Visual environment-friendly medicinal composite film based on temperature-sensitive technology, and processing technology thereof

A processing technology and composite film technology, applied in the field of pharmaceutical packaging, can solve problems such as solvent residues and packaging opaqueness, and achieve the effects of water vapor isolation, production environment safety, and excellent barrier performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

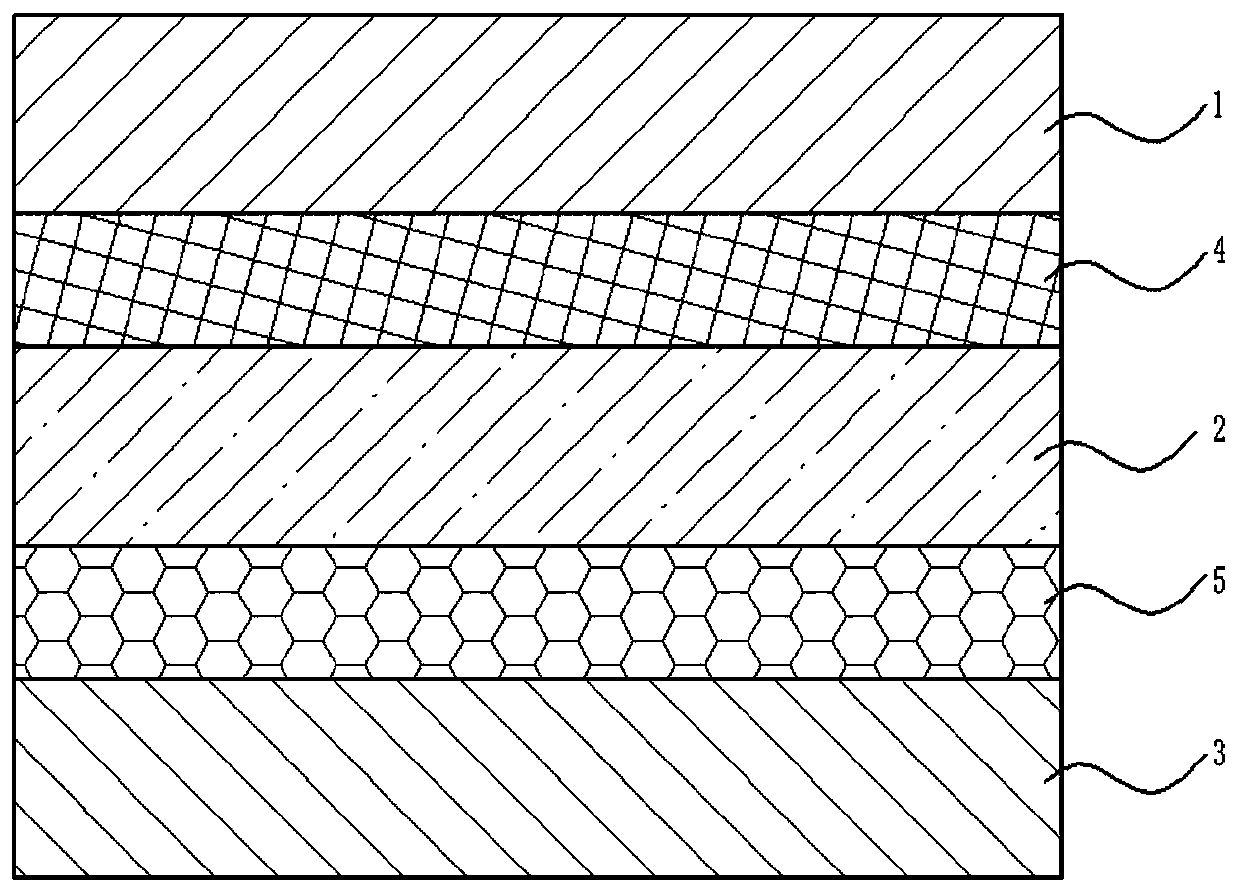

[0048] A visualized and environmentally friendly medicinal composite film based on temperature-sensitive technology. The medicinal composite film includes a first polyester film layer 1 with a thickness of 12 μm, a second polyester film layer 2 with a thickness of 12 μm and a thickness of 40 μm from top to bottom. The polyethylene film layer 3 is bonded by an adhesive layer-4 between the first polyester film layer 1 and the second polyester film layer 2, and the connection between the second polyester film layer 2 and the polyethylene film layer 3 Between by adhesive layer two 5 bonding.

[0049] A processing technology for a visualized environmental-friendly medicinal composite film based on temperature-sensitive technology, comprising the following steps:

[0050] S1: Take the first polyester film layer 1, and use embossing technology to print patterns on the surface. When printing using embossing technology, the printing speed is 120m / min, and drying treatment is carried ou...

Embodiment 2

[0057] A visualized and environmentally friendly medicinal composite film based on temperature-sensitive technology. The medicinal composite film includes a first polyester film layer 1 with a thickness of 12 μm, a second polyester film layer 2 with a thickness of 12 μm and a thickness of 45 μm from top to bottom. The polyethylene film layer 3 is bonded by an adhesive layer-4 between the first polyester film layer 1 and the second polyester film layer 2, and the connection between the second polyester film layer 2 and the polyethylene film layer 3 Between by adhesive layer two 5 bonding.

[0058] A processing technology for a visualized environmental-friendly medicinal composite film based on temperature-sensitive technology, comprising the following steps:

[0059] S1: Take the first polyester film layer 1, and use embossing technology to print patterns on the surface. When printing using embossing technology, the printing speed is 120m / min, and drying treatment is carried ou...

Embodiment 3

[0066] A visualized and environmentally friendly medicinal composite film based on temperature-sensitive technology. The medicinal composite film includes a first polyester film layer 1 with a thickness of 12 μm, a second polyester film layer 2 with a thickness of 15 μm and a thickness of 50 μm from top to bottom. The polyethylene film layer 3 is bonded by an adhesive layer-4 between the first polyester film layer 1 and the second polyester film layer 2, and the connection between the second polyester film layer 2 and the polyethylene film layer 3 Between by adhesive layer two 5 bonding.

[0067] A processing technology for a visualized environmental-friendly medicinal composite film based on temperature-sensitive technology, comprising the following steps:

[0068] S1: Take the first polyester film layer 1, and use embossing technology to print patterns on the surface. When printing using embossing technology, the printing speed is 150m / min, and drying treatment is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com