Continuous production method of voltage sectional type glass-based buried optical waveguide

A production method and segmented technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of difficult performance optimization, limited capacity, and limited production efficiency of optical waveguide chips, so as to reduce investment in fixed assets and improve production efficiency , improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

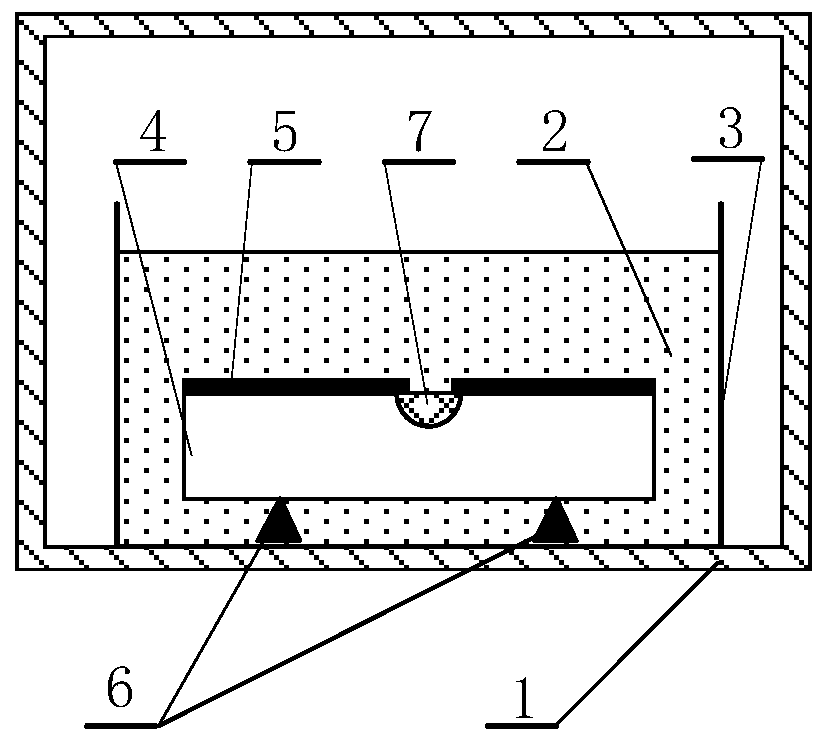

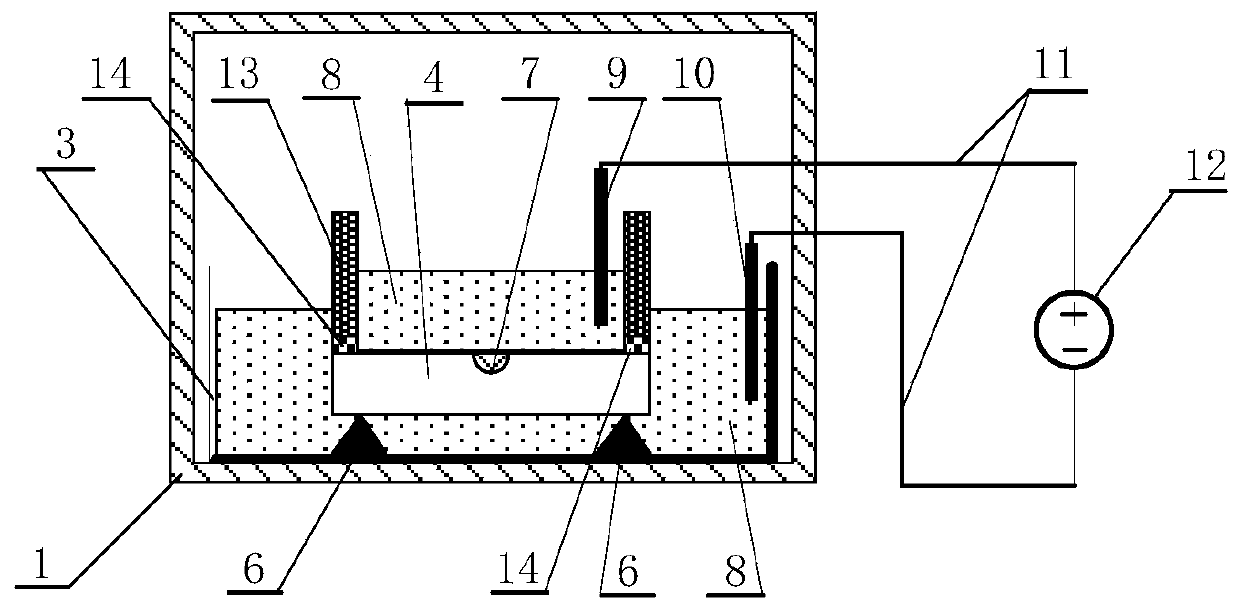

[0024] Embodiment 1: The continuous production method of the glass-based buried optical waveguide of the voltage segment type makes Ag + Doped glass-based buried single-mode optical waveguide

[0025] Required equipment: a tunnel-type high-temperature furnace 15 with a length of 6.0 meters, a conveyor belt 16, and a drive mechanism 17, consisting of a first positive electrode slide rail 181 with a length of 1.5 meters and a second positive electrode slide rail with a length of 2.0 meters 182. A positive electrode sliding rod and a negative electrode sliding rail 19 formed by sequentially connecting the third section of the positive electrode sliding rail 183 with a length of 3.0 meters, and the insulative sliding rail joint 22. Wherein the drive mechanism 17 can realize stepless speed change.

[0026] Molten salt 8 without dopant ions, here Ca(NO 3 ) 2 with NaNO 3 The mixed molten salt, the mol ratio of the two is 20:80.

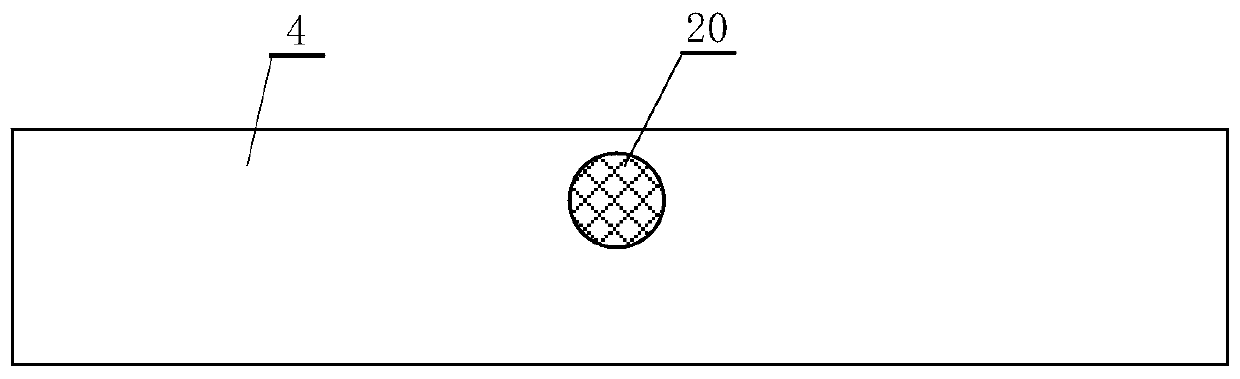

[0027] by Ag + / Na + The surface waveguide sili...

Embodiment 2

[0037] Embodiment 2: The continuous production method of voltage segmented glass-based buried optical waveguide to make Ag + Doped glass-based buried multimode optical waveguide

[0038] Required equipment: a tunnel-type high-temperature furnace 15 with a length of 6.0 meters, a conveyor belt 16, and a drive mechanism 17, consisting of a first positive electrode slide rail 181 with a length of 1.5 meters and a second positive electrode slide rail with a length of 2.0 meters 182. A positive electrode sliding rod and a negative electrode sliding rail 19 formed by sequentially connecting the third section of the positive electrode sliding rail 183 with a length of 3.0 meters, and the insulative sliding rail joint 22. Wherein the drive mechanism 17 can realize stepless speed change.

[0039] Molten salt 8 without dopant ions, here Ca(NO 3 ) 2 with NaNO 3 The mixed molten salt, the mol ratio of the two is 20:80.

[0040] by Ag + / Na + The surface waveguide silicate glass sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com