Dynamic calibration device and method for wavelength scanning working curve of tunable laser

A technology of tuning lasers and wavelength scanning, which is used in the testing of optical performance and other directions, can solve the problems of laser wavelength control accuracy and side mode suppression ratio that cannot meet the spectral detection of fiber grating sensors, reduce detection bandwidth and implementation difficulty, and ensure consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

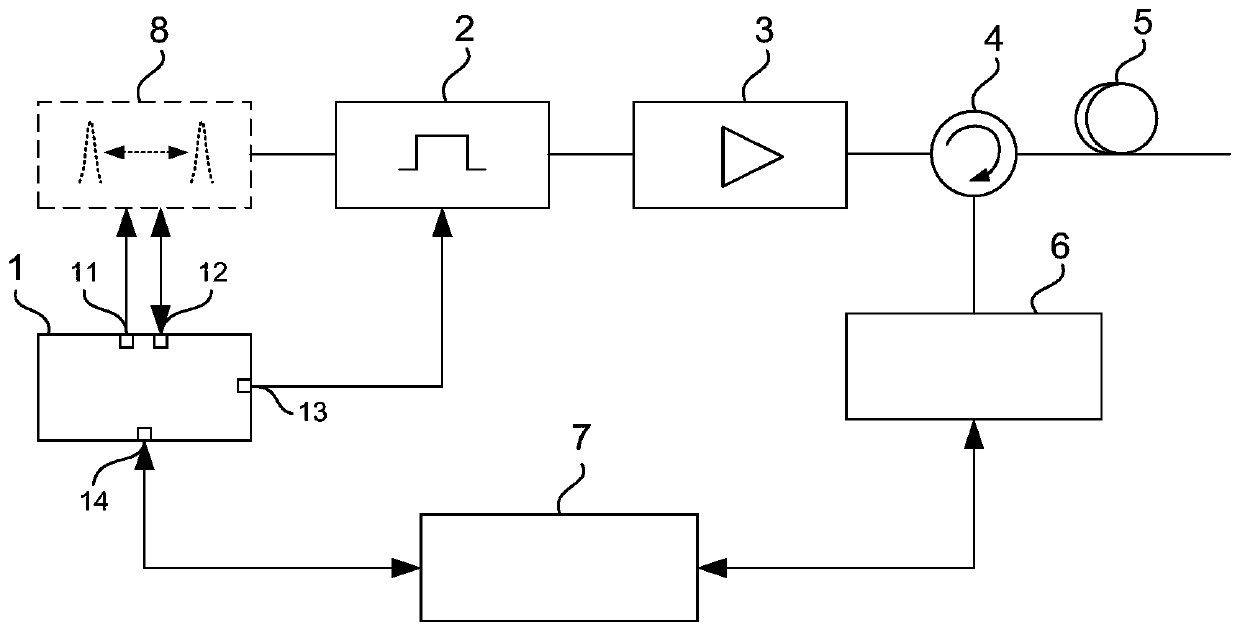

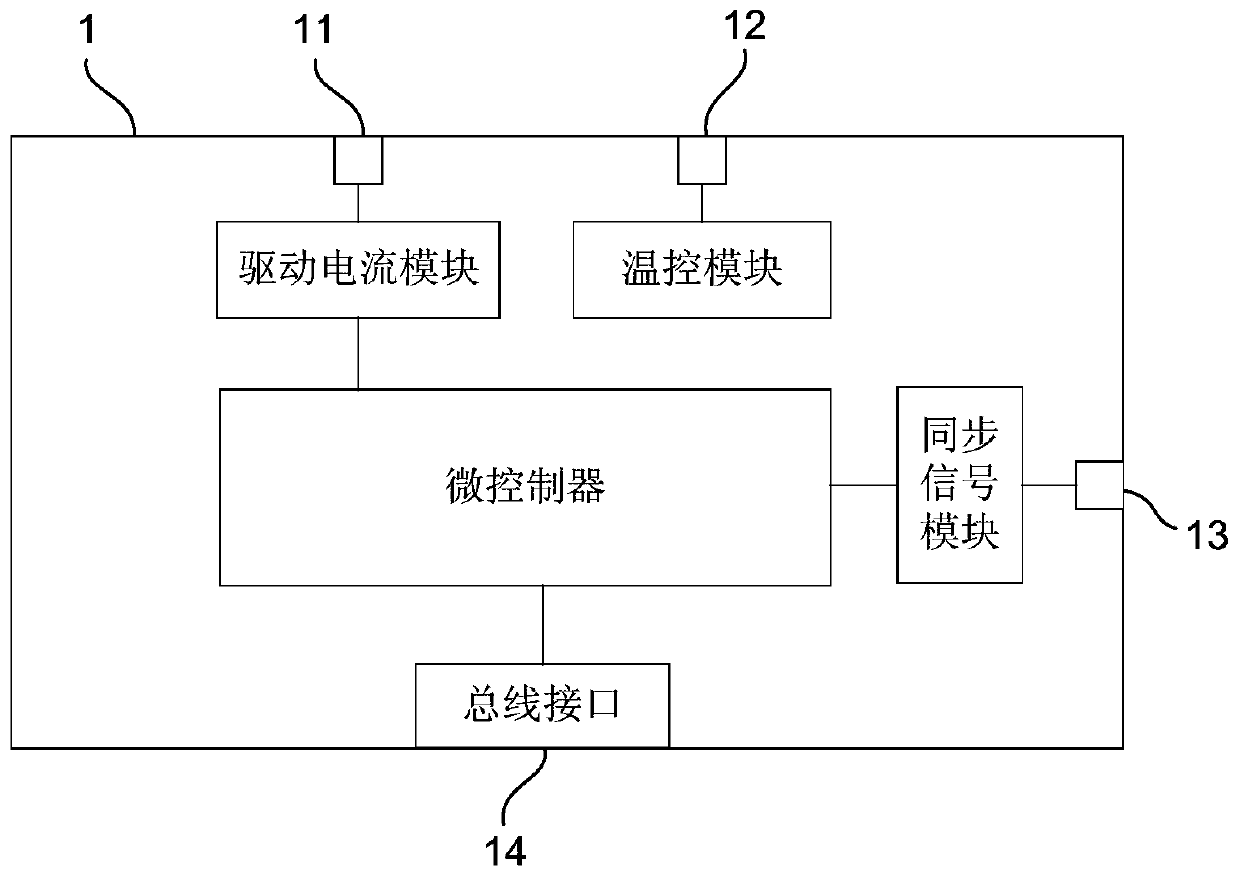

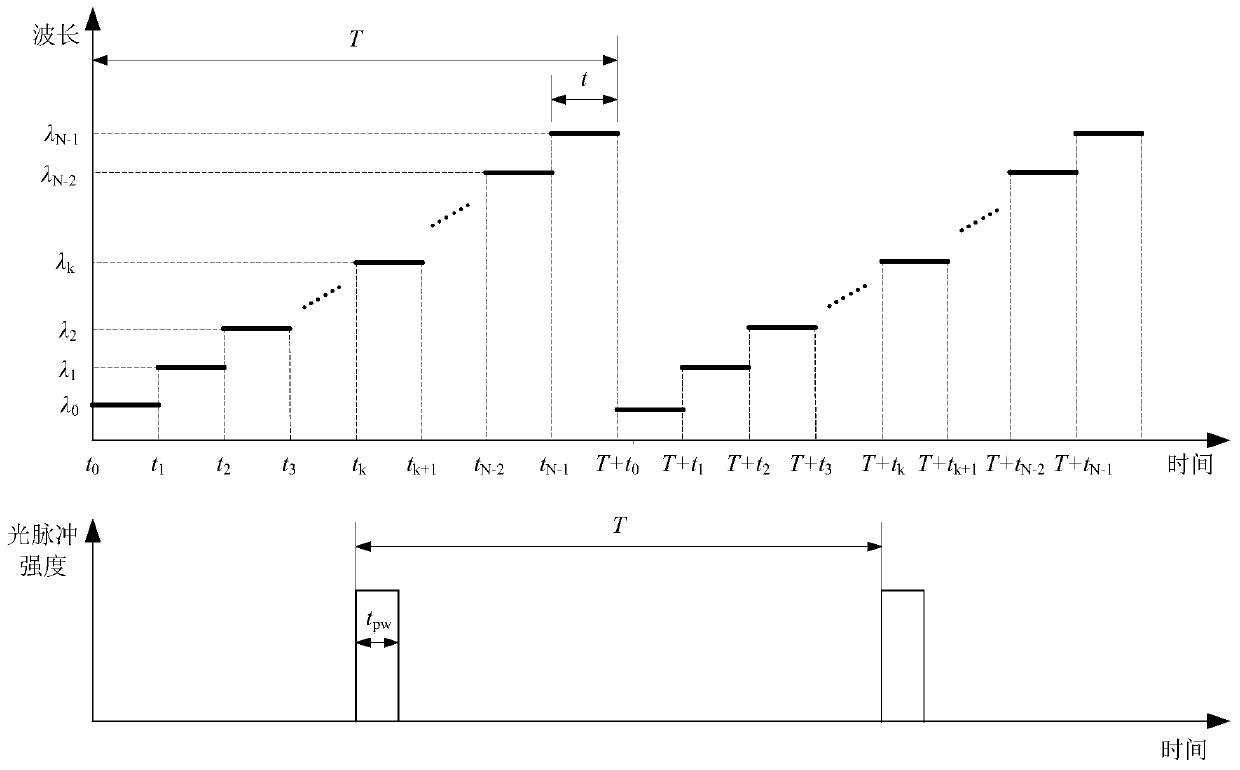

[0022] A dynamic calibration device for a tunable laser wavelength scanning working curve disclosed in the present invention, a specific embodiment is as follows figure 1 As shown; including a laser drive circuit 1, an optical pulse modulator 2, an optical amplifier 3, an optical circulator 4, an optical fiber 5, a spectrum detection unit 6, and a computer 7; the composition of the laser drive circuit 1 is as follows figure 2 As shown, it includes a bus interface, a microcontroller, a drive current module, a temperature control module, and a synchronization signal module; the drive current port 11 and the temperature control port 12 output by the laser drive circuit 1 are connected to the tunable laser 8, and the laser drive circuit 1 The synchronous signal port 13 is connected to the optical pulse modulator 2, and the bus port 14 of the laser drive circuit 1 is connected to the computer 7; the output port of the tunable laser 8 is connected to the input port of the optical pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com