Multi-field collaborative coupling rolling platform

A field synergy and platform technology, applied in the field of rolling processing, can solve problems such as thin surface layer thickness, achieve the effects of enhancing current density, improving current use efficiency, and optimizing stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

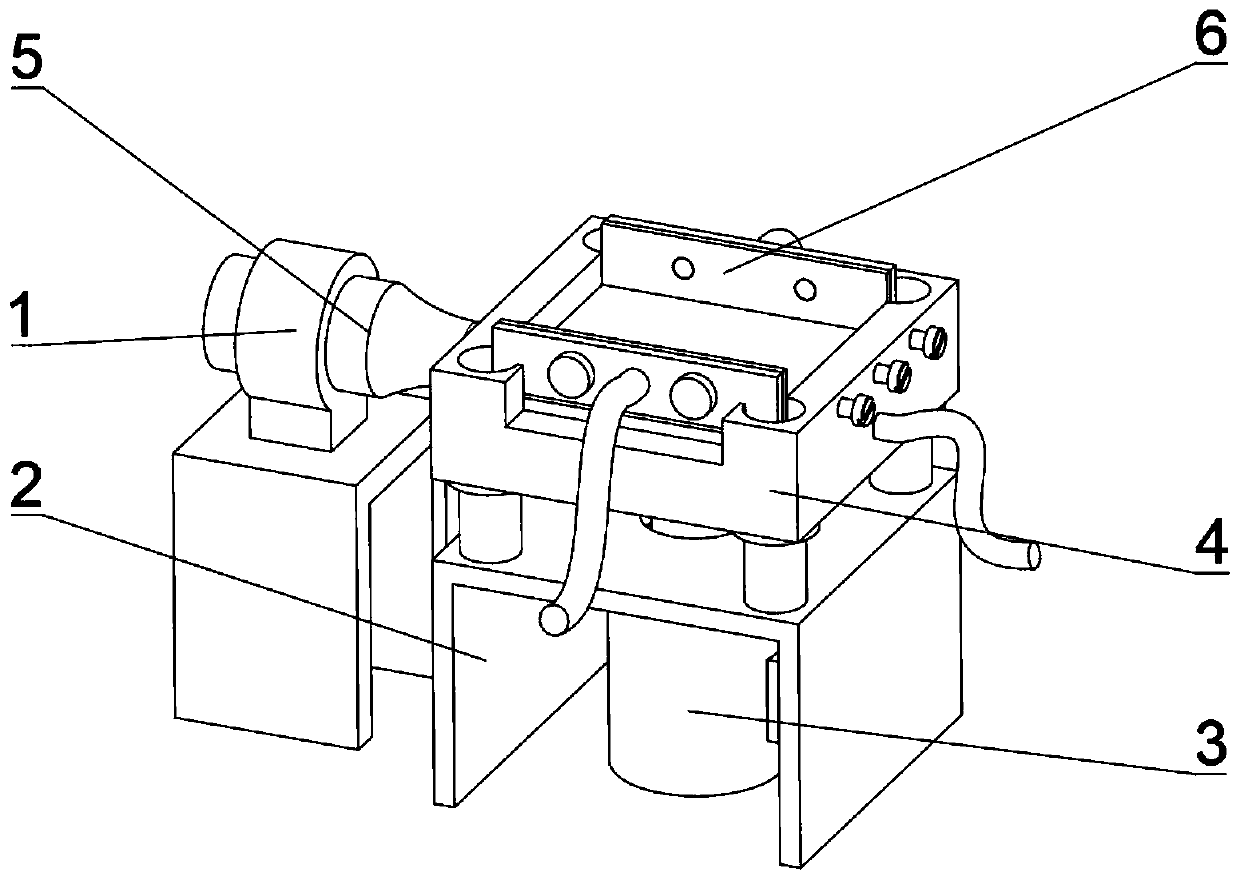

[0018] refer to Figure 1 to Figure 4 , a multi-field synergistic coupling rolling platform, including the following parts:

[0019] Main bracket 2 that mainly supports and fixes;

[0020] A transverse ultrasonic support 1 for fixing the transverse ultrasonic vibration generator;

[0021] Two ultrasonic vibration generators to realize ultrasonic vibration;

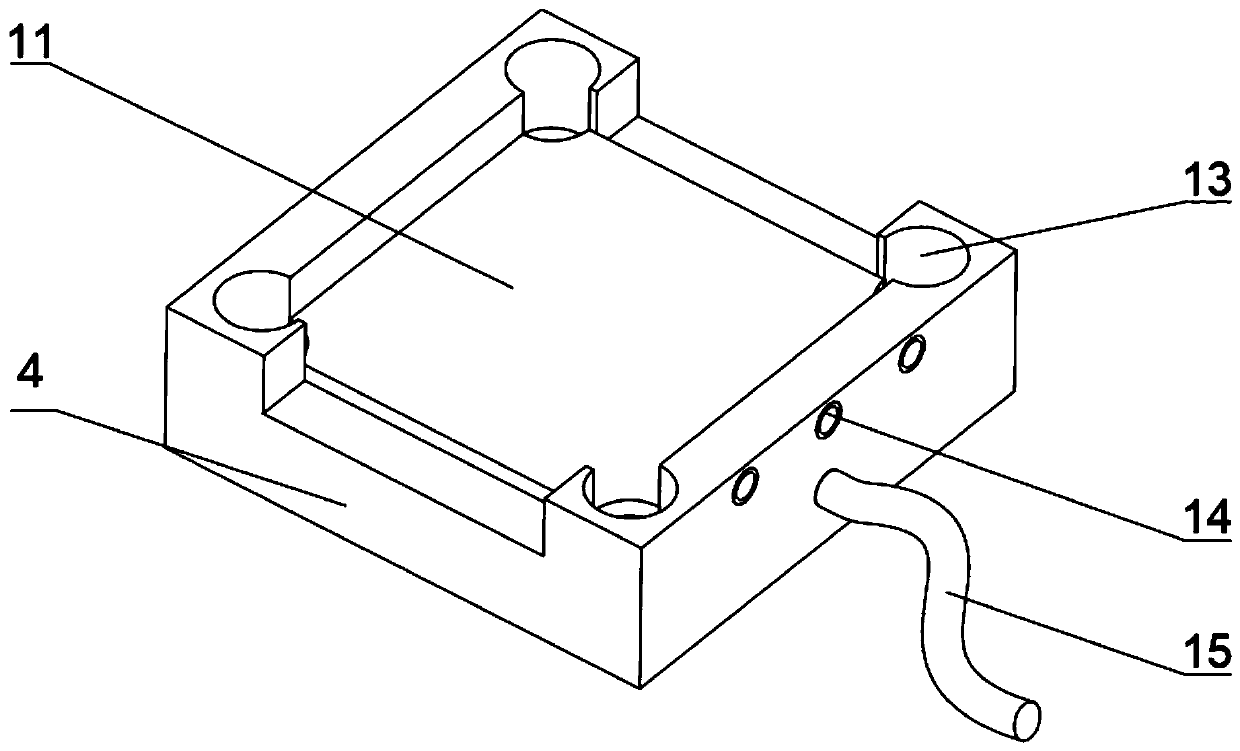

[0022] Fixture slot 4 for clamping workpiece and with permanent magnetic field;

[0023] Eddy current heating sheet 11 for realizing eddy current effect heating workpiece;

[0024] High-energy electrode assemblies 6 clamped at both ends of the workpiece.

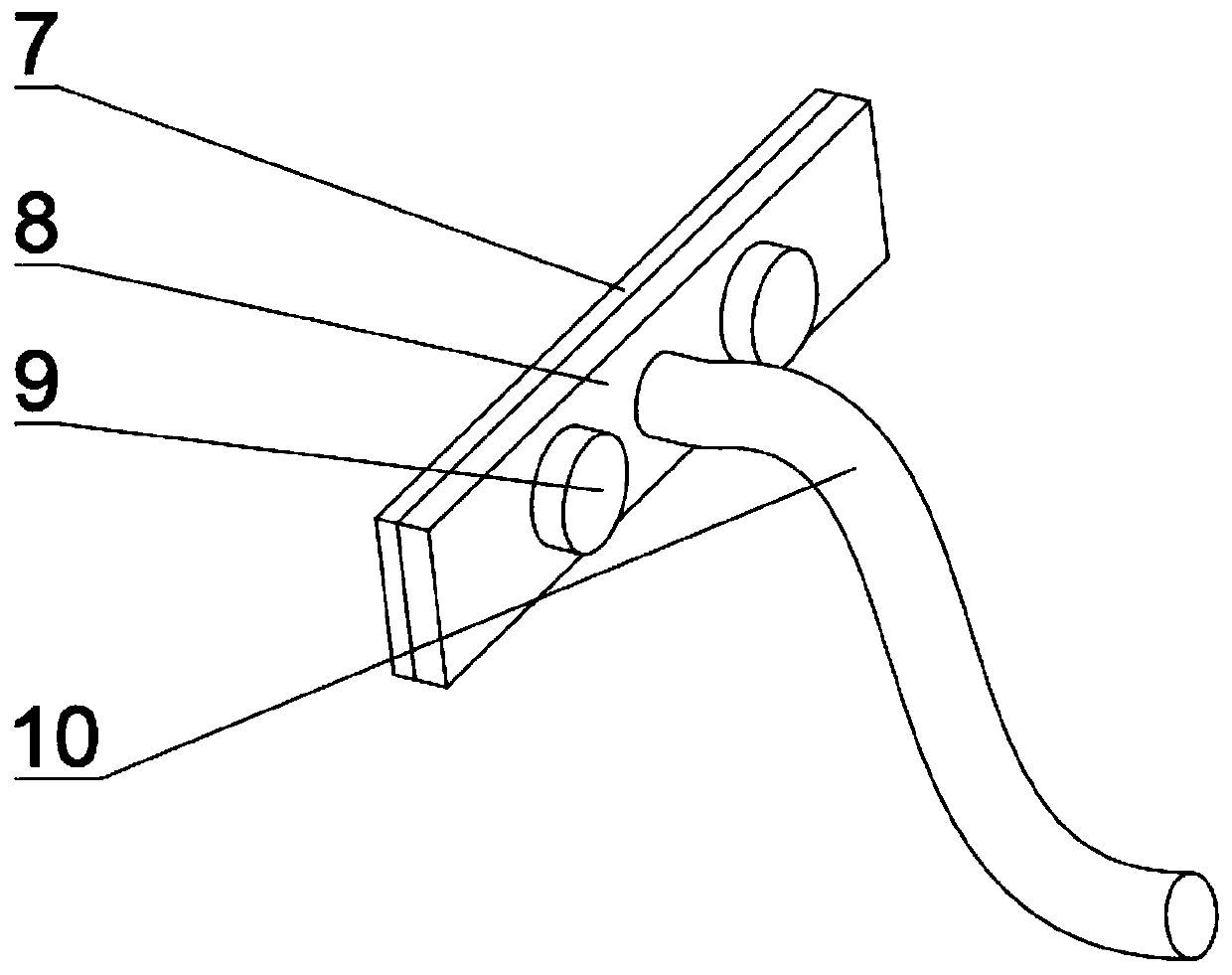

[0025] Each high-energy electrode assembly 6 includes a contact copper electrode 7 , an insulating patch 8 and a DC pulse power supply line 10 , the insulating patch 8 is arranged on the outer side of the contact copper electrode 7 , and one end of the DC pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com