marine diesel engine

A diesel engine and engine technology, applied in engine components, combustion engines, engine control, etc., can solve the problems of NOx reduction, difficult emission reduction, and difficulty in controlling the water addition rate, so as to reduce emissions and suppress fuel efficiency deterioration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

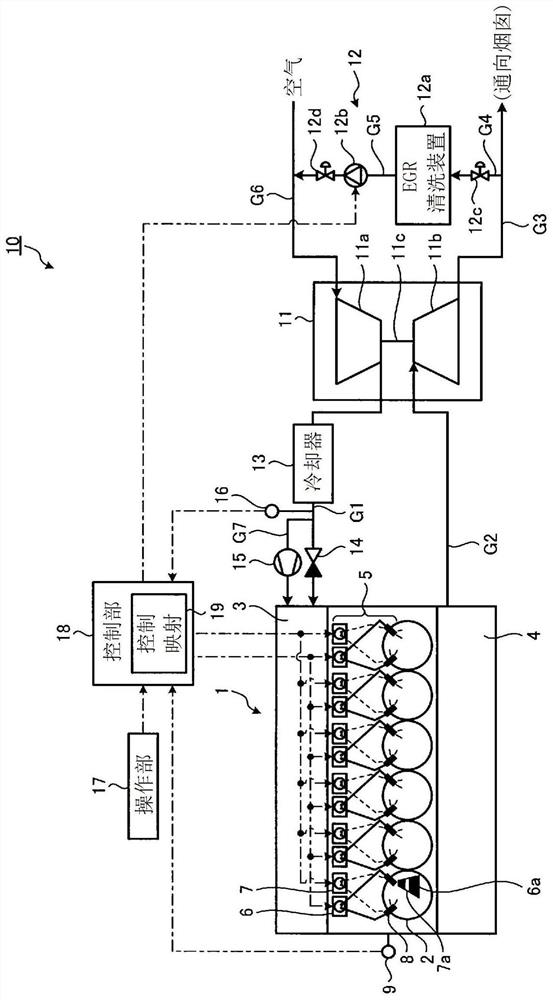

[0036] The structure of the marine diesel engine which concerns on Embodiment 1 of this invention is demonstrated. figure 1 It is a schematic diagram which shows one structural example of the marine diesel engine which concerns on Embodiment 1 of this invention. like figure 1 As shown, the marine diesel engine 10 according to the first embodiment includes an engine main body 1 , an injection unit 5 for supplying fuel and water to the engine main body 1 , and a rotational speed detecting unit 9 for detecting the rotational speed of the engine main body 1 . . In addition, the marine diesel engine 10 includes a supercharger 11 , an EGR system 12 , a cooler 13 for cooling the compressed gas from the supercharger 11 , a check valve 14 , an auxiliary blower 15 , and an auxiliary blower 15 for detecting combustion. The oxygen concentration detection unit 16 , the operation unit 17 , and the control unit 18 for the oxygen concentration of the gas. In addition, if figure 1As shown,...

Embodiment approach 2

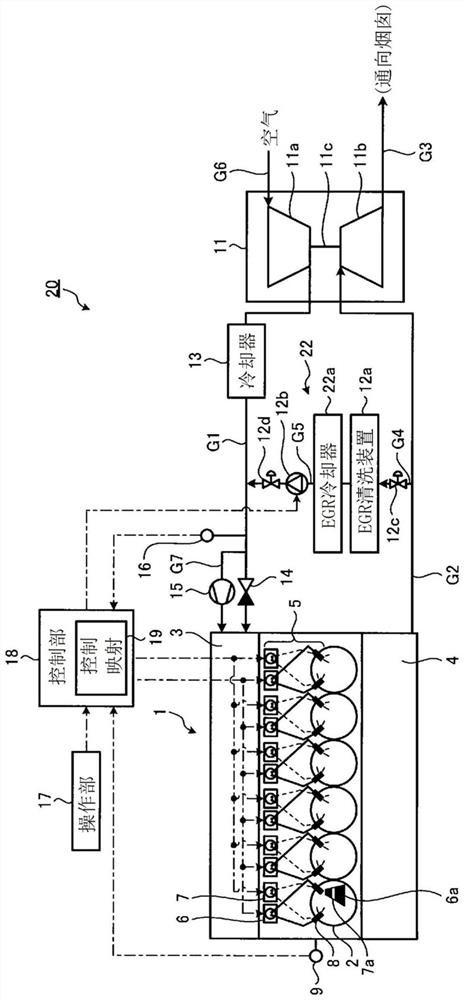

[0083]Next, Embodiment 2 of the present invention will be described. In the above-described first embodiment, the EGR operation (low-pressure EGR operation) is performed by extracting the recirculated gas from the exhaust gas whose pressure has decreased due to the rotation of the turbine 11b for the supercharger 11, but in the second embodiment , the EGR operation (high-pressure EGR operation) is performed by extracting the recirculated gas from the high-pressure exhaust gas before the turbine 11b is rotated.

[0084] image 3 It is a schematic diagram which shows one structural example of the marine diesel engine which concerns on Embodiment 2 of this invention. like image 3 As shown, the marine diesel engine 20 according to the second embodiment includes the EGR system 22 between the engine body 1 and the supercharger 11 in place of the EGR system 12 of the marine diesel engine 10 according to the first embodiment. The other structures are the same as those in Embodimen...

Embodiment approach 3

[0091] Next, Embodiment 3 of the present invention will be described. In Embodiment 1 described above, the combustion gas (specifically, fresh air or a mixed gas of fresh air and recirculated gas) is compressed by the one-stage supercharger (supercharger 11 ). In the third embodiment, the combustion gas is compressed by a two-stage supercharger.

[0092] Figure 4 It is a schematic diagram which shows one structural example of the marine diesel engine which concerns on Embodiment 3 of this invention. like Figure 4 As shown, the marine diesel engine 30 according to the third embodiment includes a two-stage supercharger 31 in place of the supercharger 11 of the marine diesel engine 10 according to the first embodiment. The other structures are the same as those in Embodiment 1, and the same symbols are attached to the same components.

[0093] The two-stage supercharger 31 is a supercharger for compressing combustion gas such as air in stages by using the exhaust gas from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com