Method for measuring dendritic crystal spacing of chalcogenide free-cutting steel continuous casting billet

A free-cutting steel and dendrite spacing technology, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of time-consuming and laborious, complicated experimental process, limited analysis area, etc., and achieves accurate dendrite spacing value and simple measurement method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described below in conjunction with the drawings.

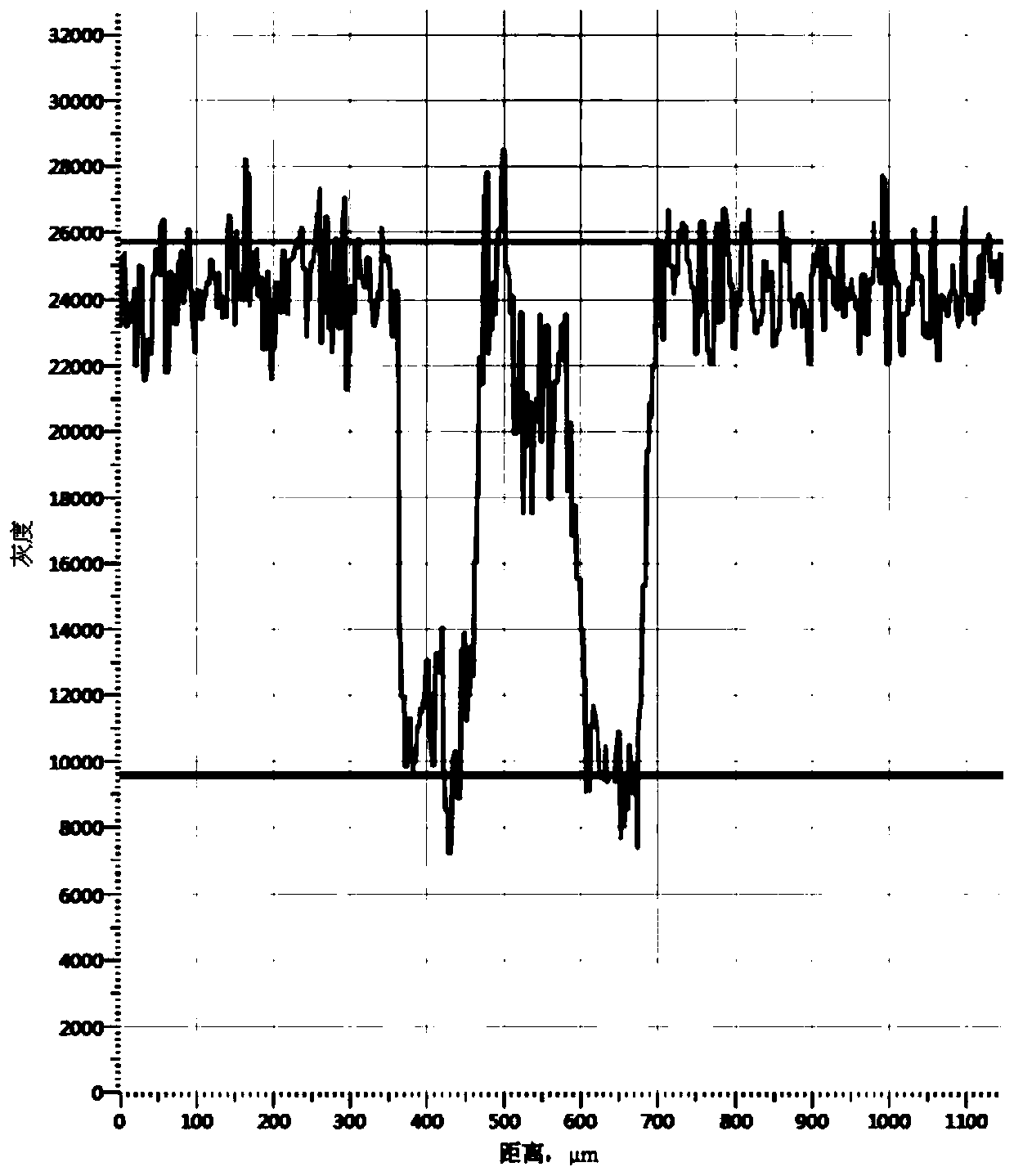

[0018] A method for measuring the dendrite spacing of continuous casting slabs of sulfur-based free-cutting steel. The specific steps and parameters are as follows:

[0019] 1. Sample preparation

[0020] First, cut a block sample from the core area of the cross section of the chalcogenide free-cutting steel continuous casting billet. The size of the sample is 30mm in length, 18mm in width, and 20mm in thickness. Then the sample is cleaned, ground and polished, and then placed Enter the scanning electron microscope sample room for analysis and testing, and set the working distance suitable for backscattered electron analysis and energy spectrum analysis to about 10mm.

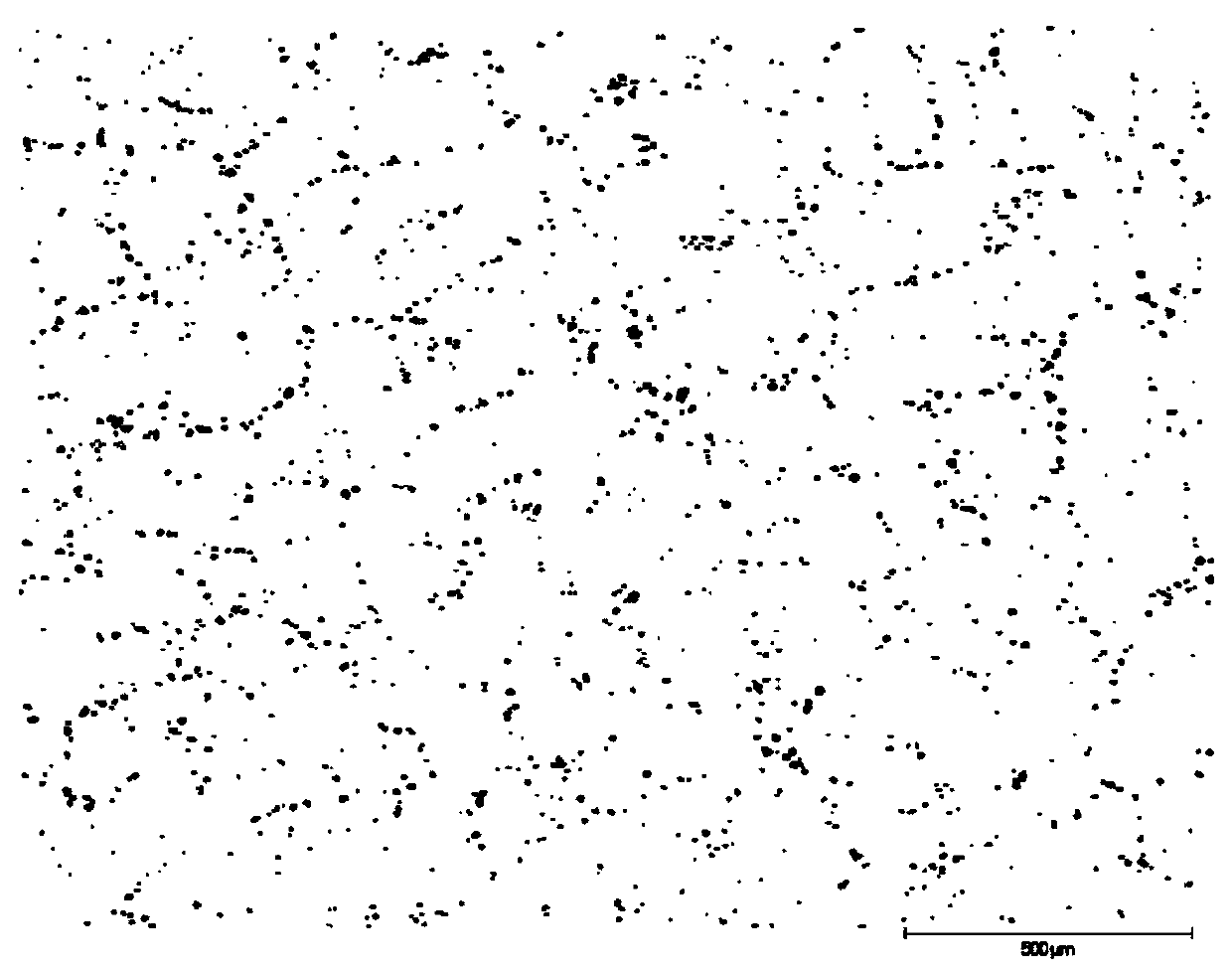

[0021] 2. Automatic statistical analysis of non-metallic inclusions in steel

[0022] Open the automatic analysis software of Aztec Steel inclusions, set the SEM acceleration voltage, probe current, mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com