Device for measuring coal bed gas content based on flow method and measuring method thereof

A coal seam gas and flow method technology, which is applied in the field of devices for measuring coal seam gas content based on the flow method, can solve the problems of gas gas diffusion, inability to obtain the original coal core, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

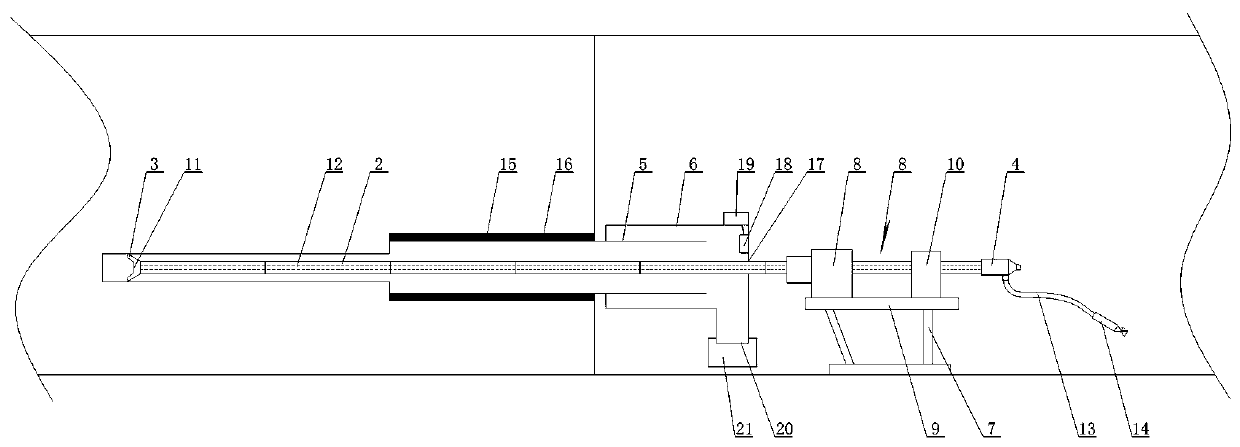

[0016] A device for measuring coal seam gas content based on the flow method, comprising a drilling rig 1, a drill pipe 2, a drill bit 3, a compressed air connector 4, a wall steel pipe 5 and a comprehensive measurement casing 6, and the drilling rig 1 is a commercially available ZDY3200S hydraulic Drilling machine, drilling machine support 7 is fixedly arranged on the ground, and drilling machine propeller 8 is installed in the drilling machine propeller slideway 9 of drilling machine support 7 upper ends, and drilling machine clamper 10 is fixedly arranged on drilling machine support 7 upper end faces. Its main points are that the middle of the drill bit 3 is provided with a pressure air port 11, the drill bit 3 is fixedly equipped with the front end of the drill rod 2, the drill rod 2 is a plurality of casing pipes that can be threaded and disassembled to connect each other, and the middle of the drill rod 2 is provided with The compressed air channel 12 , the drill propelle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com