuric acid hydrogen peroxide and hydrogen peroxide, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, can solve the problems of uneven micro-etching, uncontrollable micro-etching rate, and heterochromatic copper plate surface, etc., to achieve micro-etching The effect of stable rate, low micro-etching rate and uniform roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

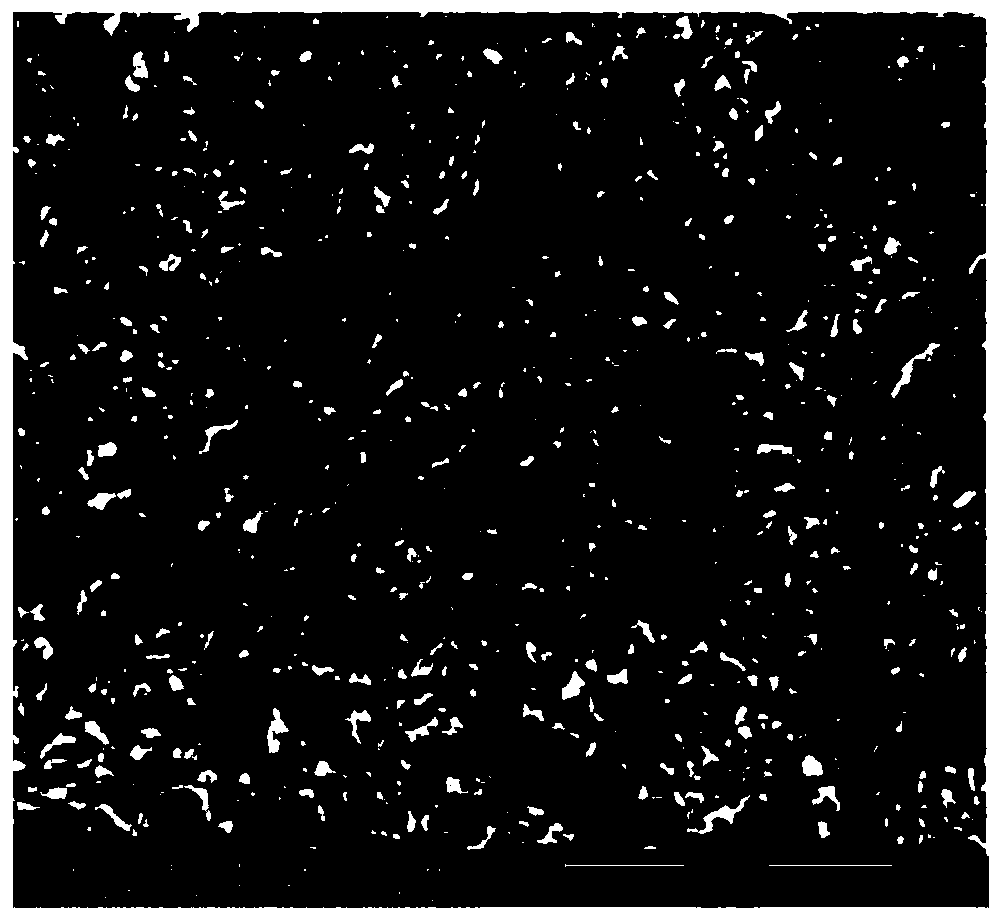

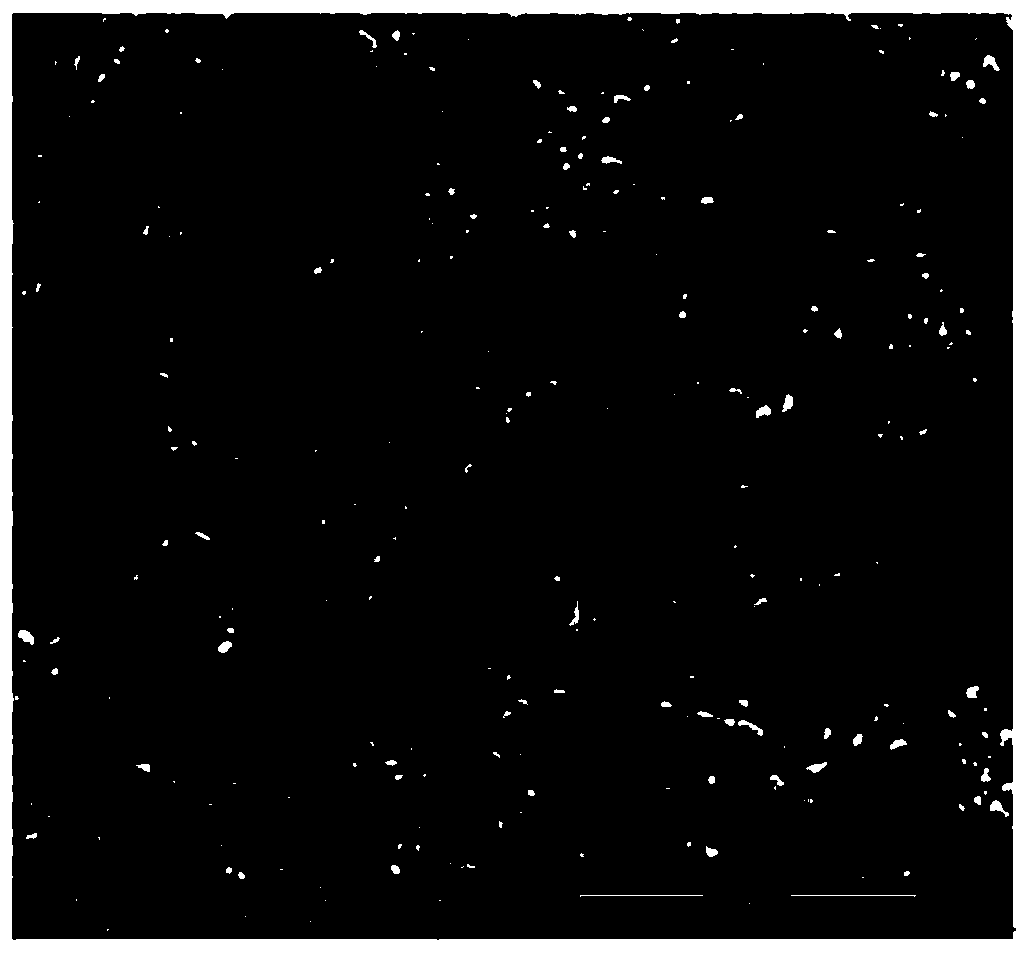

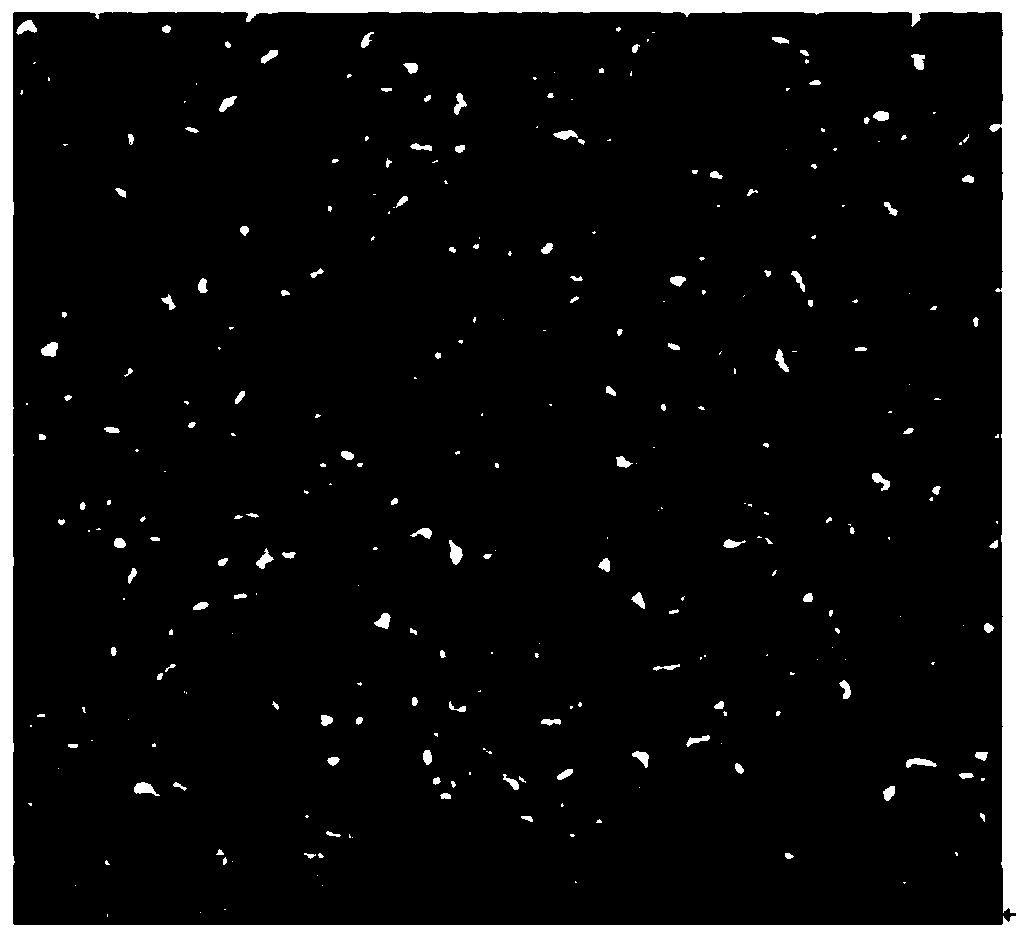

Image

Examples

Embodiment 1

[0048] This embodiment provides a roughening microetching solution of a sulfuric acid hydrogen peroxide system, and the formula of the roughening microetching solution is as follows:

[0049]

[0050] The preparation method is as follows: mix hydrogen peroxide, corrosion inhibitor, halide ion, complexing agent and water according to the above formula, stir and process, and finally add sulfuric acid to obtain the roughened microetching solution of the sulfuric acid hydrogen peroxide system .

Embodiment 2

[0052] This embodiment provides a roughening microetching solution of a sulfuric acid hydrogen peroxide system, and the formula of the roughening microetching solution is as follows:

[0053]

[0054] The preparation method is as follows: mix hydrogen peroxide, corrosion inhibitor, halide ion, complexing agent and water according to the above formula, stir and process, and finally add sulfuric acid to obtain the roughened microetching solution of the sulfuric acid hydrogen peroxide system .

Embodiment 3

[0056] This embodiment provides a roughening microetching solution of a sulfuric acid hydrogen peroxide system, and the formula of the roughening microetching solution is as follows:

[0057]

[0058] The preparation method is as follows: mix hydrogen peroxide, corrosion inhibitor, halide ion, complexing agent and water according to the above formula, stir and process, and finally add sulfuric acid to obtain the roughened microetching solution of the sulfuric acid hydrogen peroxide system .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com